Double-sided friction stir welding cold plate and processing method thereof

A technology of friction stir welding and processing methods, applied in metal processing equipment, cooling/ventilation/heating transformation, manufacturing tools, etc., can solve problems such as increasing the complexity of processing technology, improve overall connectivity, and prevent welding shavings from entering Runner, the effect of preventing welding shavings from entering the runner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for processing a double-sided friction stir welding cold plate, comprising the following steps:

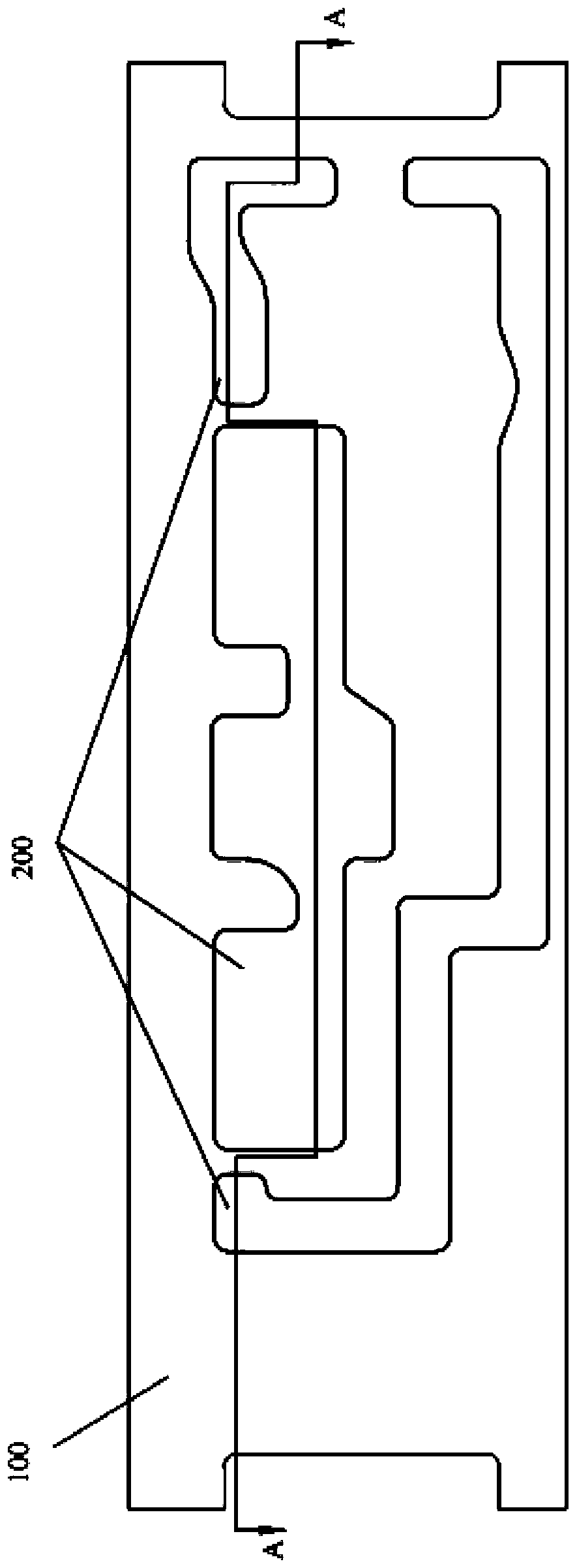

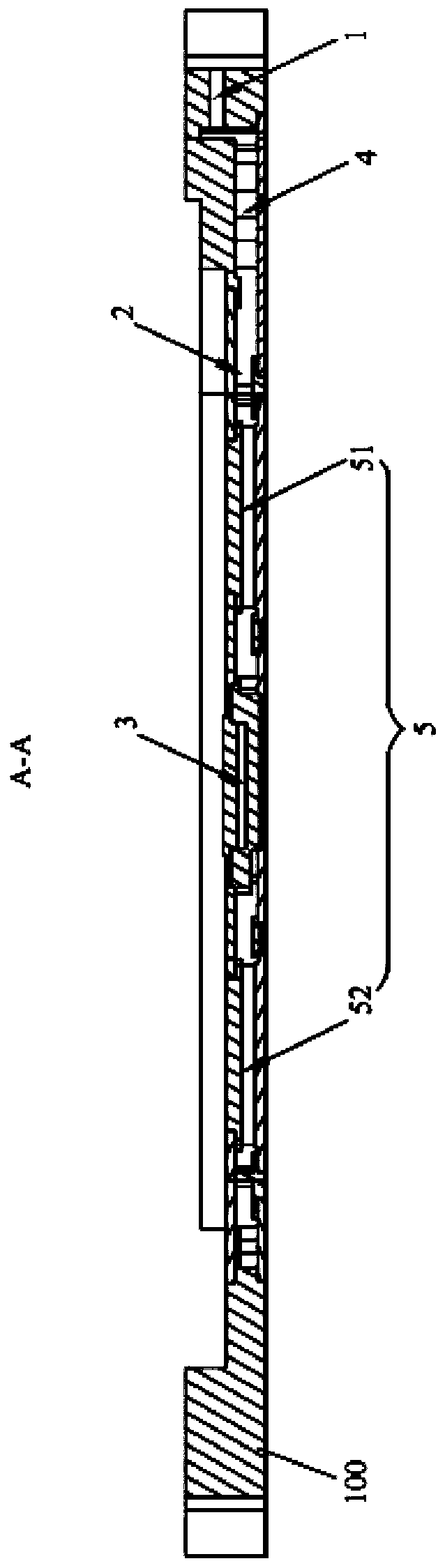

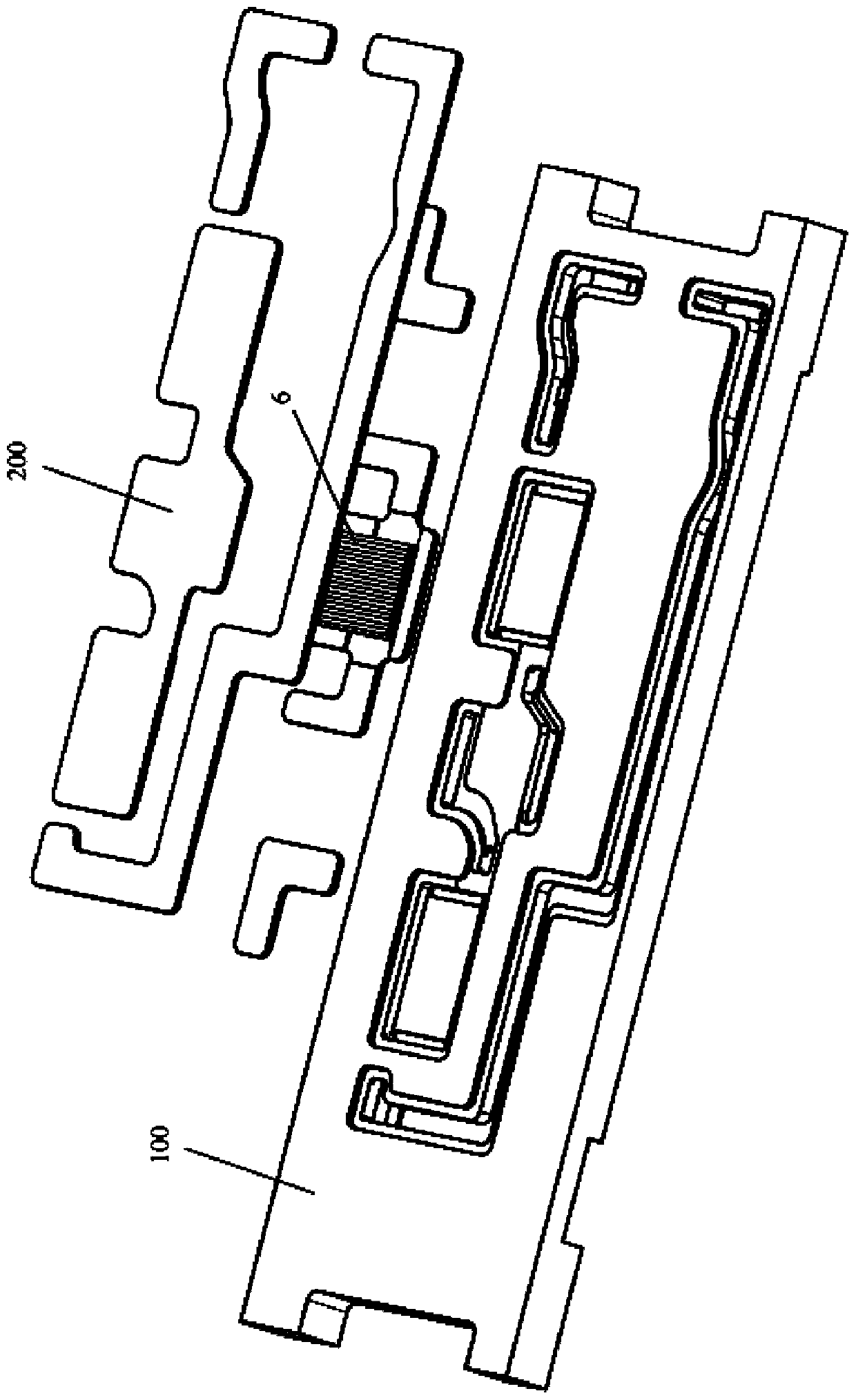

[0052] Process the flow port: process the flow port 1 on the peripheral side of the substrate 100;

[0053] Process flow channels: process a plurality of spaced upper flow channels on the upper side of the substrate 100, and process a plurality of spaced lower flow channels on the lower side of the substrate 100, the lower flow channels are connected with the upper flow channels, and the two flow channels are connected to the upper flow channels respectively The two flow ports 1 are directly connected, so that the cold flow medium enters from one flow port 1, alternately flows through the upper flow channel and the lower flow channel, and flows out from the other flow port 1;

[0054] Process the cover plate 200: design the cover plate 200 matching it according to the shape of the flow channel;

[0055]Welding forming: the cover plate 200 ...

Embodiment 2

[0083] This embodiment provides a method for processing a double-sided friction stir welding cold plate, comprising the following steps:

[0084]1. Material preparation: 100 6-series aluminum substrates, 200 main channel cover plates are 6-series aluminum materials with a thickness of 3mm, and the cover plate 200 with heat dissipation fin structure is 1-series aluminum materials, the height of the fins does not exceed 5mm, and the fin processing limit The thickness is 0.1mm, and the fin spacing is 0.2mm.

[0085] 2. Processing: the inlet and outlet are processed on the peripheral side of the substrate 100, and the flow channels are processed on the upper and lower sides of the substrate 100. The depth of the flow channels in the heat dissipation area is 0.1mm greater than the height of the fins, so as to avoid warping of the cover plate 200 during welding;

[0086] 3. Welding: Friction stir welding is used to weld along the edges of each cover plate 200, and then secondary wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com