Apatite vanadium titano-magnetite four-product beneficiation process

A technology for vanadium titanomagnetite and apatite is applied in the field of beneficiation, which can solve problems such as difficulty in obtaining economic benefits, and achieve the effects of increasing the economic benefits of beneficiation, improving quality, and realizing comprehensive and effective utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further illustrate the technical means and effects of the present invention to solve the technical problems, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the scope of protection required by the present invention.

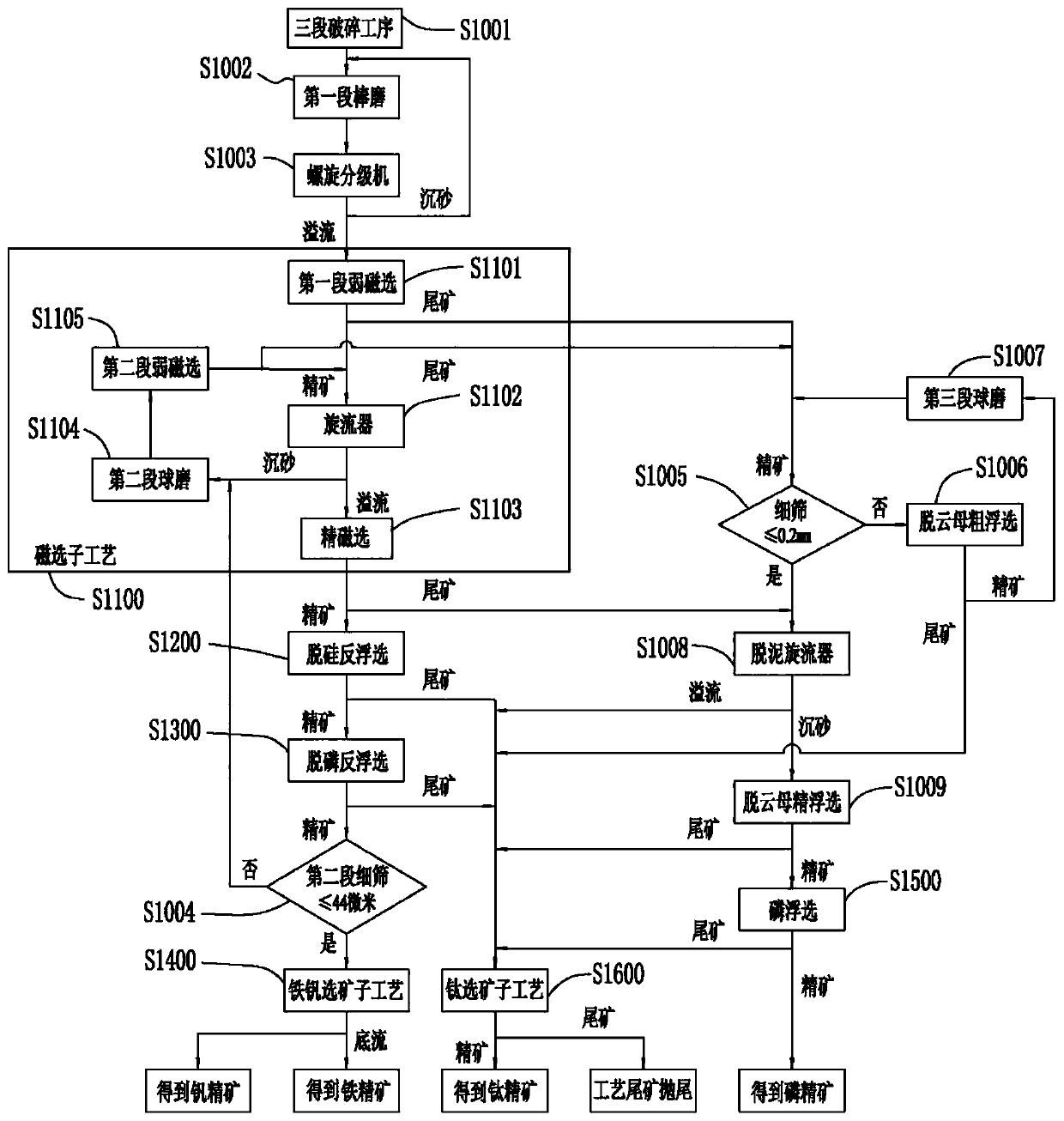

[0029] Such as figure 1 The flow chart of an optional embodiment of the apatite vanadium-titanium-magnetite four-product beneficiation process includes three stages of crushing process S1001, the first stage of rod mill S1002 and closed circuit of spiral classifier S1003, magnetic separation process S1100, desiliconization reaction Flotation S1200, dephosphorization and reverse flotation S1300, second stage fine screen S1004, iron and vanadium beneficiation sub-process S1400, third stage ball mill S1007 and fine screen S1005 closed circuit, demica coarse flotation S1006, desliming cyclone S1008, Demica fine flotation S1009, ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com