Semiconductor structure and method of forming the same

A semiconductor and conductive structure technology, applied in the field of semiconductor structure and its formation, can solve the problems of poor performance of vertical nanowire transistors and achieve high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The prior art semiconductor structures have many problems, for example, the semiconductor structures have poor performance and low integration.

[0033] Now combined with a semiconductor structure, the reasons for the low integration of the existing semiconductor structure are analyzed:

[0034] Due to the large substrate surface occupied by conventional planar transistors, the integration of the semiconductor structure is low. In order to improve the integration of the formed semiconductor structure, a vertical nanowire transistor is proposed.

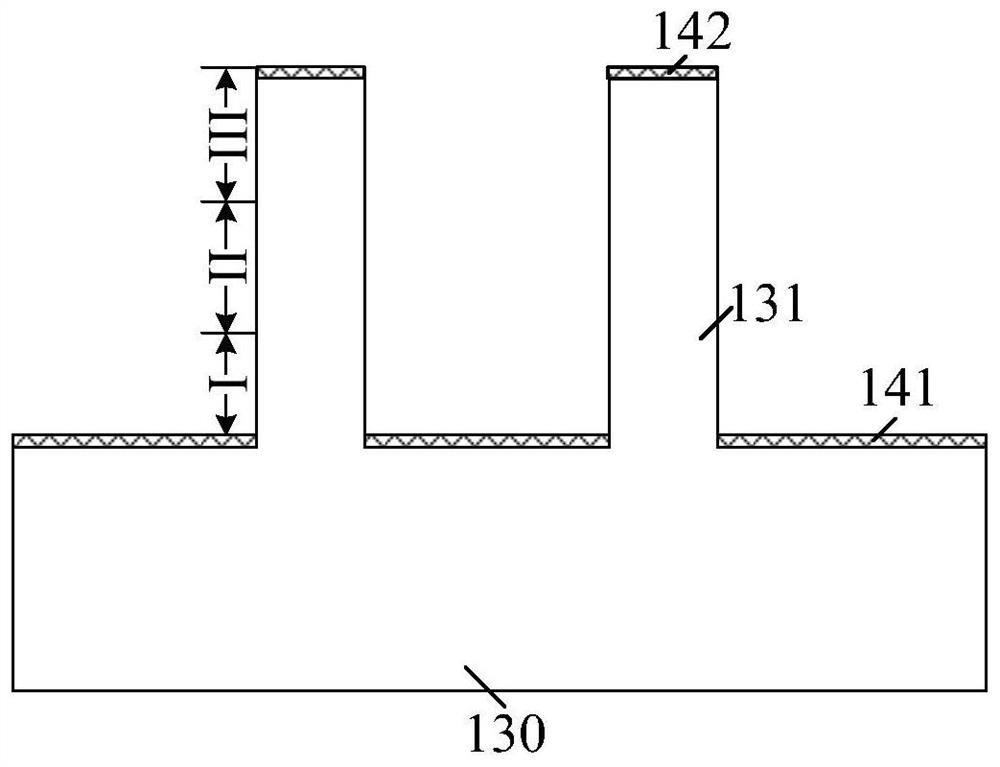

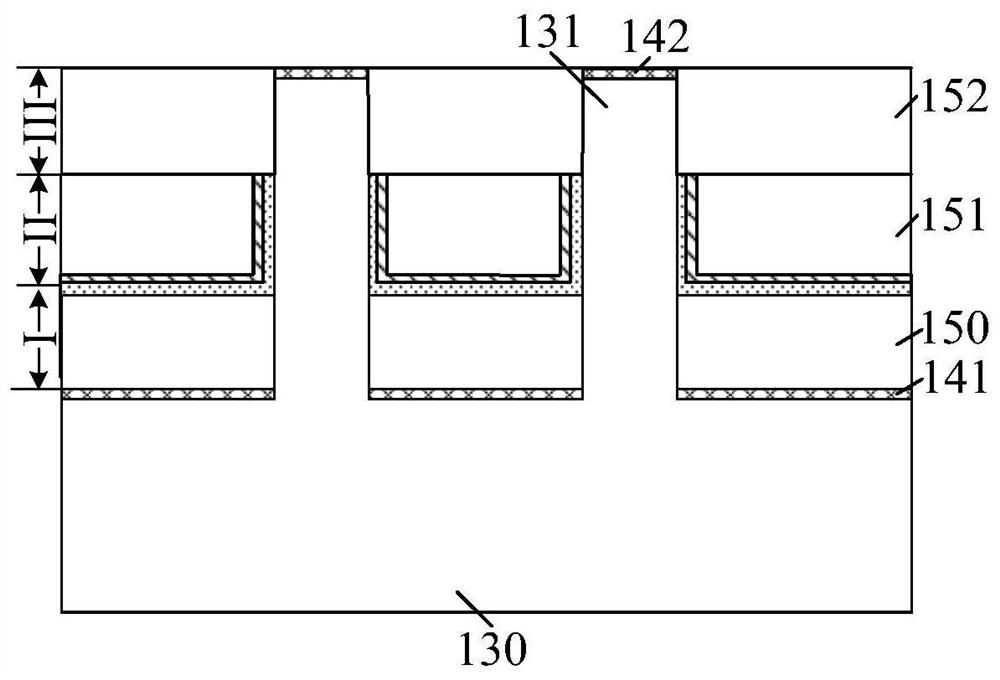

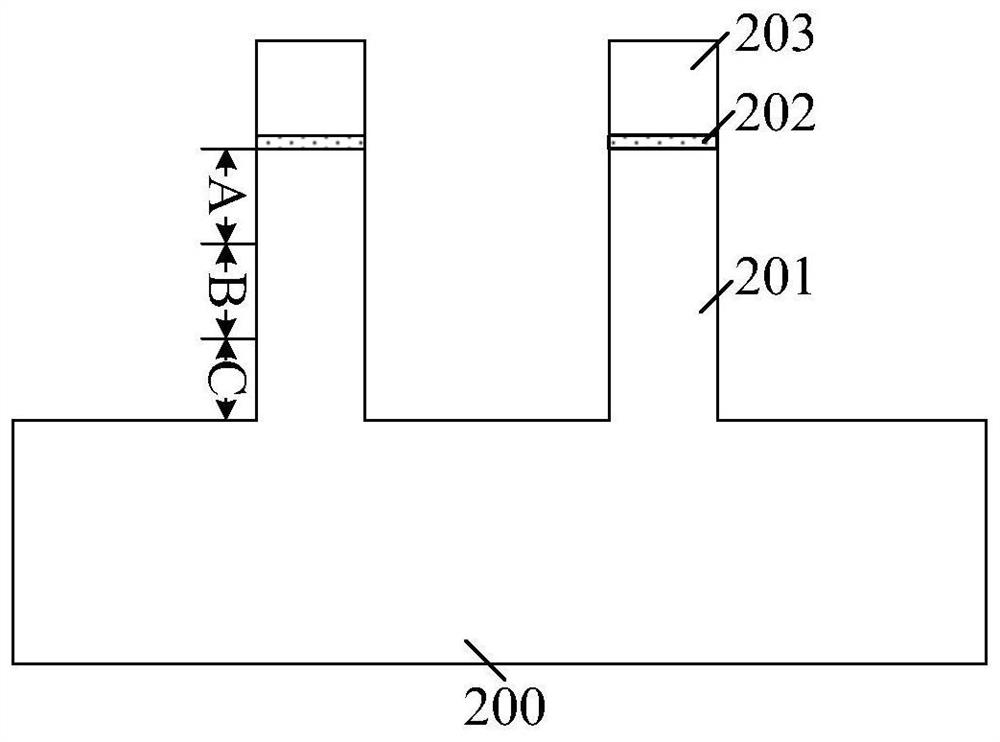

[0035] figure 1 and figure 2 It is a schematic structural diagram of each step of a method for forming a vertical nanowire transistor.

[0036] Please refer to figure 1 , a substrate 130 is provided, the surface of the substrate 130 has a fin pillar 131, the fin pillar 131 includes a bottom region I, a channel region II on the bottom region I, and a top portion on the channel region II Zone III.

[0037] continue to refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com