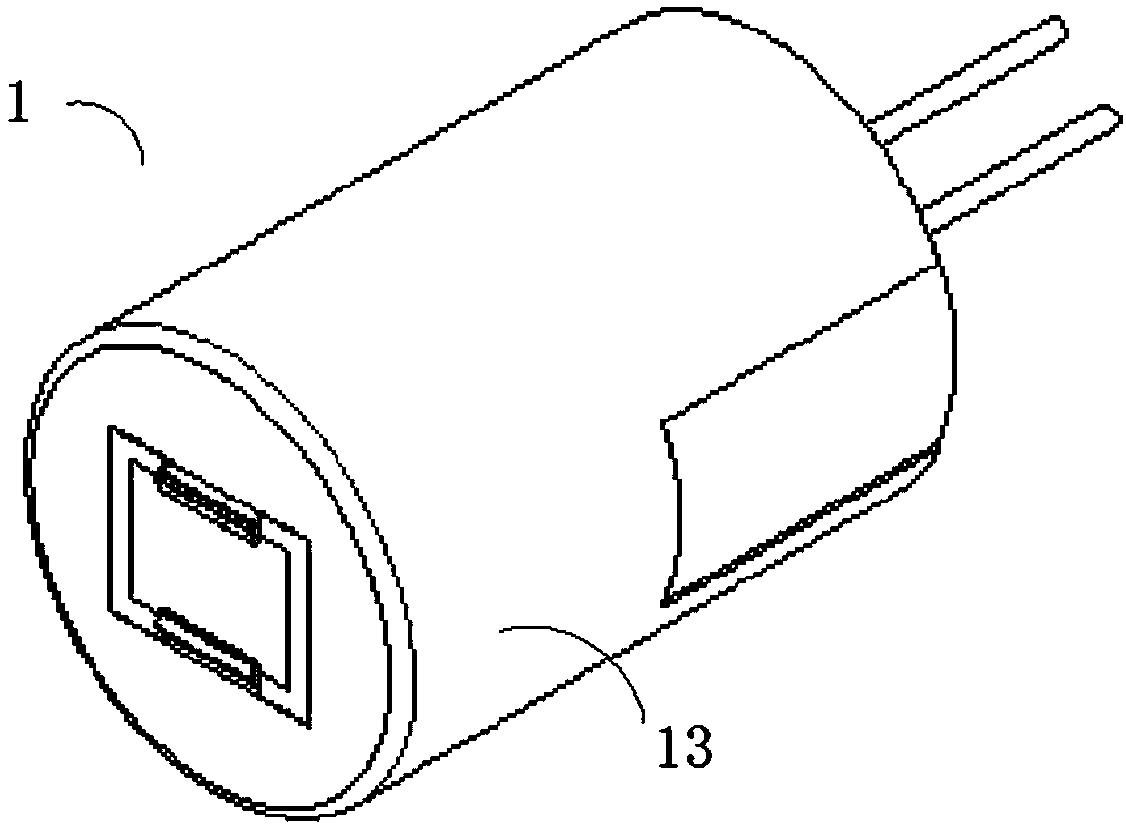

TO light source packaging device

A technology for packaging devices and light sources, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as low tolerance, prolonged working hours, and easy failure, and achieve the goal of reducing production costs, shortening processing time, and widening industrial value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

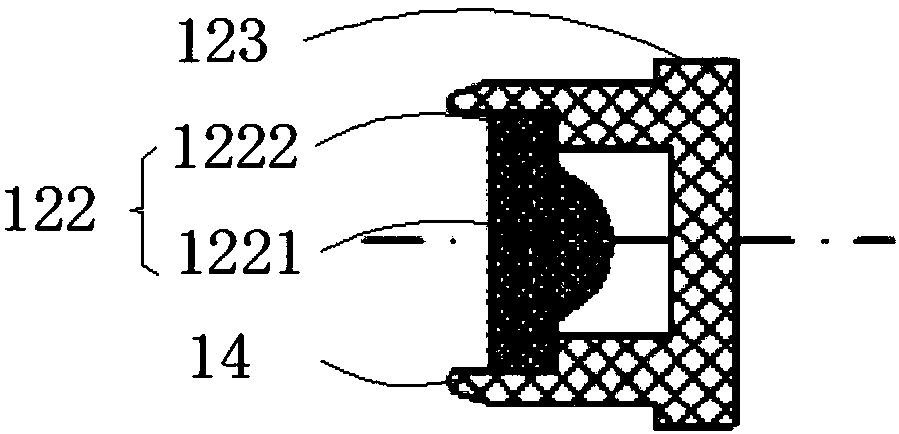

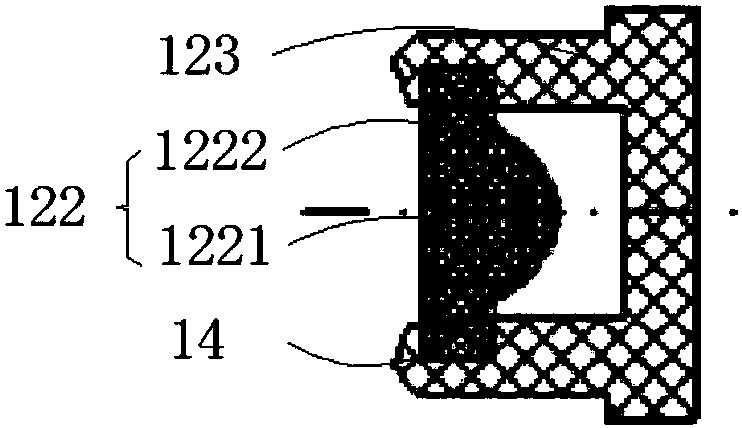

[0049] Hereinafter, various embodiments of the present disclosure will be described more fully with reference to the accompanying drawings. The present disclosure is capable of various embodiments, and adaptations and changes are possible therein. Accordingly, the present disclosure will be described in more detail with reference to specific embodiments illustrated in the accompanying drawings. It is to be understood, however, that there is no intention to limit the various embodiments of the present disclosure to the particular embodiments disclosed herein, but that the present disclosure be construed to cover those falling within the spirit and scope of various embodiments of the present disclosure. All adjustments, equivalents and / or alternatives. In conjunction with the description of the drawings, the same reference numerals designate the same elements.

[0050] Hereinafter, the terms "comprising" or "may include" that may be used in various embodiments of the present d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com