Looper roll used for rolling altitude bars and wire rod material equipment and production method thereof

A manufacturing method and technology for looper rolls, which are applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of high cost and poor processing performance of looper rolls, and can solve heat treatment deformation, improve surface hardness, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The present invention is used for the manufacture method of the looper roll of rolling height bar, wire equipment, comprises the steps:

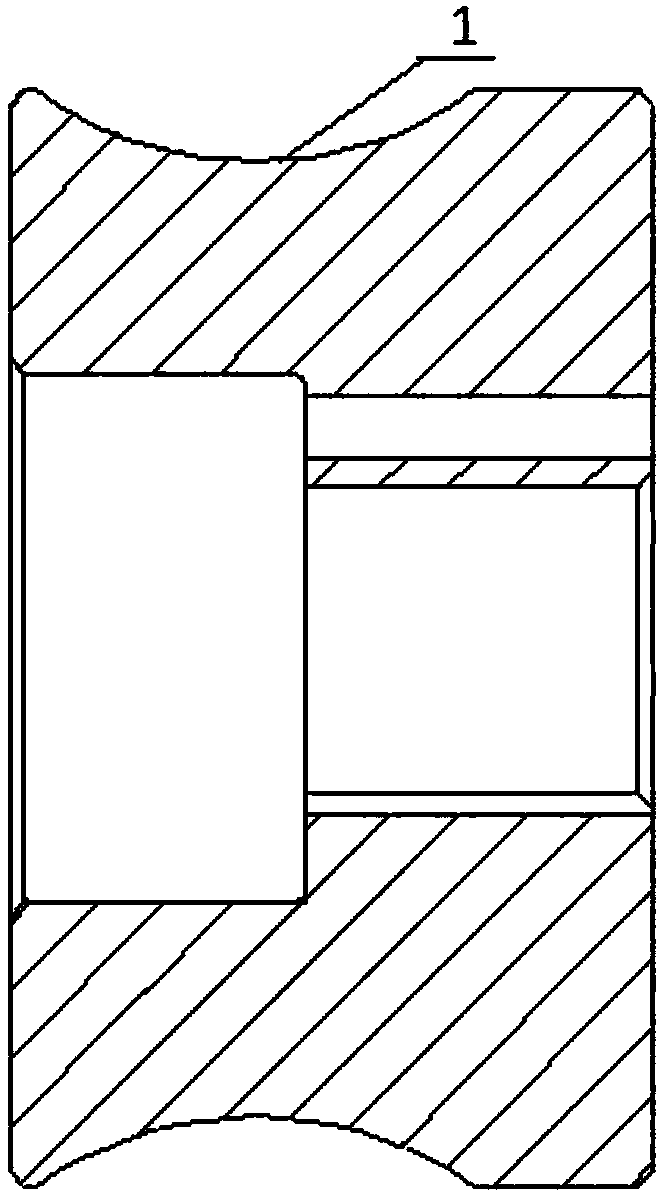

[0041] 1) According to the requirements of the drawing, the arc groove 1 of the looper roller body is processed by using the lathe with a special tool;

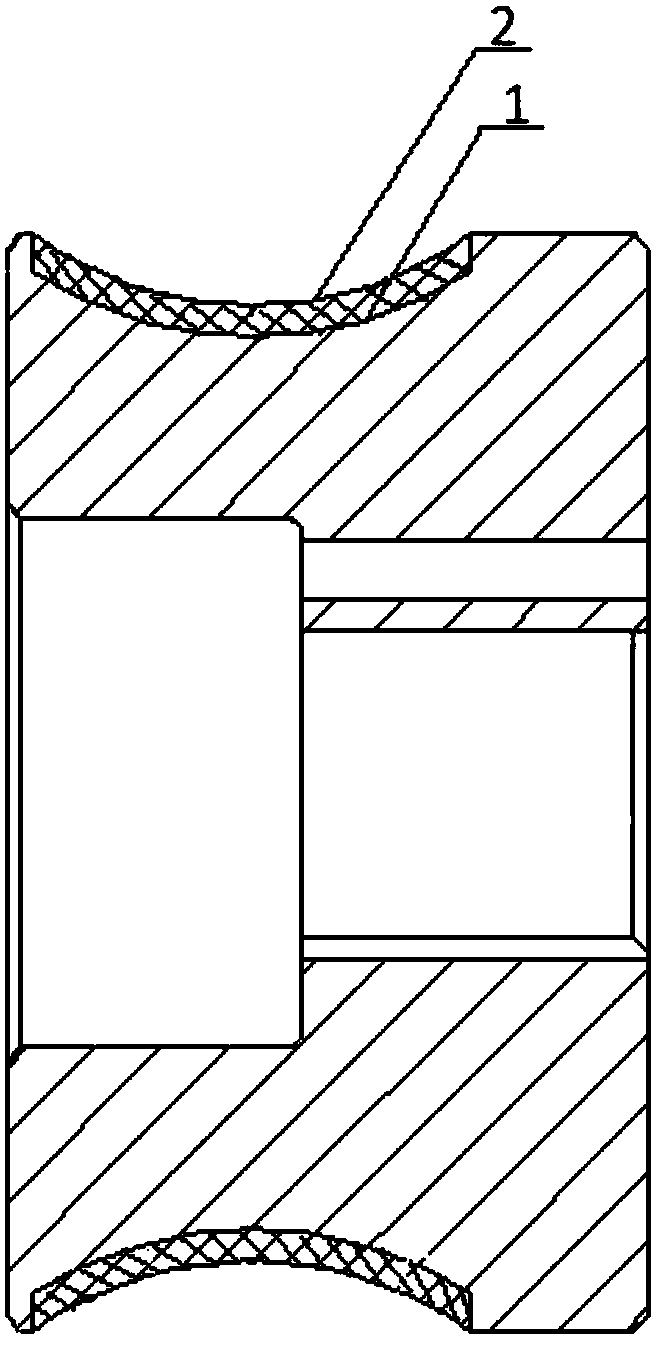

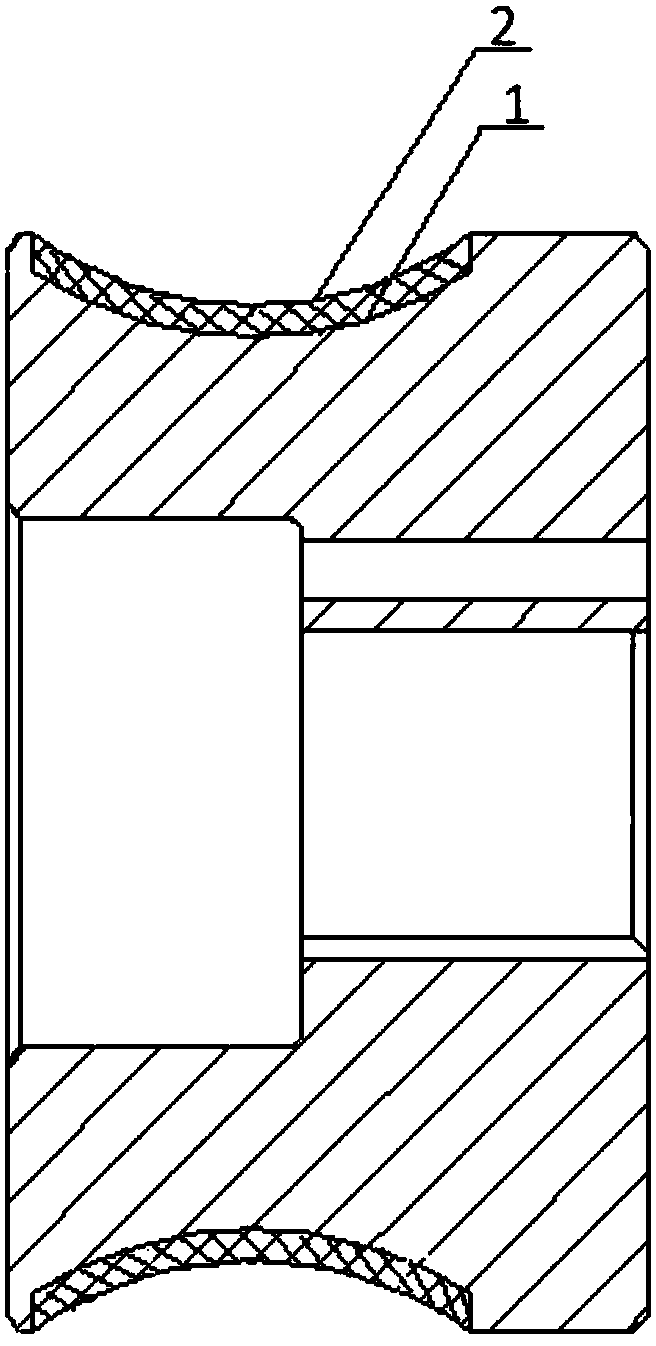

[0042] 2) Install the looper roll body with arc groove 1 obtained in step 1) on the base rotary tooling, adjust the output power of the laser to 2.3kW, so that the temperature of the laser spot area reaches the cladding temperature of 1750°C, The diameter of the light spot is 4mm, the rotating tooling of the base drives the body of the looper roller to rotate, and the speed of the rotating circle is 1mm / s, and the powder feeder sprays the powder onto the arc groove of the body of the looper roller In the laser spot area in 1, the powder is fused with the body of the looper roll, and the laser cladding layer 2 is made of powder of the same material as the body of the looper roll, the ...

Embodiment 2

[0045] The present invention is used for the manufacture method of the looper roll of rolling height bar, wire equipment, comprises the steps:

[0046] 1) According to the requirements of the drawing, the arc groove 1 of the looper roller body is processed by using the lathe with a special tool;

[0047] 2) Install the looper roller body with arc groove 1 obtained in step 1) on the base rotary tooling, adjust the output power of the laser to 2.5kW, so that the temperature of the laser spot area reaches the cladding temperature of 1800°C, The diameter of the light spot is 4mm, the rotating tooling of the base drives the body of the looper roller to rotate, and the speed of the rotating circle is 2mm / s, and the powder feeder sprays the powder onto the arc groove of the body of the looper roller In the area of the laser spot in 1, the powder is fused with the body of the looper roll. The laser cladding layer 2 is made of powder of the same material as the body of the looper rol...

Embodiment 3

[0050] The present invention is used for the manufacture method of the looper roll of rolling height bar, wire equipment, comprises the steps:

[0051] 1) According to the requirements of the drawing, the arc groove 1 of the looper roller body is processed by using the lathe with a special tool;

[0052] 2) Install the looper roller body with arc groove 1 obtained in step 1) on the base rotary tooling, adjust the output power of the laser to 2.7kW, so that the temperature of the laser spot area reaches the cladding temperature of 1850°C, The diameter of the light spot is 4mm, the rotating tooling of the base drives the body of the looper roller to rotate, and the speed of the rotating circle is 5mm / s, and the powder feeder sprays the powder onto the arc groove of the body of the looper roller In the laser spot area in 1, the powder is fused with the body of the looper roll. The laser cladding layer 2 is made of the same material powder as the body of the looper roll. The powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com