A low-mick heavy thick-wall high-tooth internal thread copper pipe and its processing tool

A technology for processing tools and internal threads, which is applied in the field of low-mick heavy-walled high-tooth internal-threaded copper pipes and their processing tools, can solve problems such as unfavorable development, increased procurement costs, and increased production costs and sales prices of internally threaded copper pipes. Achieve the effect of avoiding high flaw detection curve, reducing production cost and selling price, and reducing purchase quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

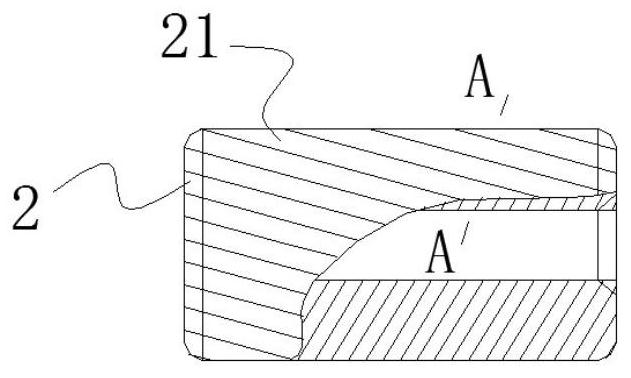

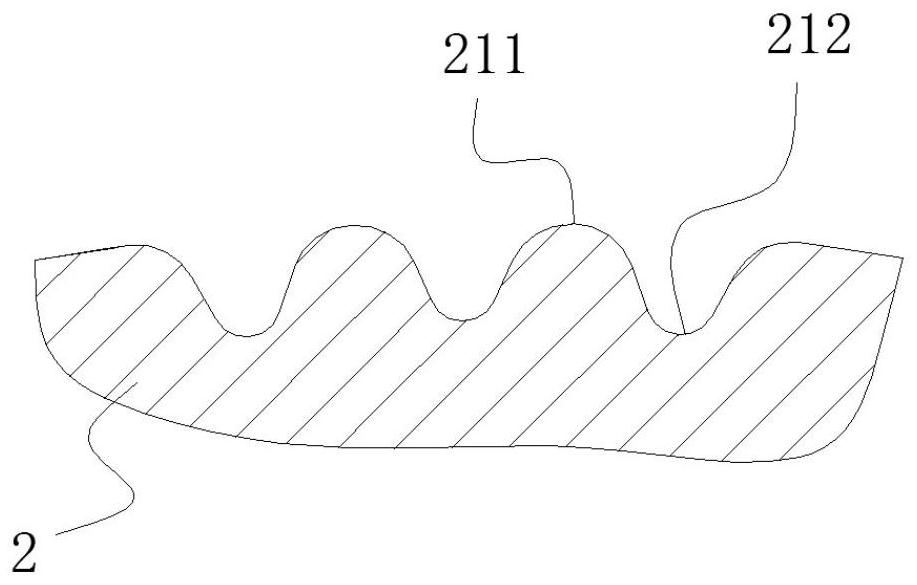

[0021] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach Figure 4 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

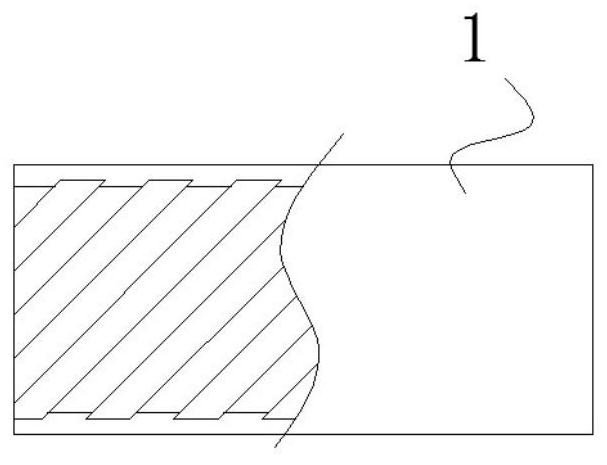

[0022] figure 1 It is a structural diagram of an embodiment of a low-micron thick-walled high-tooth internal thread copper pipe of the present invention. Such as figure 1 As shown, the low-mick heavy-walled high-tooth internal thread copper pipe provided in this embodiment includes: a tubular copper main body with an outer diameter of 7mm, which belongs to the field of 7mm copper pipes, and several strips are arranged on the inner wall of the main body. The threads arranged along the length of the main body, each thread is arranged in a helical line to form an internally threaded copper pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com