Multifunctional part assembling equipment

A technology for assembling equipment and parts, applied in the field of multi-functional precision parts assembly equipment, can solve the problems of high manufacturing cost and difficult manufacturing, and achieve the effect of ensuring stability, improving intelligence, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

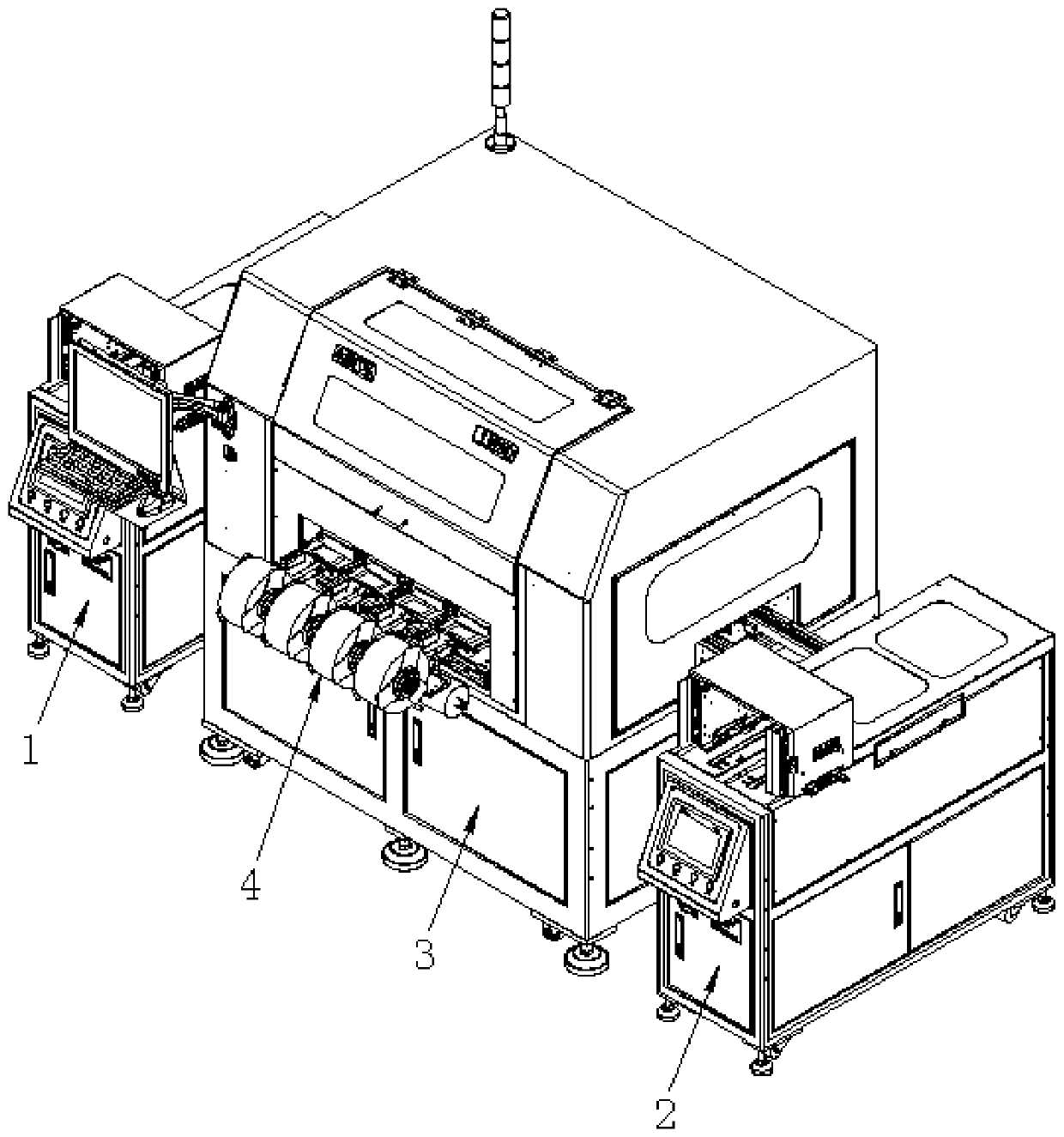

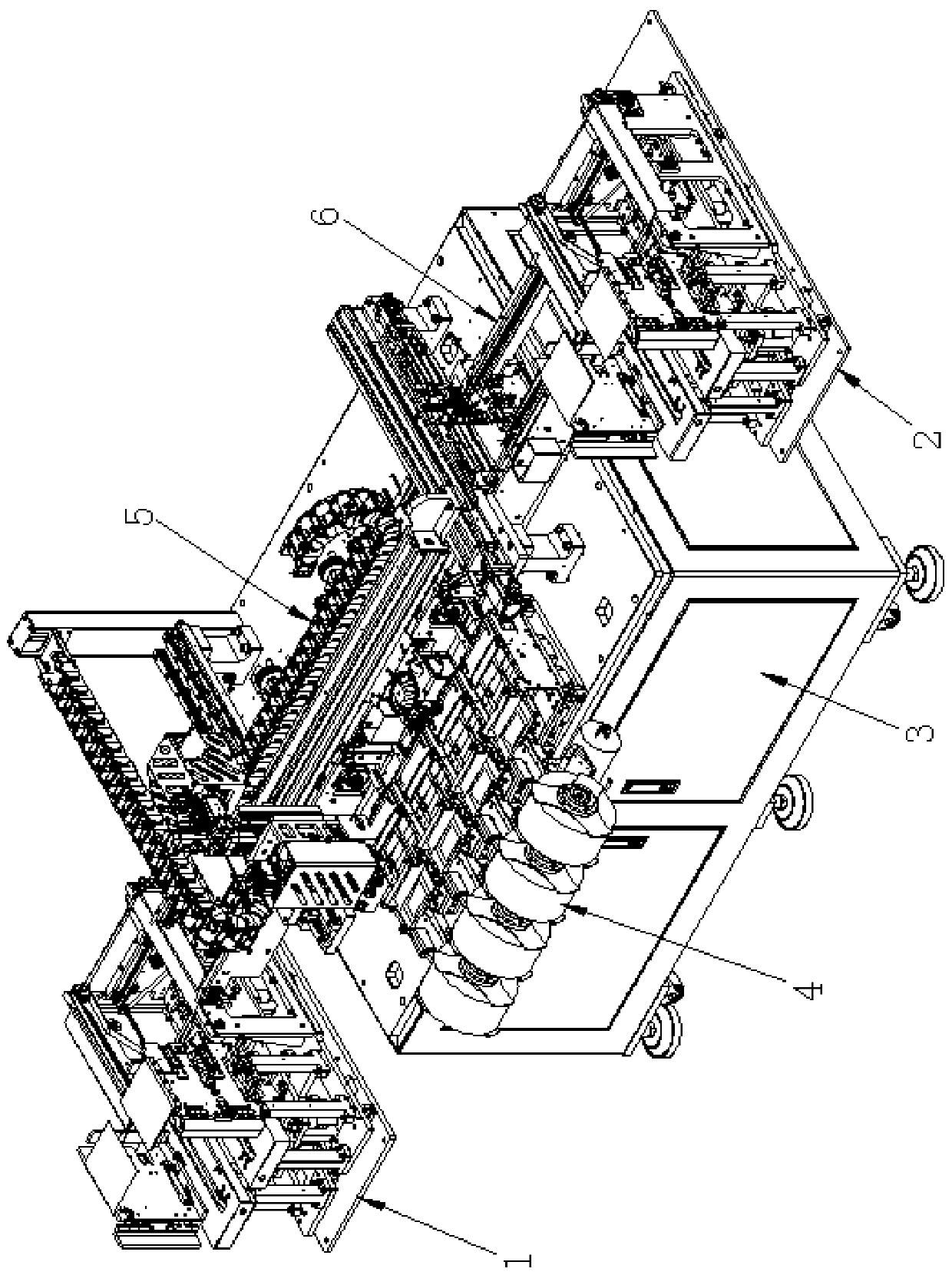

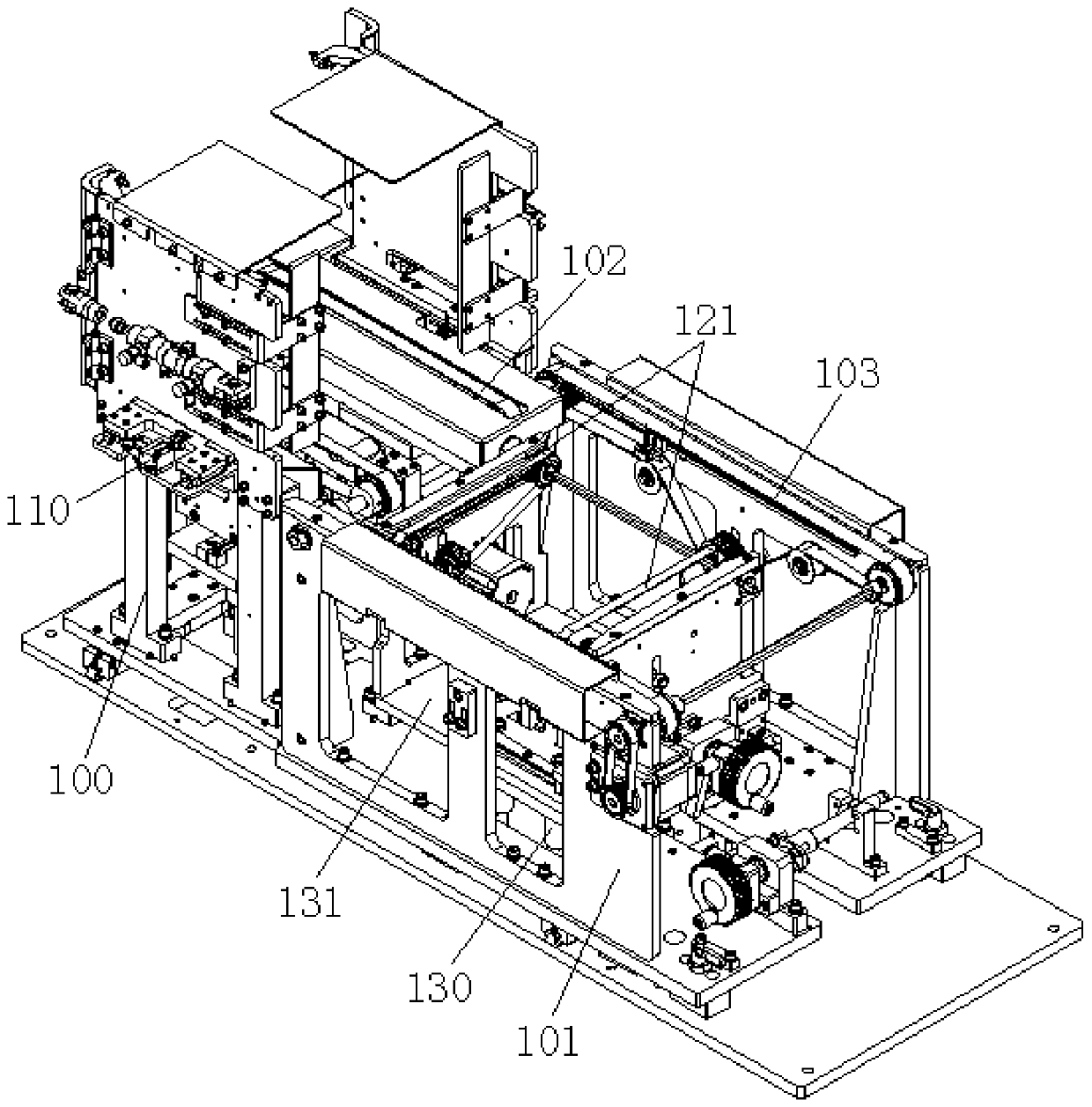

[0058] Please refer to the attached figure 1 And attached figure 2 As shown in FIG. 1 and 2 , respectively, are the three-dimensional structural schematic diagram and the internal structural schematic diagram of the multifunctional precision component assembly equipment of the present invention.

[0059] The multifunctional precision component assembly equipment is used to assemble the workpiece A bonded to the material roll R and the workpiece B placed on the material tray T, and the multifunctional precision component assembly equipment includes a feeding tray T The feeding device 1, the unloading device 2 for reclaiming the tray T, the chassis base 3, and the coil stripping device 4 and the material handling device 5 respectively installed above the chassis base 3, wherein the loading The device 1, the unloading device 2 and the chassis base 3 are arranged independently of each other. On the top side of the chassis base 3, a conveying flow line 6 for conveying the tray T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com