Antifouling and antibacterial ceramic glaze and preparation method thereof

An antibacterial ceramic and glaze technology, applied in the field of ceramic glaze, can solve the problems of ceramic surface pollution, difficult to remove, affecting cleaning and aesthetics, etc., and achieve the effects of low production cost, continuous antibacterial, and good stain resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

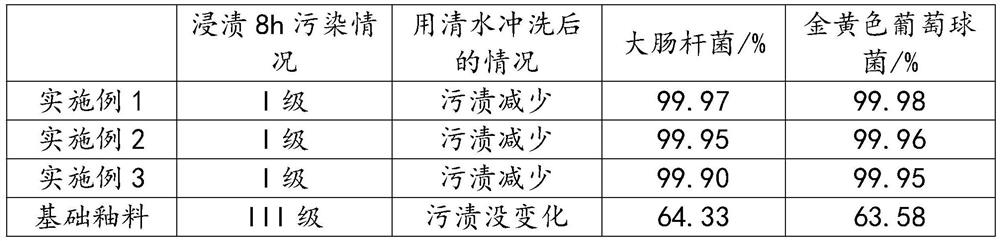

Examples

preparation example Construction

[0052] The preparation method of described antifouling and antibacterial ceramic glaze comprises the steps:

[0053] Step 1. Take calcium oxide, calcium carbonate, and aluminum hydroxide according to parts by weight, and fully mix them in a mixer:

[0054] Step 2. Put the phosphoric acid aqueous solution in a water bath at 55°C. When the temperature rises above 50°C, start stirring at a constant speed of 80r / min. Slowly add the uniformly mixed powder in step 1 to the phosphoric acid aqueous solution, and keep stirring at a constant speed while feeding. ;

[0055] Step 3. After adding the materials, continue to stir for 30 minutes, then naturally cool to 25-35 ° C, put it into a ball mill, add an aqueous solution of yttrium nitrate to the ball mill, and ball mill to obtain the first mixture;

[0056] Step 4, adding the first mixture, basic glaze slurry, antibacterial agent, dispersant and nano-zinc oxide into the ball mill for rapid ball milling for 20 minutes, and passing the...

Embodiment 1

[0060] The antifouling and antibacterial ceramic glaze is made of the following raw materials in parts by weight: 50 parts of basic glaze slurry, 7 parts of calcium oxide, 3 parts of calcium carbonate, 4 parts of aluminum hydroxide, 4 parts of antibacterial agent, 5 parts of nano-zinc oxide, six 2 parts of sodium metaphosphate, 8 parts of 35% phosphoric acid aqueous solution, 2 parts of 6% yttrium nitrate aqueous solution;

[0061] The preparation method of described antifouling and antibacterial ceramic glaze comprises the steps:

[0062] Step 1. Take calcium oxide, calcium carbonate, and aluminum hydroxide according to parts by weight, and fully mix them in a mixer:

[0063] Step 2. Put the phosphoric acid aqueous solution in a water bath at 55°C. When the temperature rises above 50°C, start stirring at a constant speed of 80r / min. Slowly add the uniformly mixed powder in step 1 to the phosphoric acid aqueous solution, and keep stirring at a constant speed while feeding. ; ...

Embodiment 2

[0068] The antifouling and antibacterial ceramic glaze is made of the following raw materials in parts by weight: 55 parts of basic glaze slurry, 8 parts of calcium oxide, 4 parts of calcium carbonate, 5 parts of aluminum hydroxide, 4.5 parts of antibacterial agent, 6 parts of nano-zinc oxide, six 2.5 parts of sodium metaphosphate, 9 parts of 38% phosphoric acid aqueous solution, 2.5 parts of 7% yttrium nitrate aqueous solution;

[0069] The preparation method of described antifouling and antibacterial ceramic glaze comprises the steps:

[0070] Step 1. Take calcium oxide, calcium carbonate, and aluminum hydroxide according to parts by weight, and fully mix them in a mixer:

[0071] Step 2. Put the phosphoric acid aqueous solution in a water bath at 55°C. When the temperature rises above 50°C, start stirring at a constant speed of 80r / min. Slowly add the uniformly mixed powder in step 1 to the phosphoric acid aqueous solution, and keep stirring at a constant speed while feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com