Method for preparing belite-sulfoaluminate cement by mechanochemical process at low temperature

A technology of belite sulfoaluminate and mechanochemical method, which is applied in the field of materials, can solve problems such as high energy consumption and complicated process, and achieve the effects of low energy consumption, lower calcination temperature, and lower chemical reaction barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing Belite sulfoaluminate cement by mechanochemical method at low temperature, comprising the steps of:

[0029] (1) Break silicon raw materials (blast furnace slag), aluminum raw materials (bauxite), calcareous raw materials (limestone) and industrial gypsum (desulfurized gypsum) into particles below 10mm, and then press 39.74:22.36:26.21: 12.25 mass ratio batching, ball milling (ball-to-material ratio 4:1, rotating speed 150r / min), after grinding for 24 hours (during every 3 hours, take out and crush the sinking material), to obtain raw meal;

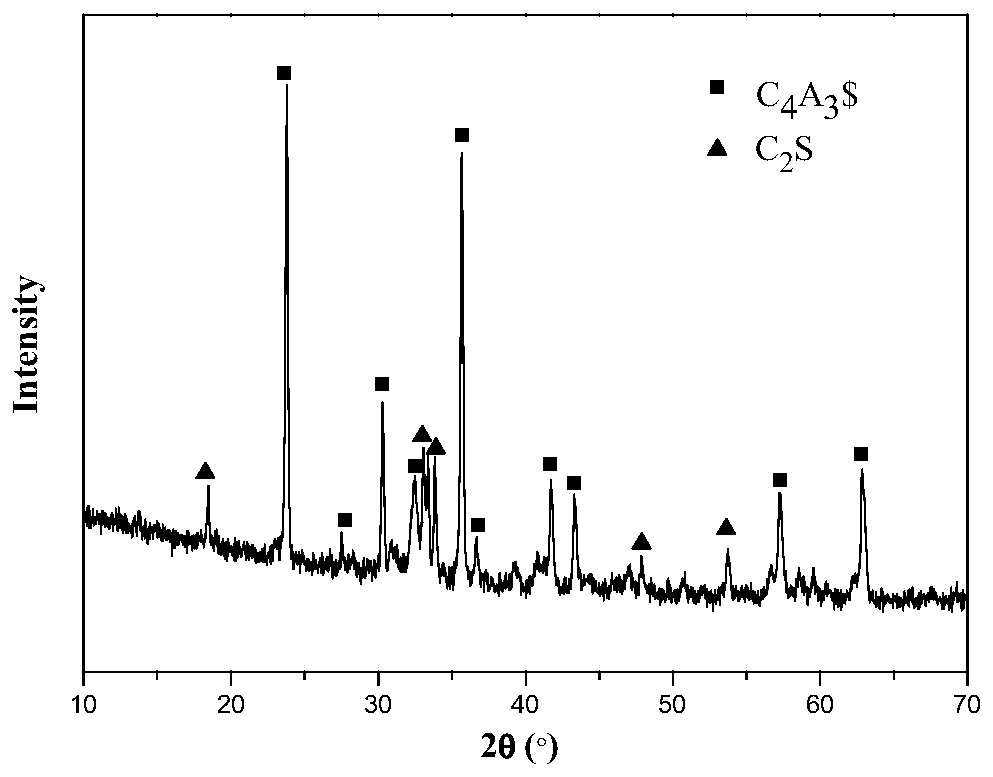

[0030] (2) Press the raw material into tablets at 3-5MPa, then calcined at 900°C, after 2 hours of heat preservation, take out and quench to obtain the clinker, and carry out XRD test on the clinker (such as figure 1 );

[0031] (3) Mix the clinker and dihydrate gypsum (the amount of dihydrate gypsum accounts for 5% of the clinker) and grind until it passes through a square hole sieve with an aperture of 80 ...

Embodiment 2

[0033] A method for preparing Belite sulfoaluminate cement by mechanochemical method at low temperature, comprising the steps of:

[0034] (1) Break silicon raw materials (steel slag), aluminum raw materials (bauxite), calcareous raw materials (limestone) and industrial gypsum (desulfurized gypsum) into particles below 10mm, and then press 29.05: 15.56: 42.46: 12.94 The mass ratio batching is carried out ball milling (ball-to-material ratio 5:1, rotating speed 250r / min), after grinding for 72h (period every 3h takes out and crushes sediment), obtains raw meal;

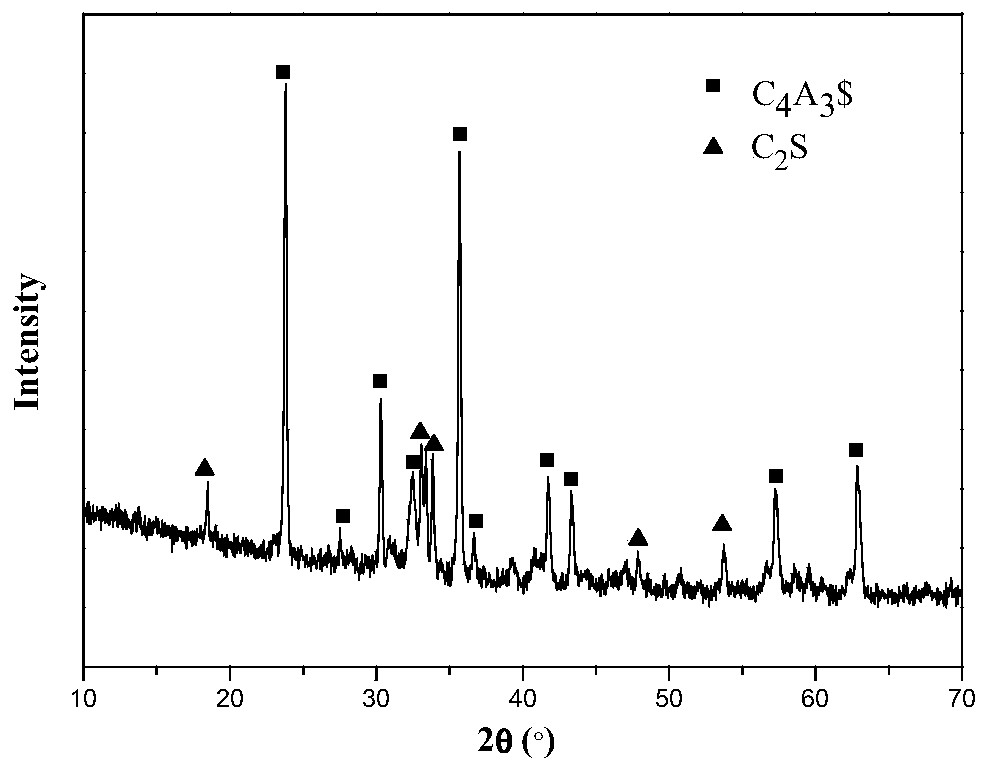

[0035] (2) Press the raw material into tablets at 3-5MPa, then calcined at 1000°C, after 1 hour of heat preservation, take out and quench to obtain the clinker, and carry out XRD test on the clinker (such as figure 2 );

[0036] (3) Mix the clinker and dihydrate gypsum (the amount of dihydrate gypsum accounts for 9% of the clinker), and grind until it passes through a square hole sieve with an aperture of 80 μm. The ...

Embodiment 3

[0038] A method for preparing Belite sulfoaluminate cement by mechanochemical method at low temperature, comprising the steps of:

[0039] (1) Break silicon raw materials (fly ash), aluminum raw materials (bauxite), calcareous raw materials (limestone) and industrial gypsum (desulfurized gypsum) into particles below 10mm, and then press 31.9:17.7:38.05 : 12.35 mass ratio batching, carry out ball milling (ball-to-material ratio 6:1, rotating speed 350r / min), after grinding 60h (period every 3h takes out and crushes sedimentation material), obtains raw meal;

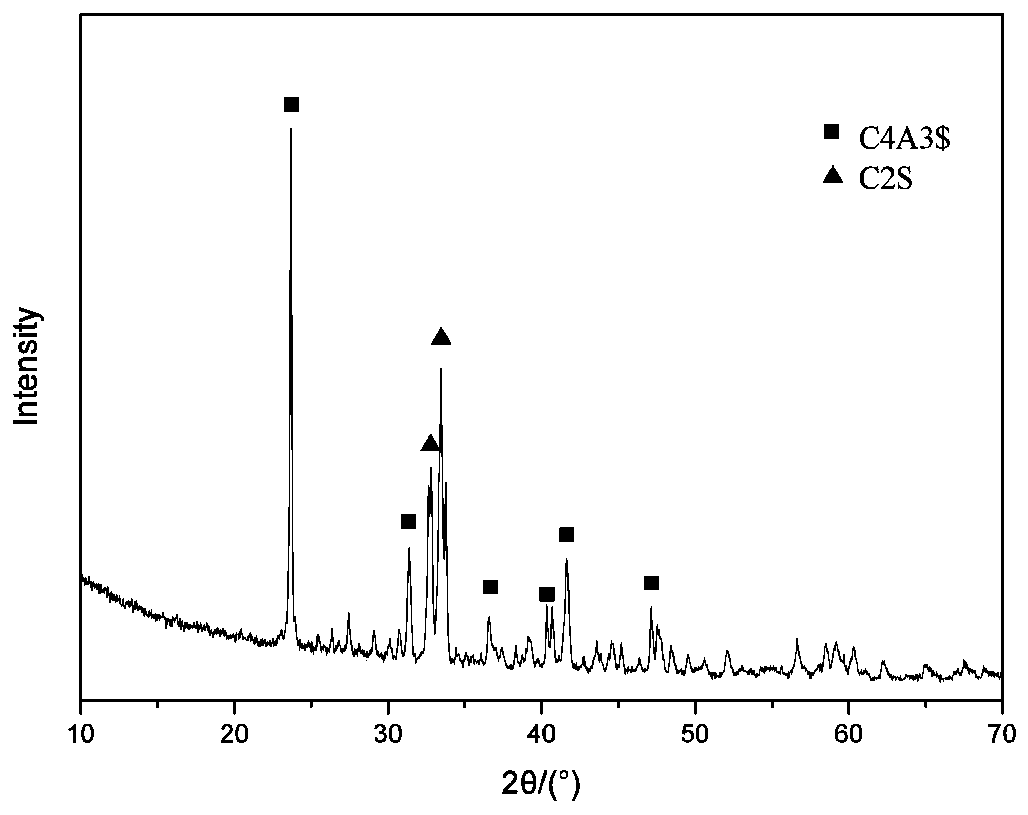

[0040] (2) Press the raw material into tablets at 3-5MPa, then calcined at 1100°C, after 2 hours of heat preservation, take out and quench to obtain the clinker, and carry out XRD test on the clinker (such as image 3 );

[0041] (3) Mix the clinker and dihydrate gypsum (the amount of dihydrate gypsum accounts for 13% of the clinker), and grind until it passes through a square hole sieve with an aperture of 80 μm. The sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com