High-water filling material for underground coal mine and preparation method and device of filling material

A technology for filling materials and preparation devices, which is applied in the field of materials used in underground coal mines. It can solve problems such as failure to take environmental protection measures, low filling strength, and polluted mine water, and achieve the effect of realizing solid waste recycling, low cost, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

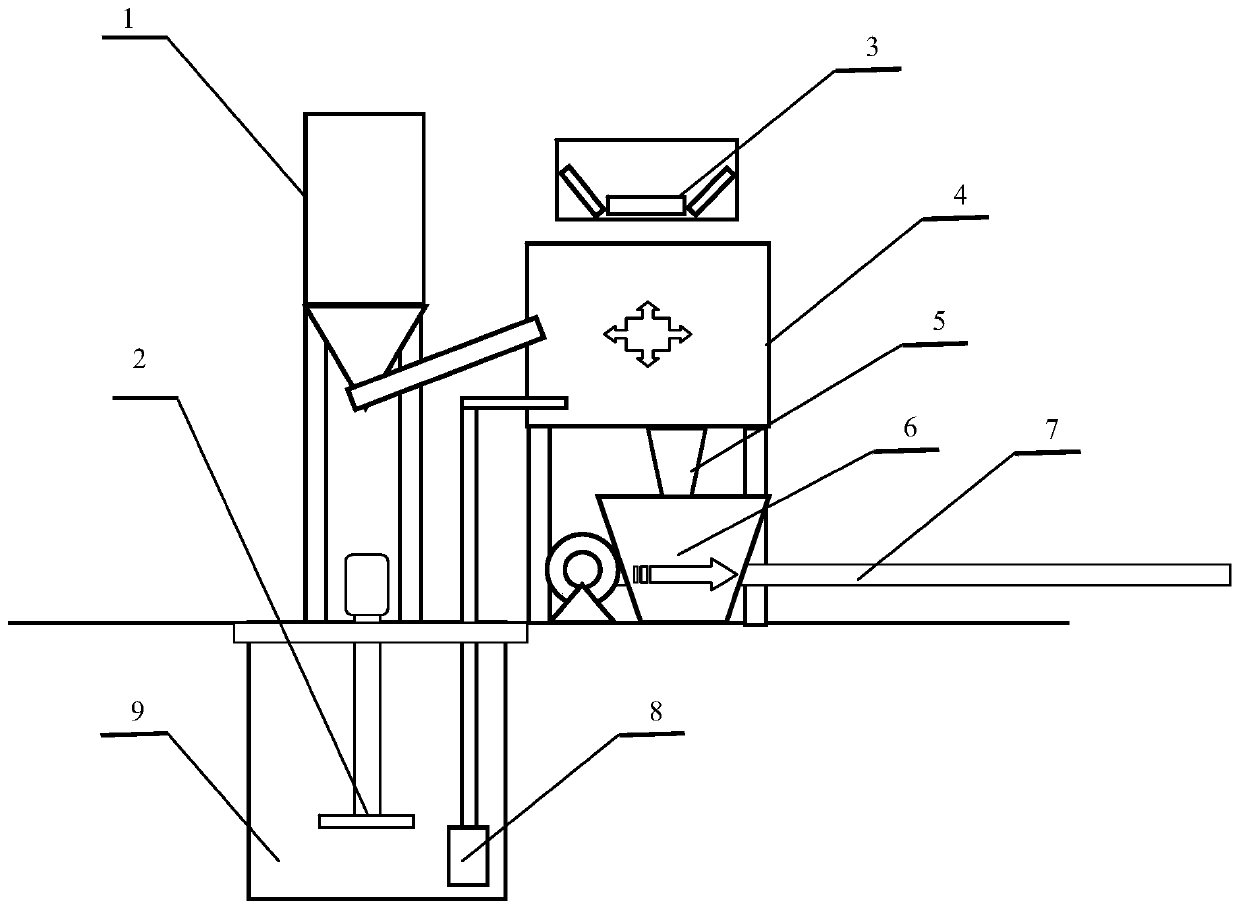

Image

Examples

Embodiment 1

[0036] Add 200 kg of high-calcium fly ash and 10 kg of admixture to 200 kg of water, stir evenly, and after standing for 8 hours, add 80 kg of cement and 600 kg of coal gasification slag, and mix evenly to obtain filling materials that can be used in underground coal mines.

[0037] It will be tested that the compressive strength of the material is 10Mpa, without cracking and fragmentation; the volume moisture content is 70%; the dimethyl blue adsorption rate is 2%.

Embodiment 2

[0039] Add 600 kg of high-calcium fly ash and 20 kg of admixture to 450 kg of water, stir evenly, and after standing for 24 hours, add 180 kg of cement and 750 kg of coal gasification slag, and mix well to obtain materials that can be used for filling coal mines.

[0040] The measured compressive strength of the material is 12Mpa, without cracking and fragmentation; the volume moisture content is 75%; the dimethyl blue adsorption rate is 3%.

Embodiment 3

[0042] Add 800 kg of high-calcium fly ash and 30 kg of admixture to 700 kg of water, stir evenly, and after standing for 48 hours, add 220 kg of cement and 1,200 kg of coal gasification slag, and mix evenly to obtain materials that can be used for filling coal mines.

[0043] The measured compressive strength of the material is 11Mpa, without cracking and fragmentation; the volume moisture content is 77%; the dimethyl blue adsorption rate is 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com