Green preparation method of aluminum acetylacetonate

A technology of aluminum acetylacetonate and aluminum acetonate, which is applied in the preparation of aldehyde/ketone chelate compound, organic chemistry, etc., can solve the problems of pollution and incomplete reaction of aluminum acetylacetonate, and achieve the effect of reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

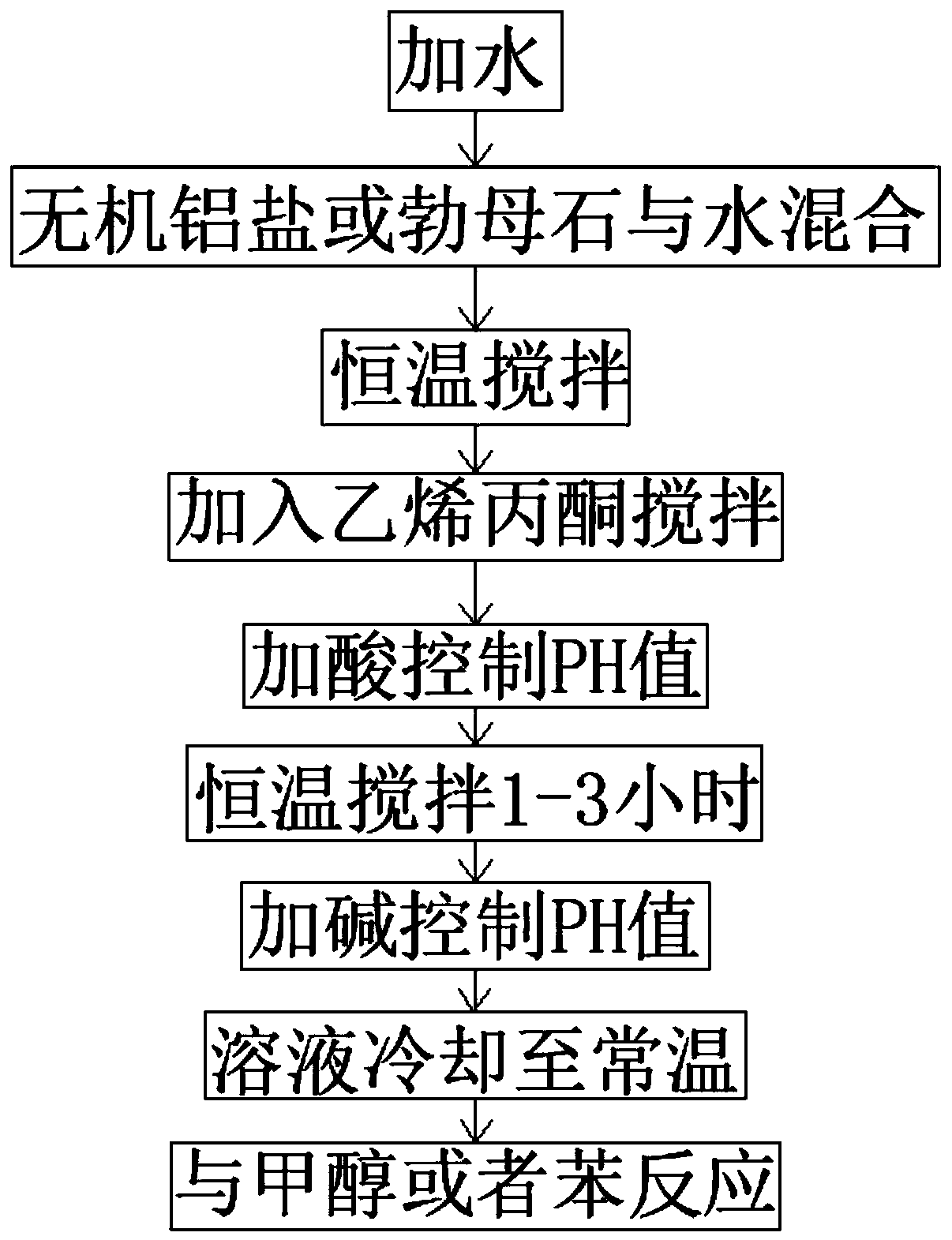

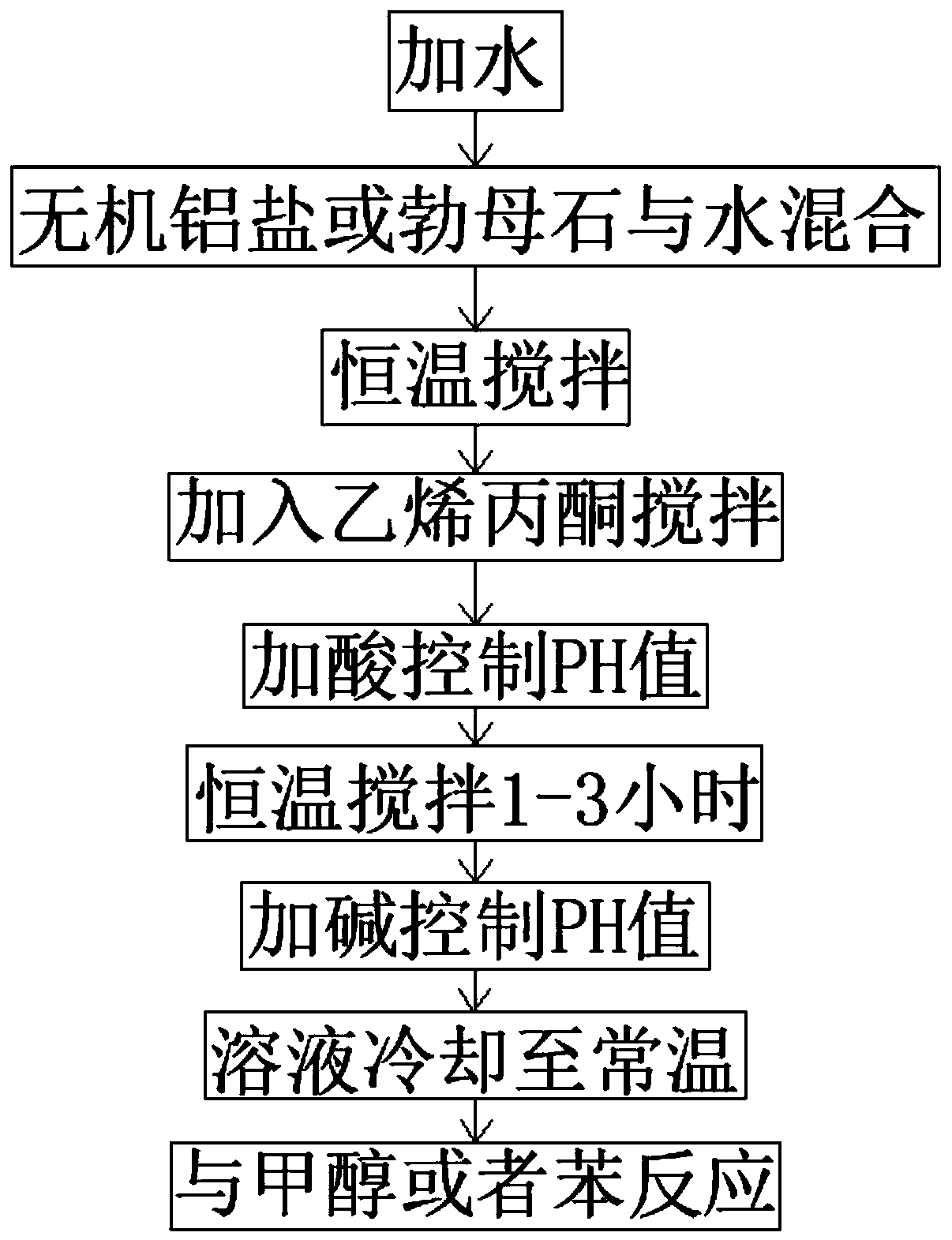

Method used

Image

Examples

Embodiment 1

[0025] The green preparation method of this aluminum acetylacetonate is as follows:

[0026] Step 1: Pour 100kg of water into the reactor;

[0027] Step 2: Add 30kg of inorganic aluminum salt while stirring the water, so that the inorganic aluminum salt is evenly mixed with water;

[0028] Step 3: heating the solution to 60°C while stirring the solution;

[0029] Step 4: Add 50kg of acetylacetone at a constant temperature and stir evenly;

[0030] Step 5: During the stirring process, add acidic substances to the solution so that the pH value of the solution is between 1.0-4.0;

[0031] Step 6: Stir the solution in the reactor at 60°C for 1 hour;

[0032] Step 7: During the stirring process, add alkaline substances to the solution so that the pH value of the solution is between 6.0-8.0;

[0033] Step 8: While stirring, add 40kg of isopropanol and 35kg of acetone and stir at a constant speed;

[0034] Step 9: After the reaction, the temperature of the solution in the reacto...

Embodiment 2

[0038] The green preparation method of this aluminum acetylacetonate is as follows:

[0039] Step 1: Pour 150kg of water into the reactor;

[0040] Step 2: Add 35kg of inorganic aluminum salt while stirring the water, so that the inorganic aluminum salt is evenly mixed with water;

[0041] Step 3: heating the solution to 75°C while stirring the solution;

[0042] Step 4: Add 75kg of acetylacetone at a constant temperature and stir evenly;

[0043] Step 5: During the stirring process, add acidic substances to the solution so that the pH value of the solution is between 1.0-4.0;

[0044] Step 6: Stir the solution in the reactor at 75°C for 2 hours;

[0045] Step 7: During the stirring process, add alkaline substances to the solution so that the pH value of the solution is between 6.0-8.0;

[0046] Step 8: While stirring, add 55kg of isopropanol and 45kg of acetone and stir at a constant speed;

[0047] Step 9: After the reaction, the temperature of the solution in the react...

Embodiment 3

[0051] The green preparation method of this aluminum acetylacetonate is as follows:

[0052] Step 1: Pour 200kg of water into the reactor;

[0053] Step 2: Add 40kg of inorganic aluminum salt while stirring the water, so that the inorganic aluminum salt is evenly mixed with water;

[0054] Step 3: heating the solution to 90°C while stirring the solution;

[0055] Step 4: Add 100kg of acetylacetone at a constant temperature and stir evenly;

[0056] Step 5: During the stirring process, add acidic substances to the solution so that the pH value of the solution is between 1.0-4.0;

[0057] Step 6: Stir the solution in the reactor at 90°C for 3 hours;

[0058] Step 7: During the stirring process, add alkaline substances to the solution so that the pH value of the solution is between 6.0-8.0;

[0059] Step 8: While stirring, add 75kg of isopropanol and 60kg of acetone and stir at a constant speed;

[0060] Step 9: After the reaction, the temperature of the solution in the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com