Wear-resistant insulating material covering bare overhead conductor and preparation method and application thereof

An insulating material and coating technology, applied in insulators, coatings, electrical components, etc., can solve problems such as low hardness, poor wear resistance, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

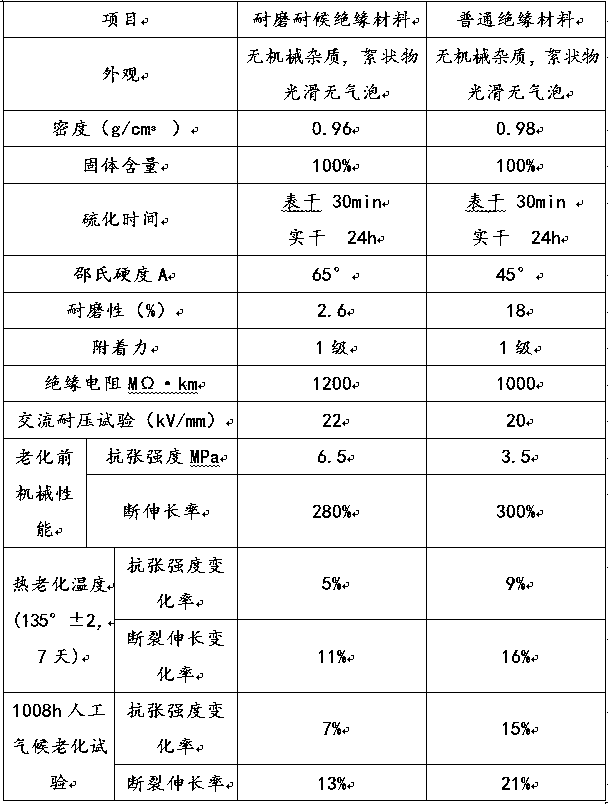

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A wear-resistant insulating material coated on overhead bare wires, comprising the following ingredients in parts by weight:

[0069] Hydroxypolyphenylmethylsiloxane 30 parts,

[0070] 38 parts of hydroxyl-terminated polydimethylsiloxane,

[0071] Hydrophobic nano fumed silica 12 parts,

[0072] Hydrophobic microsilica powder 28 parts,

[0073] Hydrophobic silicon carbide 2 parts,

[0074] 6 parts of hollow glass microspheres,

[0075] 1.5 parts of pigment,

[0076] 7 parts of deketoxime type cross-linking agent,

[0077] Catalyst 3 parts.

[0078] The hydroxypolyphenylmethylsiloxane consists of 30 parts of 2,4,6-trimethyl-2,4,6-triphenylcyclotrisiloxane, 70 parts of octamethylcyclotetrasiloxane, Prepared from 0.2 parts of deionized water and 0.5 parts of tetramethylammonium hydroxide silicon alkoxide.

[0079] The preparation method of the wear-resistant insulating material coated on the bare overhead wire includes the following steps:

[0080] First, prepare ...

Embodiment 2

[0086] A wear-resistant insulating material coated on overhead bare wires, comprising the following ingredients in parts by weight:

[0087] Hydroxypolyphenylmethylsiloxane 20 parts,

[0088] 50 parts of hydroxyl-terminated polydimethylsiloxane,

[0089] Hydrophobic nano fumed silica 8 parts,

[0090] 32 parts of hydrophobic silica powder,

[0091] Hydrophobic silicon carbide 1 part,

[0092] 10 parts of hollow glass microspheres,

[0093] 1 part paint,

[0094] 6 parts of deketoxime type cross-linking agent,

[0095] Catalyst 2 parts.

[0096] The hydroxypolyphenylmethylsiloxane consists of 40 parts of 2,4,6-trimethyl-2,4,6-triphenylcyclotrisiloxane, 80 parts of octamethylcyclotetrasiloxane, Prepared from 0.5 parts of deionized water and 0.8 parts of tetramethylammonium hydroxide silicon alkoxide.

[0097] The preparation method of the wear-resistant insulating material coated on the bare overhead wire includes the following steps:

[0098] First, prepare the hydroxy...

Embodiment 3

[0104] A wear-resistant insulating material coated on overhead bare wires, comprising the following ingredients in parts by weight:

[0105] Hydroxypolyphenylmethylsiloxane 25 parts,

[0106] 42 parts of hydroxyl-terminated polydimethylsiloxane,

[0107] Hydrophobic nano fumed silica 16 parts,

[0108] Hydrophobic microsilica powder 40 parts,

[0109] Hydrophobic silicon carbide 5 parts,

[0110] 8 parts of hollow glass microspheres,

[0111] 2 parts of paint,

[0112] 10 parts of deketoxime type cross-linking agent,

[0113] Catalyst 2.5 parts.

[0114] The hydroxypolyphenylmethylsiloxane consists of 28 parts of 2,4,6-trimethyl-2,4,6-triphenylcyclotrisiloxane, 90 parts of octamethylcyclotetrasiloxane, Prepared from 0.05 parts of deionized water and 0.6 parts of tetramethylammonium hydroxide silicon alkoxide.

[0115] The preparation method of the wear-resistant insulating material coated on the bare overhead wire includes the following steps:

[0116] First, prepare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com