Combined condensate liquid pump

A condensate and composite technology, applied in the direction of non-variable pumps, pumps, pump control, etc., can solve the problems of condensate pump cooling capacity to be improved, time-consuming, laborious, mechanical corrosion, etc., to achieve easy balance of local air pressure, condensation process Smooth and reduce the effect of water velocity difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

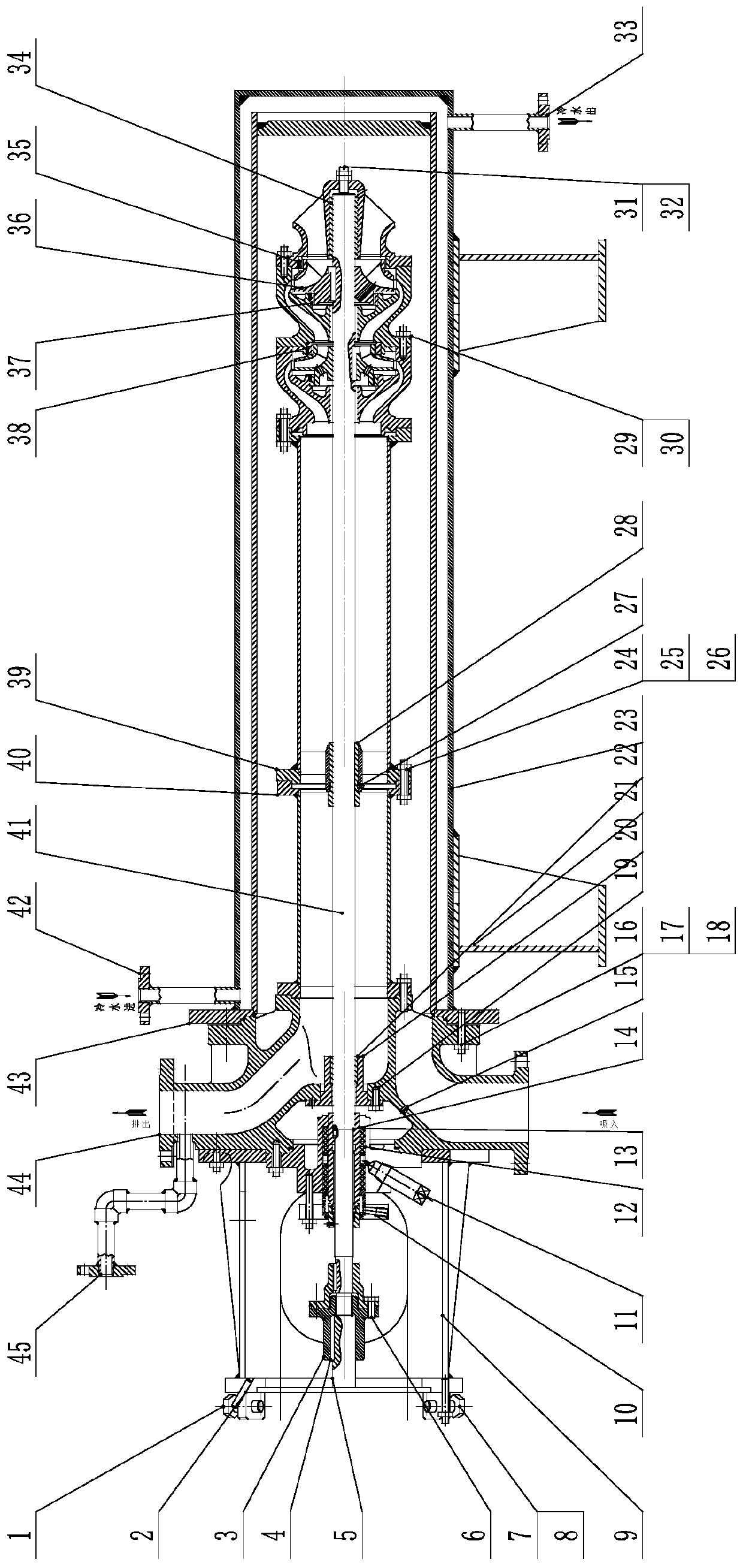

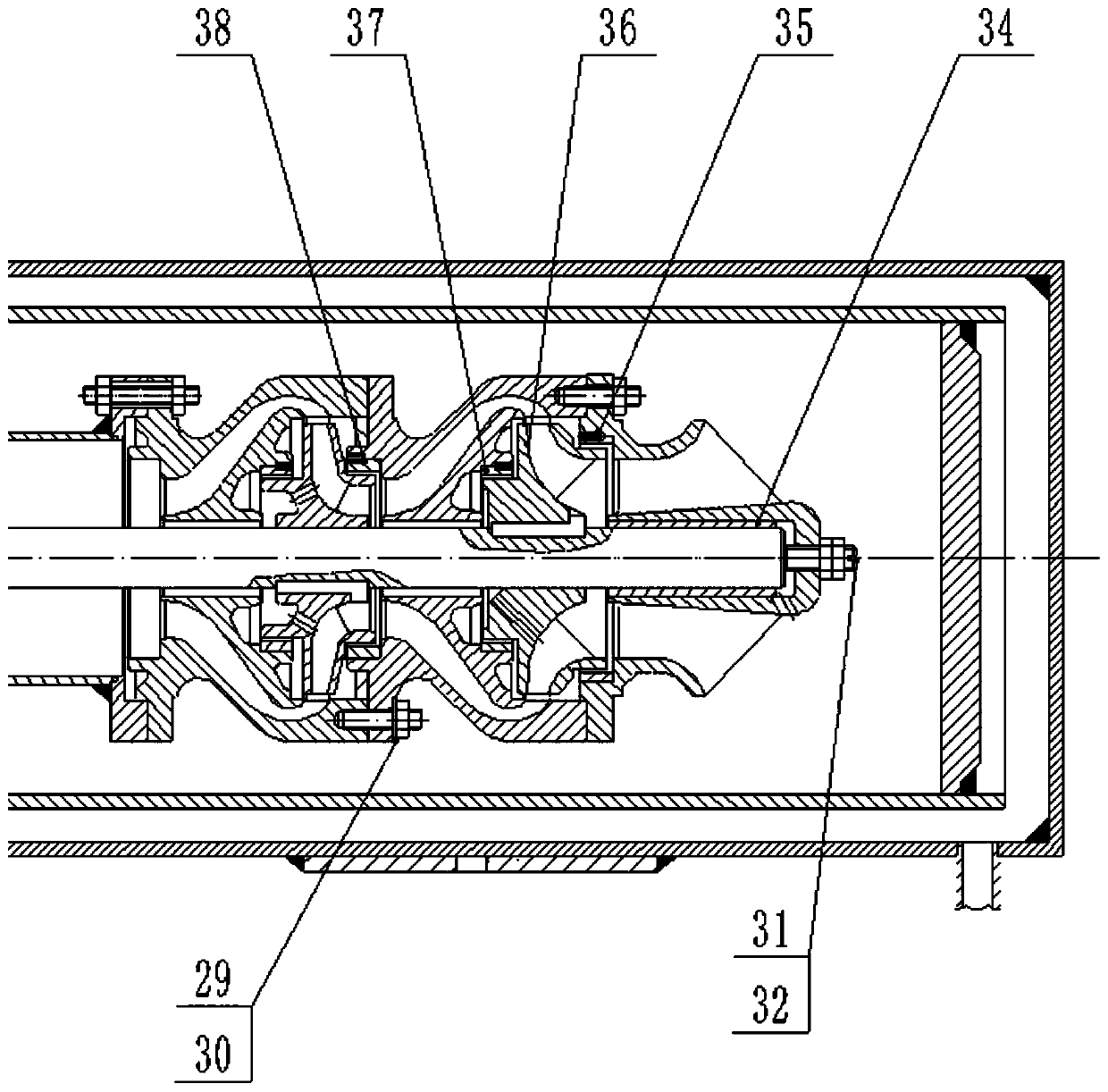

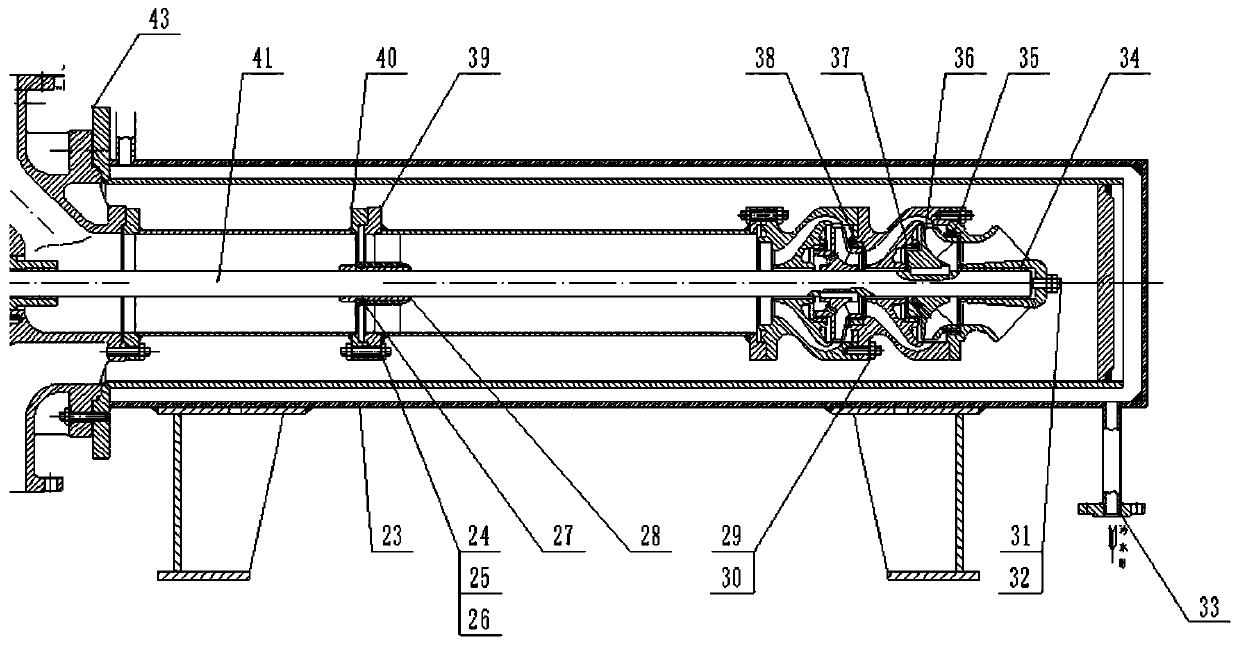

[0026] like Figure 1-Figure 4 As shown, the composite condensate pump of the present invention includes a motor shaft 5, a motor bracket 9, a base 21, a pipe shell 23, a coolant outlet pipe 33, a secondary impeller 36, a bearing joint assembly 39, and a first joint assembly Part 40, pump shaft 41, coolant inlet pipe 42, casing 43, pump outlet cover 44, and second connection assembly 45.

[0027] The motor is fixed to the motor bracket 9 through the outer hexagonal screw 1, the first bolt 8, and the first nut 7; the motor shaft is connected to the pump shaft 41 through the half coupling 3 at the motor end and the coupling key 4 at the driving end; the pump shaft 41 Installed in the pump casing, the connection between the pump casing and the pump shaft 41 is installed with the bearing 20, the sliding bearing sleeve 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com