Solarenergy heat absorber with built-in lens capable of moving in reciprocating mode in axial direction

A solar heat absorber, reciprocating motion technology, applied in solar collectors, solar collectors using working fluid, components of solar collectors, etc., can solve problems such as easy high temperature creep, and achieve extended use life, preventing excessive temperature gradient, preventing high temperature creep and excessive thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

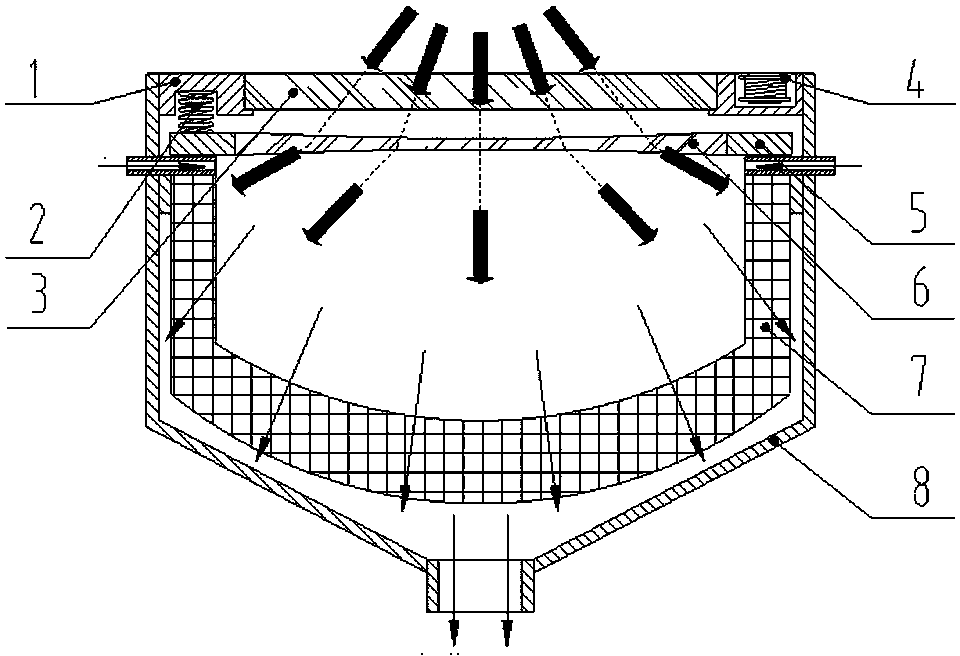

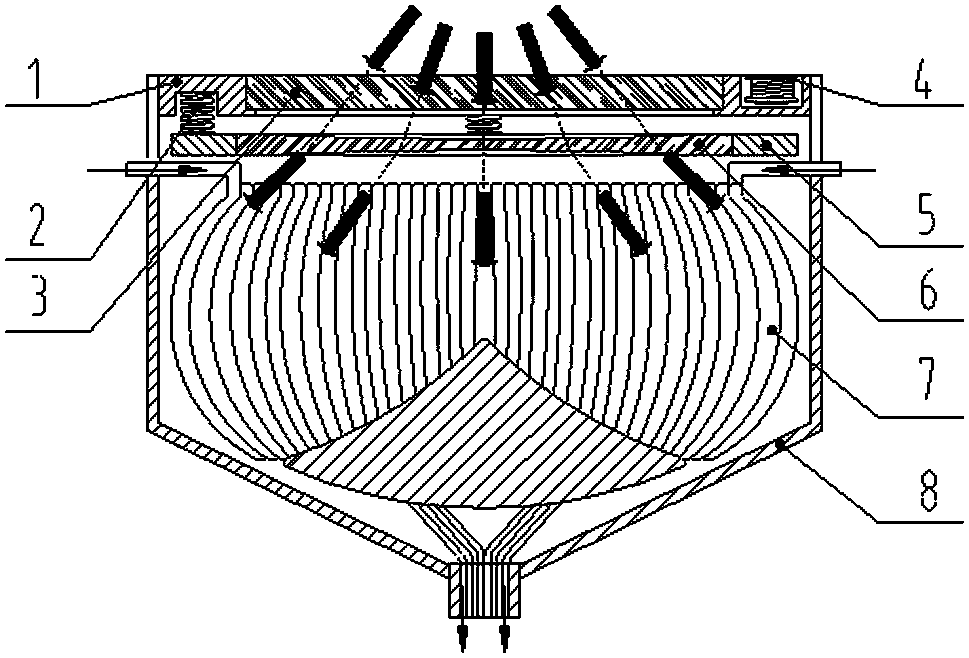

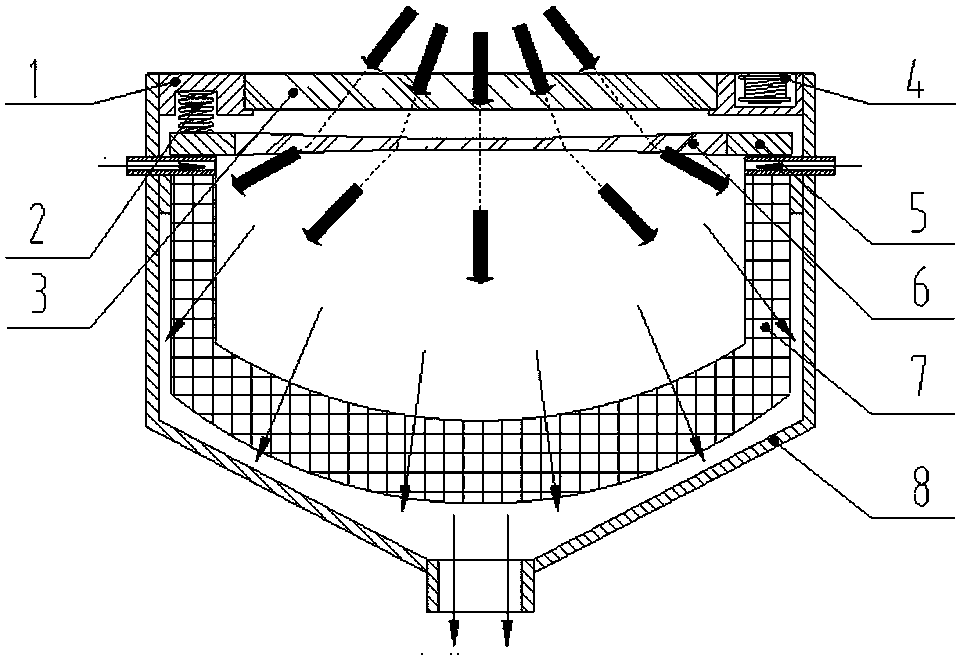

[0016] Such as figure 1 , 2 As shown, the present invention includes an end cover 1 , a quartz glass window 3 , a pulse electromagnet 4 , a lens mounting frame 5 , a non-planar lens 6 , a heat absorbing device 7 and a heat absorber housing 8 . The heat absorbing device 7 is installed in the heat absorber shell 8; the quartz glass window 3 is fixedly installed at the sunlight inlet of the heat absorber shell 8 through the end cover 1. The lens mounting frame 5 is a ring structure, the lens mounting frame 5 is made of magnetic material, and the central hole of the lens mounting frame 5 is provided with a non-planar lens 6; the non-planar lens 6 is a concave lens, a convex lens or a variable parameter non-planar lens.

[0017] The lens mounting frame 5 is made of cast iron and is located in the heat absorber shell 8. It is connected to the end cover 1 through several s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com