Visual system for workshop production process based on virtual sensor and building method

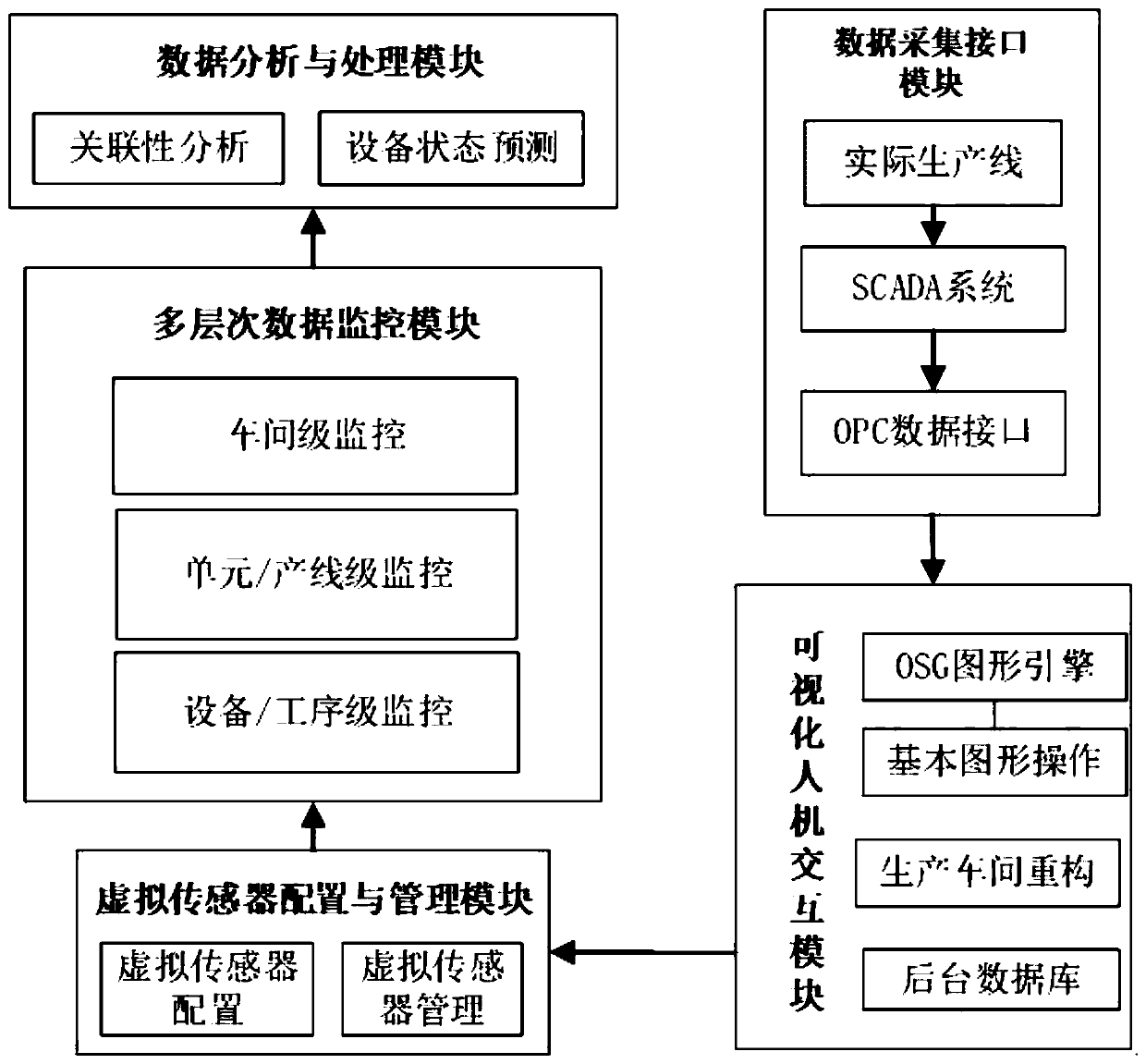

A virtual sensor and production process technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of unified configuration and transmission of production data, high requirements for hardware equipment, and high cost, so as to achieve good versatility and improve data quality. The effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The following is a visual control of a discrete production workshop

[0050] The structural parts production workshop mainly produces aviation structural parts. The workshop includes several functional areas such as a three-dimensional storage area, a five-axis CNC milling processing area, and a flexible processing unit. The equipment specifically includes a five-axis linkage data machine tool, a machining center, a three-dimensional warehouse, and AGV. , six-degree-of-freedom manipulator, buffer station, etc.; it has the characteristics of many varieties and small batches, difficult processing, and high processing quality requirements. The workshop is in urgent need of visual control of the status of processing equipment and workshop operation to ensure processing quality and on-time delivery of products.

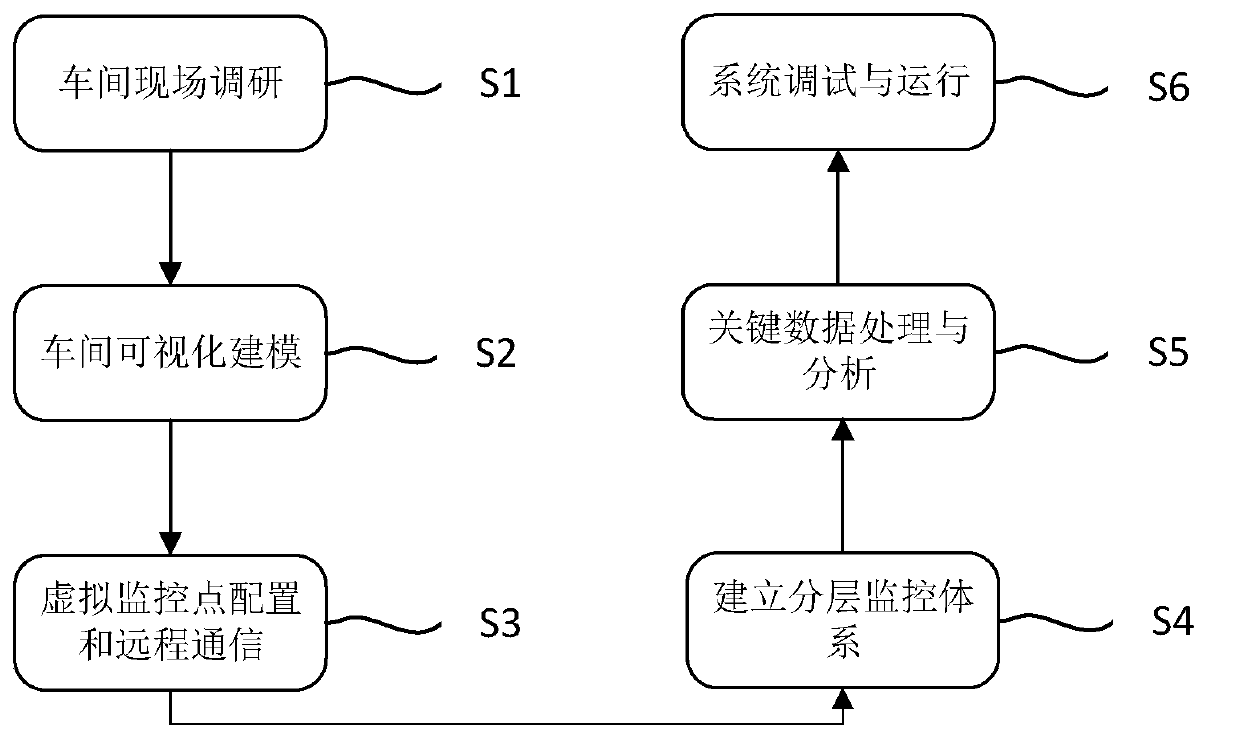

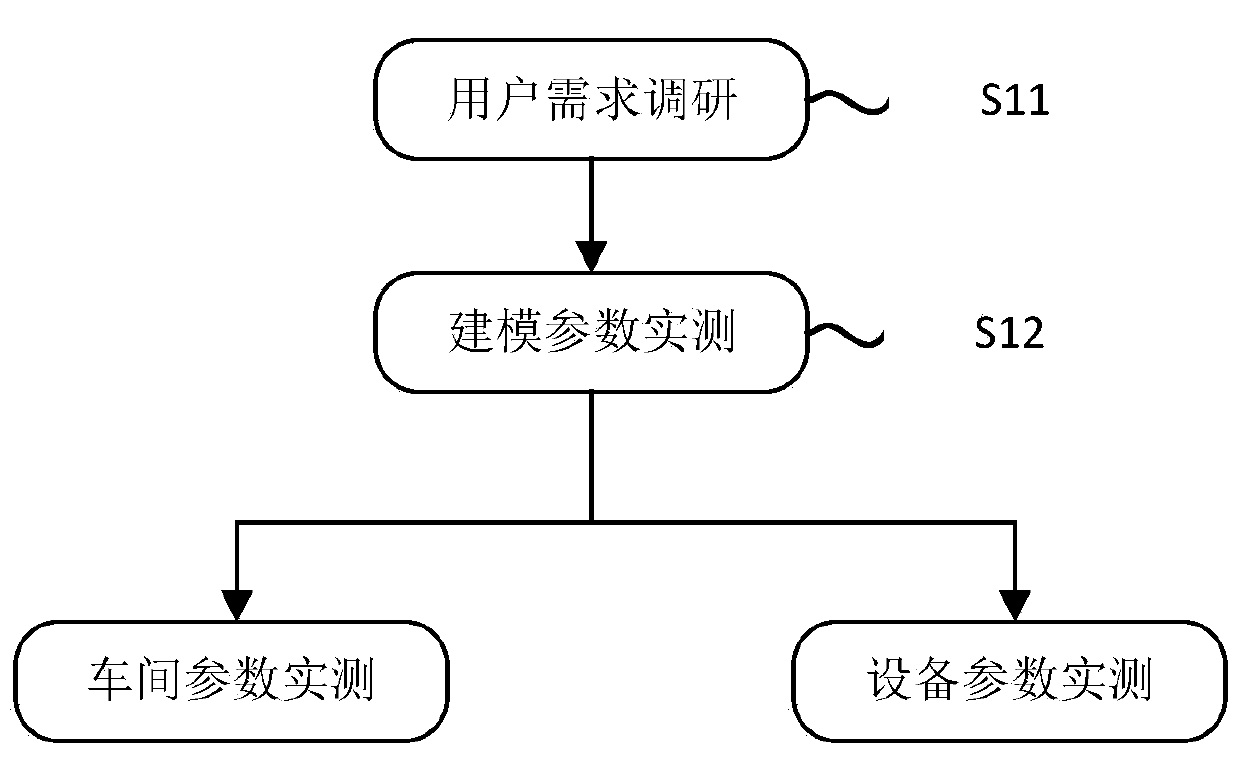

[0051] Such as image 3 As shown, first conduct research on the specific needs of the workshop, including surveying and mapping the layout of the workshop and the ...

Embodiment 2

[0077] The system of the present invention is used to carry out visual management and control on a process-type lithium battery production workshop. The lithium battery production workshop is mainly responsible for the batch production of cathode materials for lithium-ion batteries. It has complete equipment and devices, including: batching devices, mixers, pulverizers, high-temperature kilns, dust collectors, etc. At the same time, the production workshop has 5 production lines, and each production line can be divided into several processes such as batching, mixing, filling, roasting, and unloading according to the process. The workshop has the characteristics of many types of production equipment, close connection between each equipment, and poor adaptability to production equipment failure. The workshop put forward requirements for the monitoring system, such as visual control, real-time communication, status warning, and the establishment of a multi-level monitoring syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com