Wafer surface defect mode detection and analysis method

A defect mode and analysis method technology, which is applied in character and pattern recognition, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problem of manual extraction of wafer defect mode diagrams, inability to analyze the cause of defect modes, and low classification accuracy, etc. problem, achieve the effect of reducing labor cost, high labor intensity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The method will be described in detail below in conjunction with the accompanying drawings and examples.

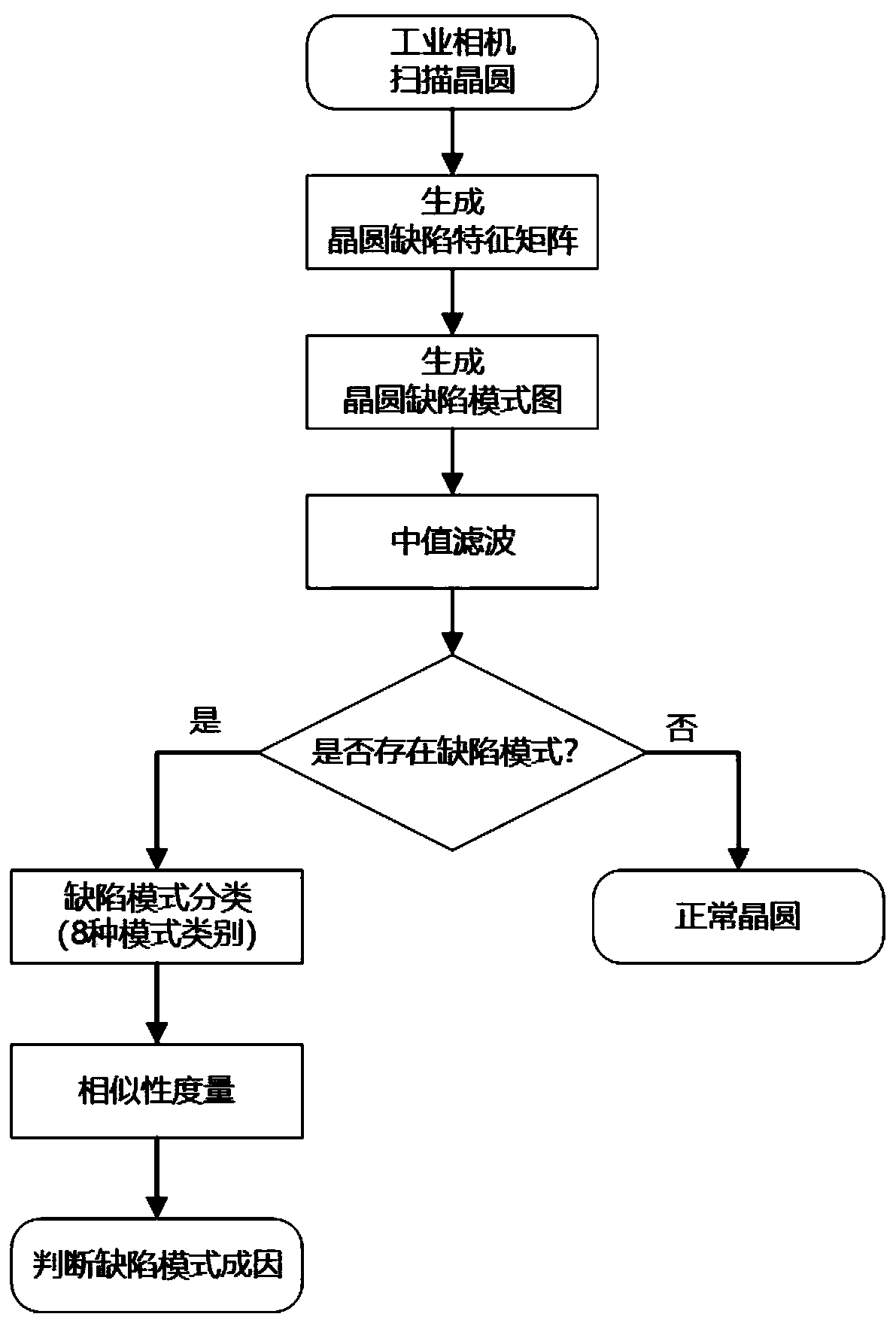

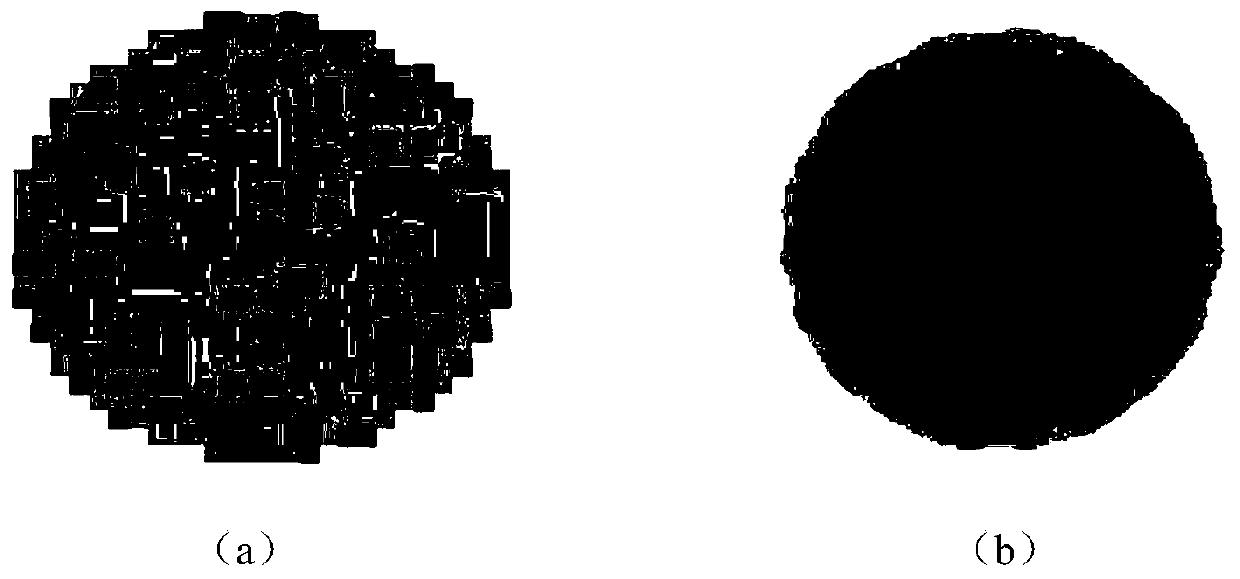

[0046] figure 1 is the flow chart of wafer surface defect pattern detection and analysis method. Firstly, the crystal grains on the wafer are scanned to generate a wafer defect pattern map, which is input into the trained wafer defect pattern detection model after image preprocessing. If there is a defect mode, it is a normal wafer, and the inspection process is exited; if there is a defect mode, it is input into the classification model to determine the specific defect mode type. Finally, according to the proposed similarity measurement algorithm, the most similar sample to the sample to be tested is found in the database, and the root cause of the defect of the sample to be tested is inferred by analyzing the cause of the defect pattern of the similar sample. Specific steps are as follows:

[0047] 1. Acquisition of Wafer Image

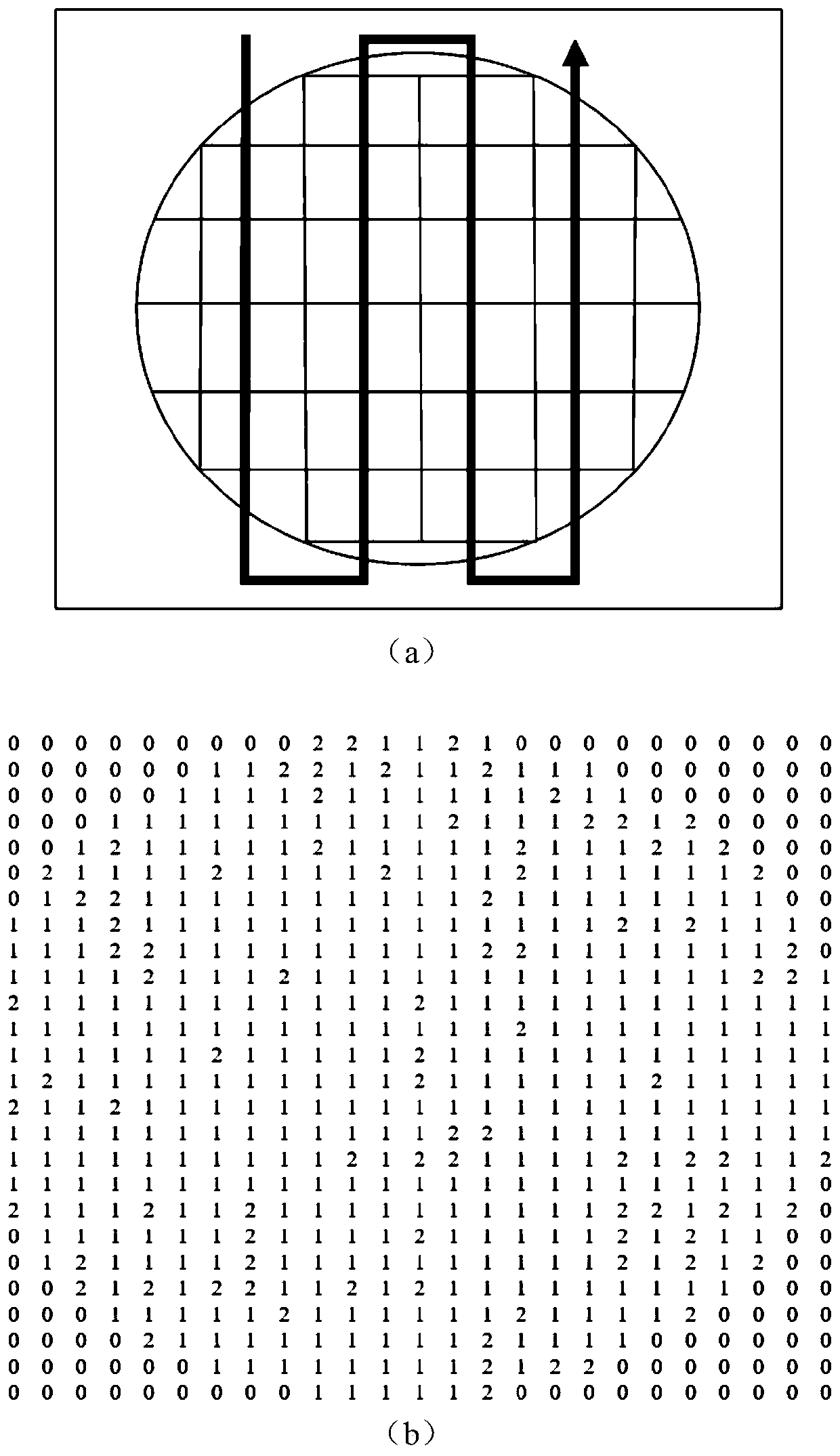

[0048] The image acquisition e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com