Material automatic identification and simulation assembly system

An assembly system and material identification technology, applied in design optimization/simulation, logistics, sustainable waste treatment, etc., can solve problems such as low recycling efficiency, impact on construction period, and inconsistent management of serial numbers, so as to avoid pre-assembly process and shorten Impact on construction period, intuitive and accurate data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

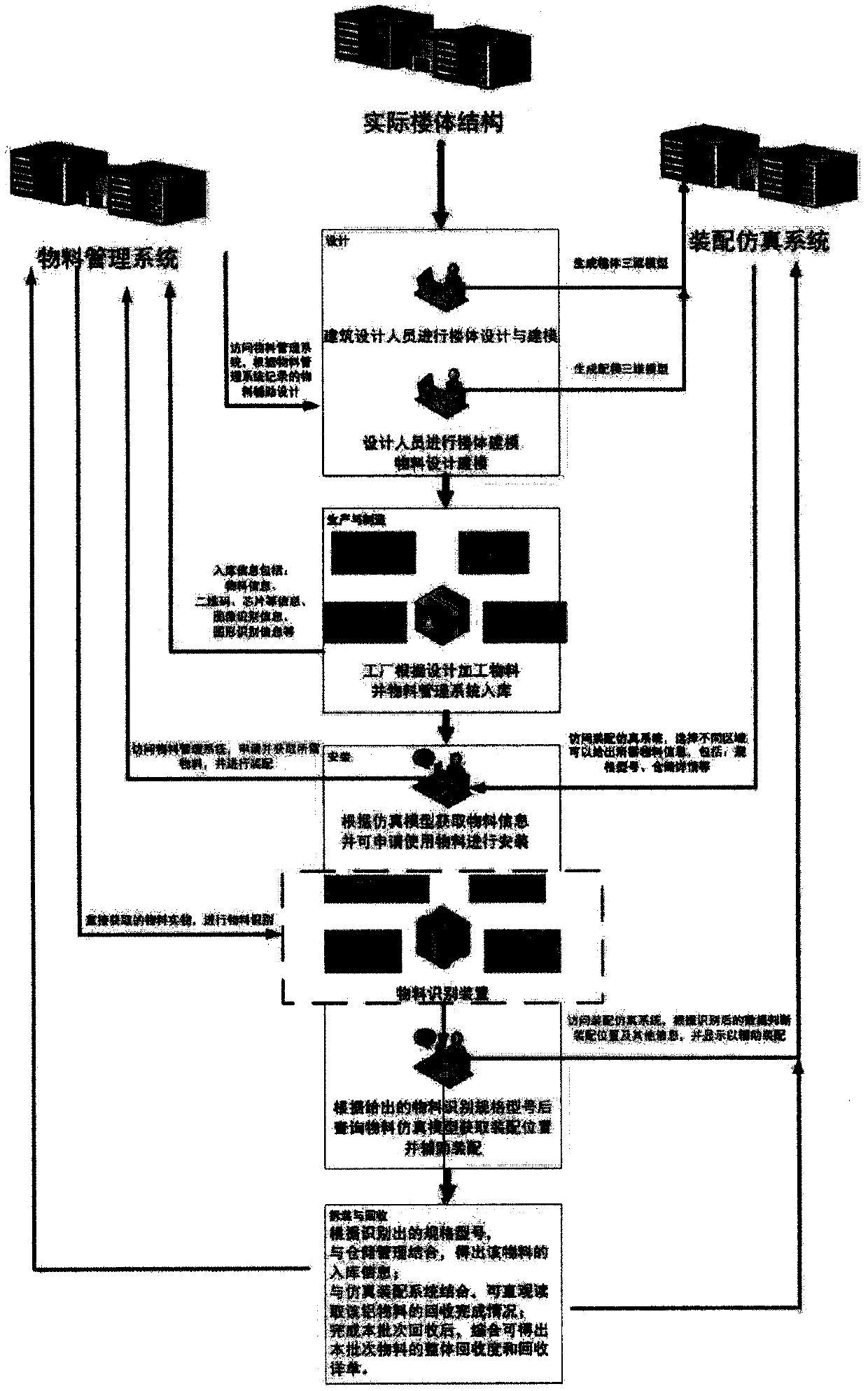

[0036] Embodiment 1, combining figure 1 , a material automatic identification and simulation assembly system, including

[0037] The assembly simulation system is used for designers to design material models and three-dimensional assembly of material models. It can display the assembly effect in real time and locate the assembly of each material model according to the size and specification data of the production materials.

[0038] The material management system is used to store materials, save data information of materials, and display the design, use and recycling of materials after 3D simulation modeling of actual materials.

[0039]The material identification system transmits the materials in sequence and identifies the image size information of the materials, marks and sorts the materials and puts them into storage; the material identification system is associated with the data of the assembly simulation system and the material management system, and is used to The mode...

Embodiment 2

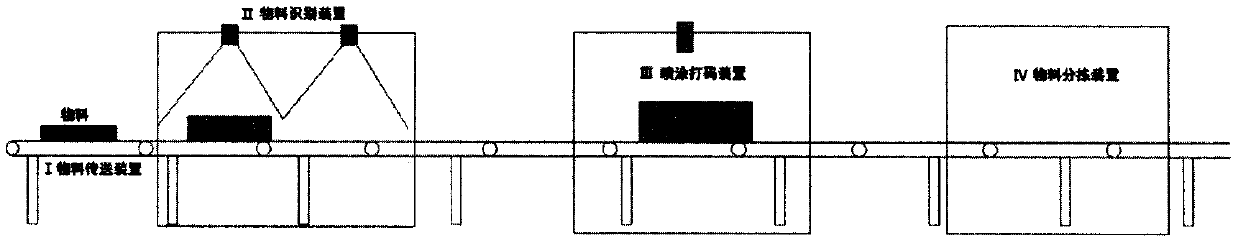

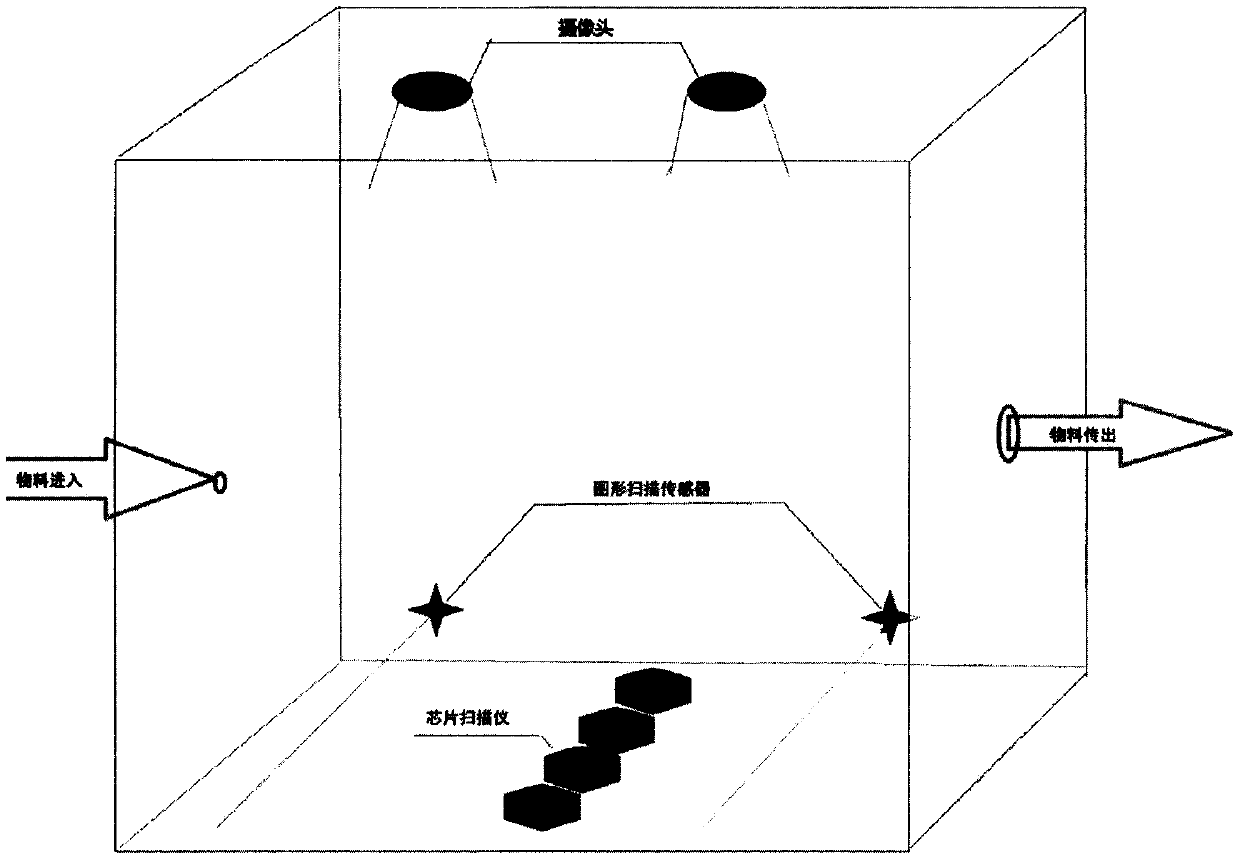

[0044] Example 2, combined with figure 2 , the material identification system includes a material transmission device for mechanical transmission of the material; a material identification device for identifying the image, shape and size of the material, or scanning and identifying the two-dimensional code set on the material or the built-in chip; for A spraying and coding device for spraying two-dimensional codes or laser marking on the identified materials; and a material sorting device for sorting, transferring and warehousing according to the identification data and coding data of the materials. That is, use the mature material conveying device on the existing market to transport the materials to be identified, and take pictures, scan or chip induction of the materials to be identified through an external imaging device and perform artificial intelligence comparison and identification. After identification, it can be read from the material management system Its detailed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com