Method and device for detecting surface of weld joint of nuclear fuel rod

A technology for welding seam surface and nuclear fuel rods, which is applied in image data processing, instruments, calculations, etc., can solve the problems that detection sensitivity cannot find small defects of fuel rods, and the influence of direction, so as to achieve the effect of rapid detection and unified detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

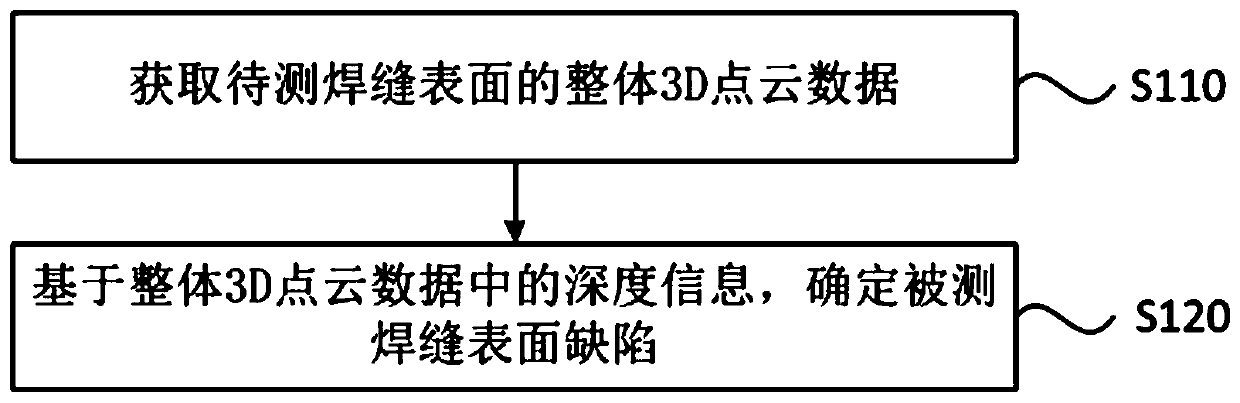

[0022] figure 1 It is a flow chart of a method for detecting the surface of a nuclear fuel rod weld seam provided by Embodiment 1 of the present invention. This embodiment is applicable to the situation of detecting surface defects of weld seam. Typically, this embodiment is applicable to the inspection of the weld seam at the end of nuclear fuel cladding. The method can be implemented by a device for detecting the surface of a weld seam of a nuclear fuel rod, and the device can be realized by software and / or hardware. like figure 1 As shown, a method for detecting the surface of a nuclear fuel rod weld provided in this embodiment may specifically include the following steps:

[0023] Step 110, acquiring the overall 3D point cloud data of the weld surface to be tested.

[0024] Wherein, the surface of the weld seam to be tested is the surface of the weld seam that needs to be inspected for defects.

[0025] Typically, the weld surface to be tested is the weld formed by ar...

Embodiment 2

[0070] Figure 4 It is a flow chart of a method for detecting the surface of a nuclear fuel rod weld seam provided by Embodiment 2 of the present invention. This embodiment is an optional solution proposed on the basis of the foregoing embodiments. Such as Figure 4 As shown, a method for detecting the surface of a nuclear fuel rod weld provided in this embodiment may specifically include the following steps:

[0071] Step 410, acquiring the overall 3D point cloud data of the weld surface to be tested.

[0072] Step 420, based on the depth information in the overall 3D point cloud data, determine the surface defect of the weld seam to be tested.

[0073] Step 430: Determine at least two defect elements from each defect according to the number of rows and columns included in each defect on the surface of the weld to be tested.

[0074] Wherein, each of the above-mentioned defects is a defect area included in the surface defects of the weld.

[0075] Specifically, for each ...

Embodiment 3

[0099] Figure 5 A structural diagram of a device for detecting the surface of a nuclear fuel rod weld seam provided by Embodiment 3 of the present invention. A method for surface detection of nuclear fuel rod welds provided by any embodiment of the present invention can be implemented, see Figure 5 , a device for nuclear fuel rod weld surface inspection provided by an embodiment of the present invention includes: a 3D point cloud data acquisition module 510 and a surface defect determination module 520 .

[0100] Wherein, the 3D point cloud data acquisition module 510 is used to acquire the overall 3D point cloud data of the weld surface to be tested.

[0101] The surface defect determining module 520 is configured to determine the surface defect of the weld seam to be tested based on the depth information in the overall 3D point cloud data.

[0102]The embodiment of the present invention realizes automatic defect detection on the surface of the weld to be tested based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com