Halogen-free synergistic composite flame retardant and preparation method thereof

A composite flame retardant and organic solvent technology, which is applied in the fields of chemical materials and light industry, can solve problems such as easy agglomeration, poor dispersion, unfavorable flame retardancy and mechanical properties of high molecular polymers, and achieve high flame retardancy , improved dispersion, good smoke suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

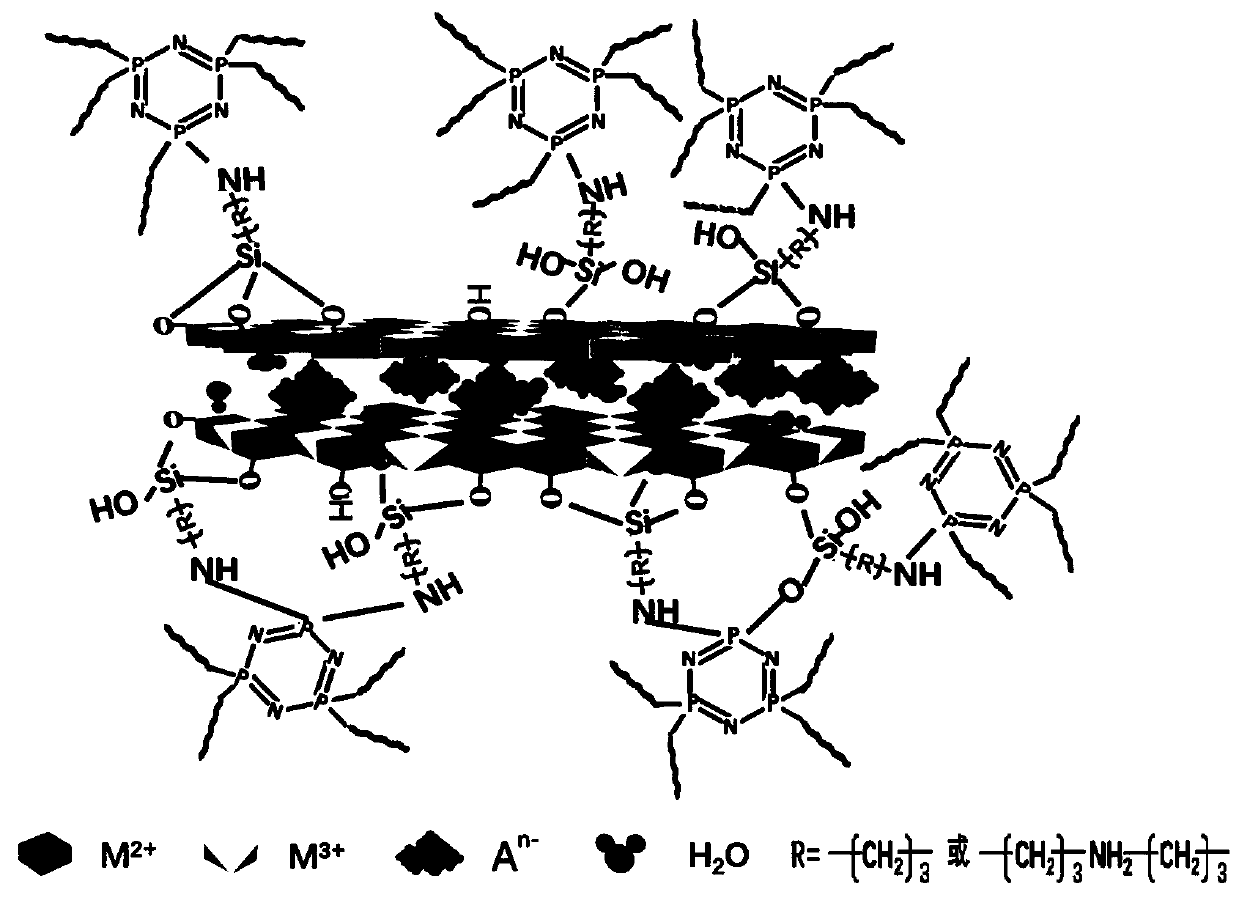

[0053] A halogen-free synergistic composite flame retardant is composed of hydrotalcite-like modified by anion intercalation and hexachlorocyclotriphosphazene through an in-situ chemical reaction through a silane coupling agent, and has a layered structure.

[0054] Among them, the hydrotalcite-like modified by anion intercalation has Figure 6 indicated chemical structure.

[0055] The preparation method of above-mentioned a kind of halogen-free synergistic composite flame retardant, it comprises the following steps:

[0056] The first step, the preparation of anion-intercalation-modified hydrotalcite-like: the anion-intercalation-modified Hydrotalcite-like;

[0057] The second step, the preparation of the halogen-free synergistic composite flame retardant: filter and wash the anion-intercalated modified hydrotalcite-like obtained in the first step to be neutral, and disperse it with an organic solvent to obtain a dispersion liquid, Then hexachlorocyclotriphosphazene dissol...

Embodiment 2

[0059] A halogen-free synergistic composite flame retardant is composed of hydrotalcite-like modified by anion intercalation and hexachlorocyclotriphosphazene through an in-situ chemical reaction through a silane coupling agent, and has a layered structure.

[0060] Among them, the hydrotalcite-like modified by anion intercalation has Figure 6 indicated chemical structure.

[0061] In this embodiment, the particle size of the hydrotalcite-like modified by anion intercalation is 15 μm.

[0062] The preparation method of above-mentioned a kind of halogen-free synergistic composite flame retardant, it comprises the following steps:

[0063] The first step, the preparation of anion-intercalation-modified hydrotalcite-like: the anion-intercalation-modified Hydrotalcite-like;

[0064] The second step, the preparation of the halogen-free synergistic composite flame retardant: filter and wash the anion-intercalated modified hydrotalcite-like obtained in the first step to be neutral...

Embodiment 3

[0074] A halogen-free synergistic composite flame retardant is composed of hydrotalcite-like modified by anion intercalation and hexachlorocyclotriphosphazene through an in-situ chemical reaction through a silane coupling agent, and has a layered structure.

[0075] Among them, the hydrotalcite-like modified by anion intercalation has Figure 6 indicated chemical structure.

[0076] In this embodiment, the particle size of the hydrotalcite-like modified by anion intercalation is 10 μm.

[0077] The preparation method of above-mentioned a kind of halogen-free synergistic composite flame retardant, it comprises the following steps:

[0078] The first step, the preparation of anion-intercalation-modified hydrotalcite-like: the anion-intercalation-modified Hydrotalcite-like;

[0079] The second step, the preparation of the halogen-free synergistic composite flame retardant: filter and wash the anion-intercalated modified hydrotalcite-like obtained in the first step to be neutral, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com