High-temperature phase-change wax and preparation method thereof

A high-temperature phase change and wax-supporting technology, applied in the field of phase change energy storage, can solve problems such as no related reports, achieve the effects of improving product quality and yield, facilitating separation, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of high-temperature phase-change wax, comprising:

[0030] Step 1: Use coal-based Fischer-Tropsch wax as raw material to carry out hydrogenation refining, and use a small amount of olefins in saturated Fischer-Tropsch wax, a small amount of oxygen-containing organic compounds in hydrogenation reduction Fischer-Tropsch synthetic wax and hydrogenation fracture Fischer-Tropsch synthetic wax A small amount of polycyclic hydrocarbons. If these substances are not removed, on the one hand, they will affect the chromaticity of the Fischer-Tropsch synthetic wax, and on the other hand, it is easy to cause coking and carbon deposition in subsequent processing, thereby affecting product quality and normal production.

[0031] Step 2: After preheating the refined wax obtained in step 1, perform pre-short-path distillation cutting to remove light fractions. Due to the wide distillation range of Fischer-Tropsch wax and the large proportion of heavy components, ord...

Embodiment 1

[0048] Coal-based Fischer-Tropsch wax obtained by Fischer-Tropsch synthesis process is used as raw material, and Fischer-Tropsch refined wax is obtained through hydrogenation refining. The hydrogenation temperature is 260-300°C and the operating pressure is 5-8Mpa.

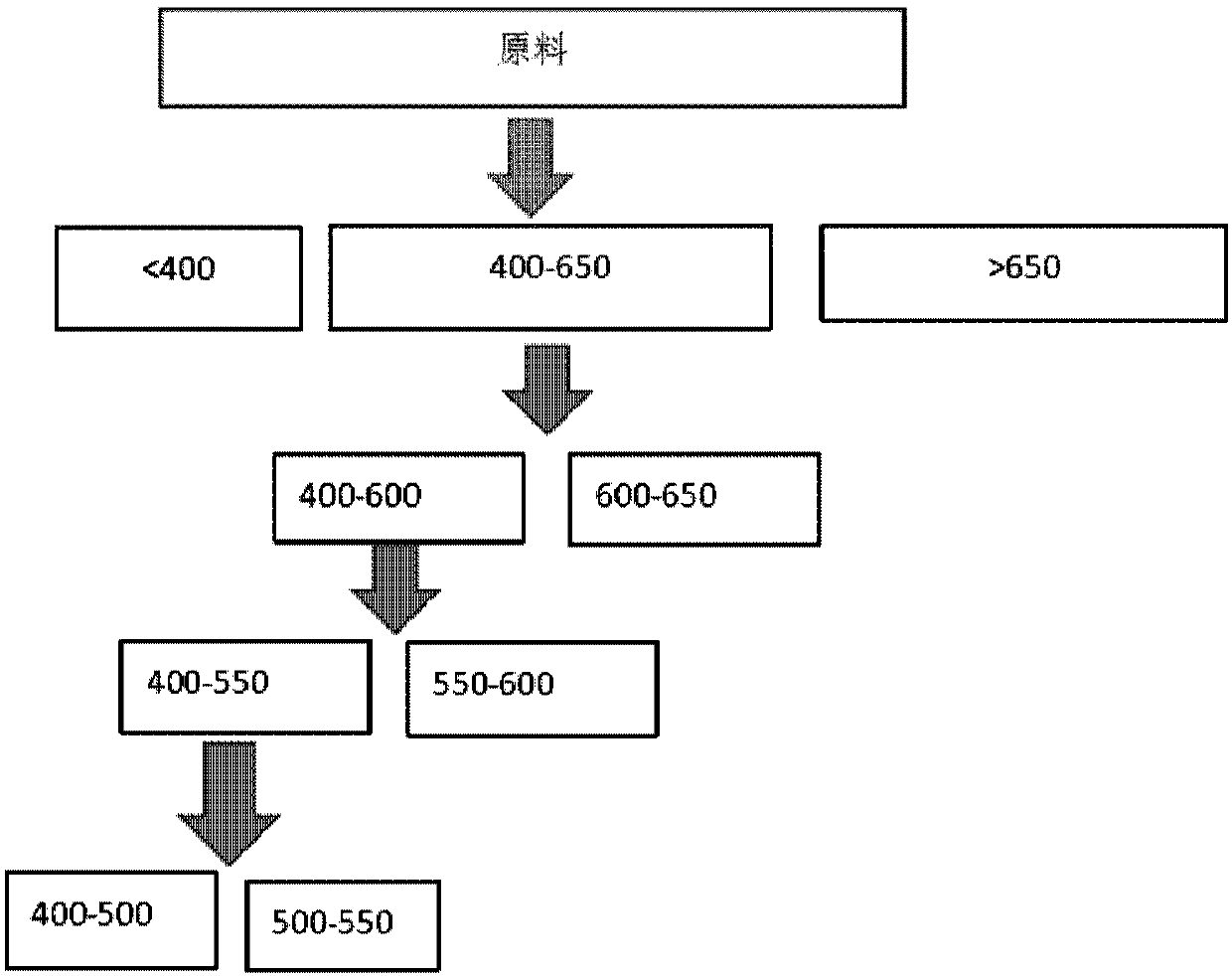

[0049] Such as figure 1 As shown, the coal-based Fischer-Tropsch refined wax is preheated to 110°C in the raw material tank, and sent to the first molecular evaporator at a feed rate of 6kg / h for pre-short-path distillation. The temperature of the first evaporator is controlled at 195°C , pressure 45pa, the first evaporator removes light components 650°C distillate section.

[0050] The 400-650°C distillate section is used as the raw material, and the second-stage short-path distillation is carried out in the second evaporator, the temperature is controlled at 305°C, and the pressure is 0.3pa to obtain the 400-600°C and 600-650°C distillate section, of which 600-650 The ℃ distillate section is refined to obtain a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Enthalpy | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com