Protective agent for aged paper sheet and protection method of aged paper sheet

A protective agent and paper technology, which is applied in papermaking, waste paper post-processing, textiles and papermaking, etc., can solve the problems that cannot be further popularized, high requirements, complicated process, etc., achieve good repair and removal effect, high protection efficiency, The effect of sufficient raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Accurately measure 49.75g of absolute ethanol and 49.75g of ionic liquid into a beaker, then add 0.5g of nanocellulose, put it in a sealed container, heat up to 90°C to dissolve, stir and mix well, put it in a sealed container and use it directly on four sides Apply the paper to be treated with the applicator, brush back and forth at 25°C for 10-15mins; put the treated paper in a vacuum drying oven at 75°C for 3 hours, take it out to room temperature, wash it with ethanol, at 25°C, 50% Dry naturally under low humidity.

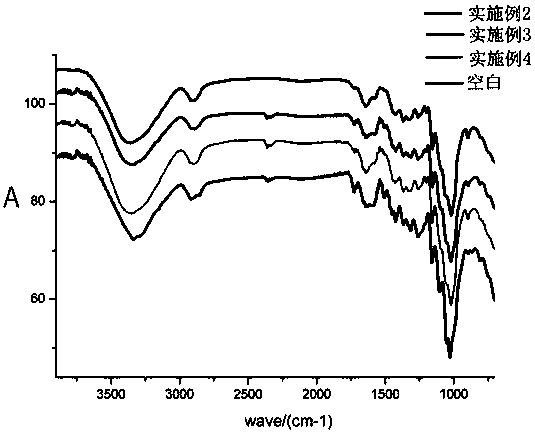

[0096] Characterization of old aged paper prior to treatment in the present invention.

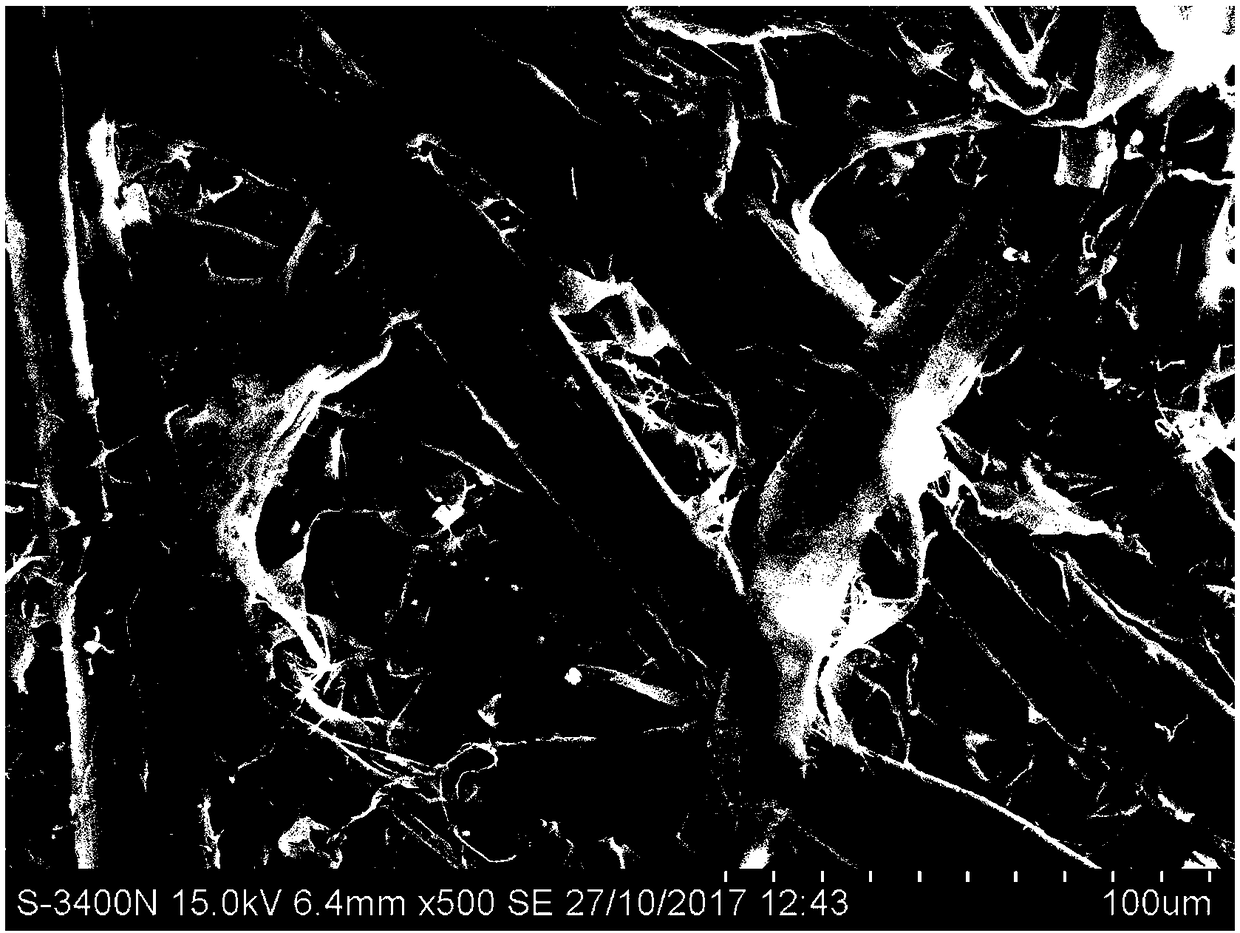

[0097] see figure 1 , figure 1 It is the SEM scanning electron micrograph of the whole picture of the paper fiber before the old aging paper is unprotected.

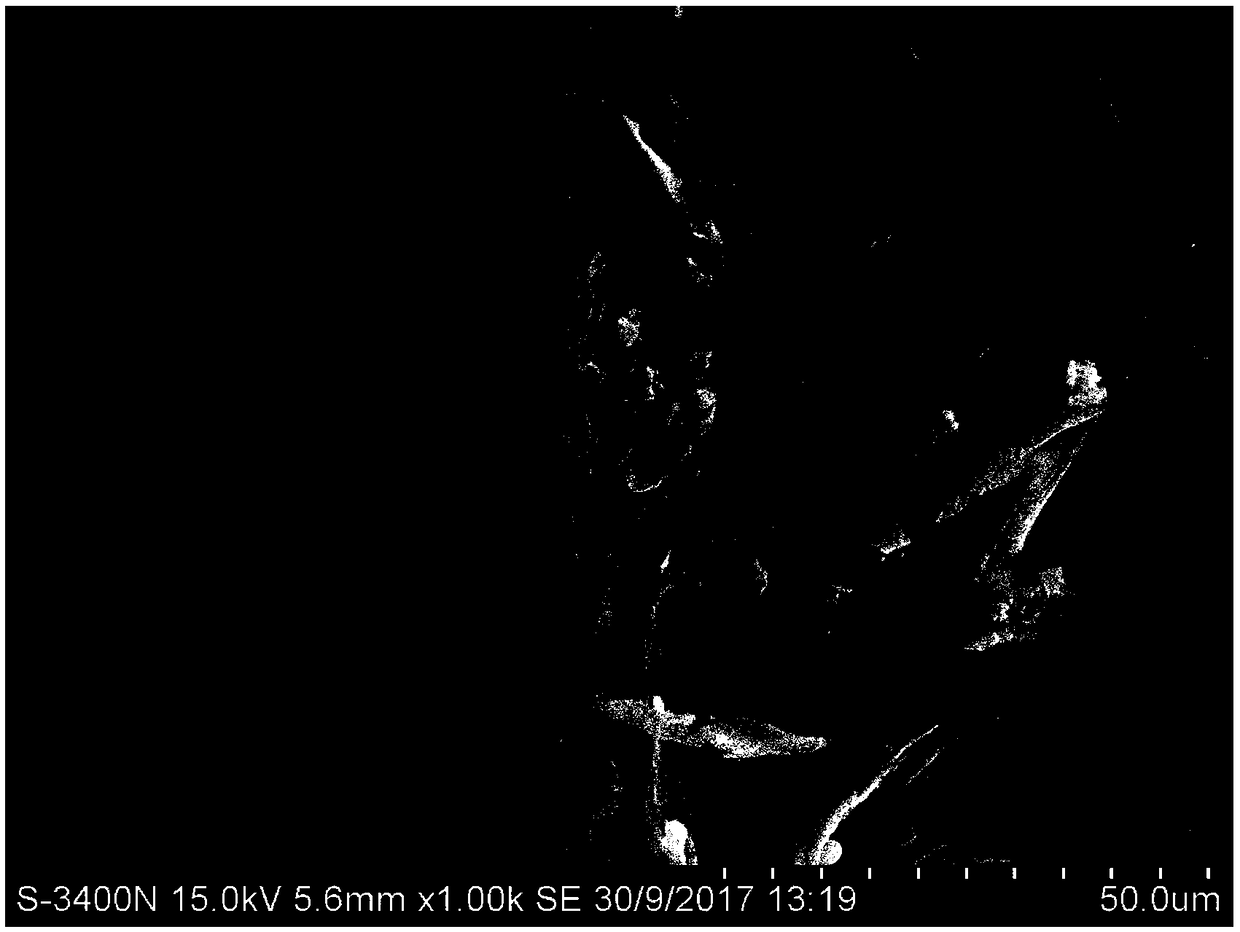

[0098] see figure 2 , figure 2 It is the SEM scanning electron microscope picture of the paper fiber section of the old aging paper before protection.

[0099] Characterize the old and aged paper treat...

Embodiment 2

[0108] Accurately measure 49.625g of absolute ethanol and 49.625g of ionic liquid into a beaker, then add 0.75g of nanocellulose, stir and mix thoroughly, place in a sealed container, heat up to 90°C to dissolve, stir and mix thoroughly Evenly, put it in a sealed container and directly apply the paper to be treated with a four-sided applicator, brush back and forth at 25°C for 10-15mins; put the treated paper in a vacuum drying oven at 75°C for 3 hours, take it out and cool it to room temperature, and use Wash with ethanol and dry naturally at 25°C and 50% humidity.

[0109] The properties and indexes of the old aged paper after treatment in Example 2 of the present invention are compared with those before treatment.

[0110] Referring to Table 2, Table 2 shows the properties and indexes of the paper before and after treatment in Example 2.

[0111] Table 2

[0112]

Embodiment 3

[0114] Accurately measure 49.5g of anhydrous ethanol and 49.5g of ionic liquid into a beaker, add 1.00g of nanocellulose, put it in a sealed container, heat up to 90°C to dissolve, stir and mix evenly, put it in a sealed container and directly use four-sided coating Apply the cloth to the paper to be treated, brush back and forth at 25°C for 10-15mins; put the treated paper in a vacuum drying oven at 75°C for 3 hours, take it out to room temperature, wash it with ethanol, at 25°C, 50% Dry naturally under humidity.

[0115] The properties and indexes of the old aged paper after treatment in Example 3 of the present invention are compared with those before treatment.

[0116] Referring to Table 3, Table 3 shows the properties and indexes of the paper before and after treatment in Example 3.

[0117] table 3

[0118]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com