Multi-layer filter paper and preparation method thereof

A filter paper, double-layer technology, applied in the field of multi-layer filter paper and its preparation, can solve the problems of clogging pores by adhesive, easy falling off of filter paper, increase manufacturing cost, etc., achieve good dust holding capacity and filtering accuracy, simplify manufacturing process, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Example Preparation of multi-layer filter paper

[0062] 1. Composition and ratio of multi-layer filter paper

[0063] The raw material compositions and proportioning ratios of Examples 1-5 and Comparative Examples 1-4 are shown in Table 1.

[0064] Table 1

[0065]

[0066]

[0067]

[0068] 2. Preparation of multi-layer filter paper

[0069] The preparation method of above-mentioned embodiment 1-4, comparative example 2-3 is as follows:

[0070] 1) Preparation of dense layer slurry

[0071] According to the composition of the dense layer, prepare raw plant fibers and single melting point synthetic fibers, mix with water, and beat to obtain the dense layer slurry;

[0072] 2) Preparation of loose layer slurry

[0073] Prepare the raw materials according to the formula composition of the loose layer, mix with water, and beat to obtain the loose layer slurry;

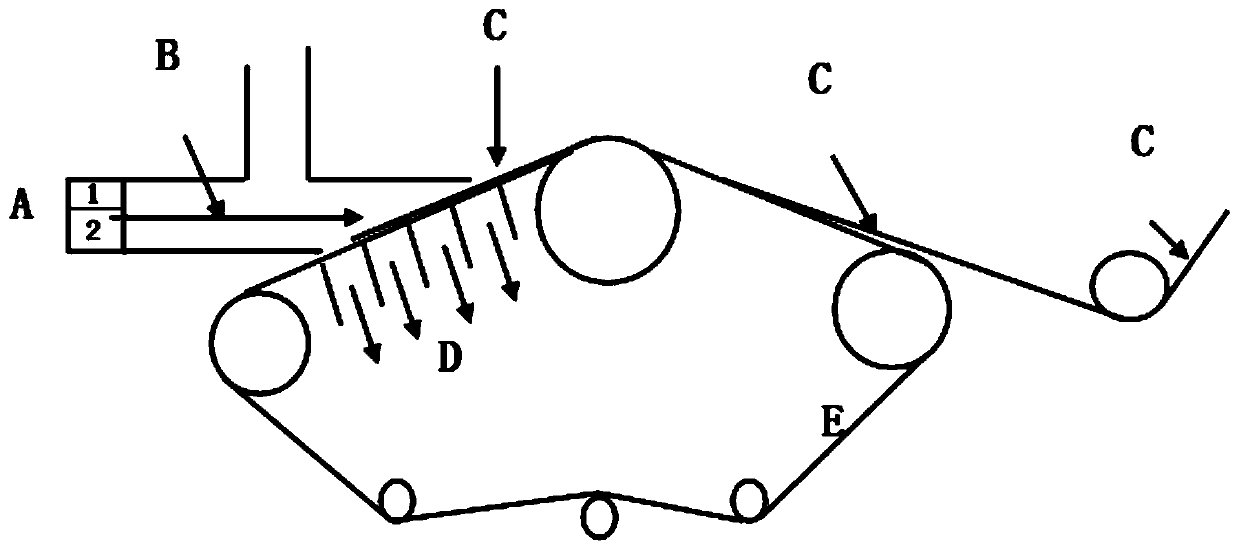

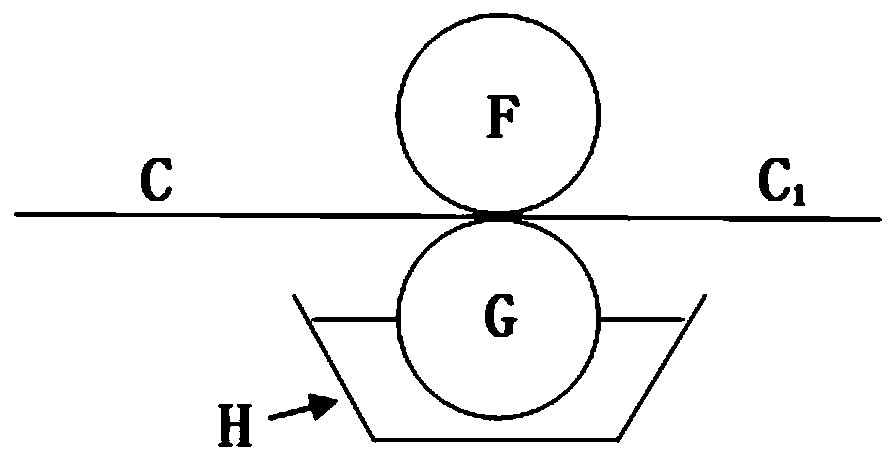

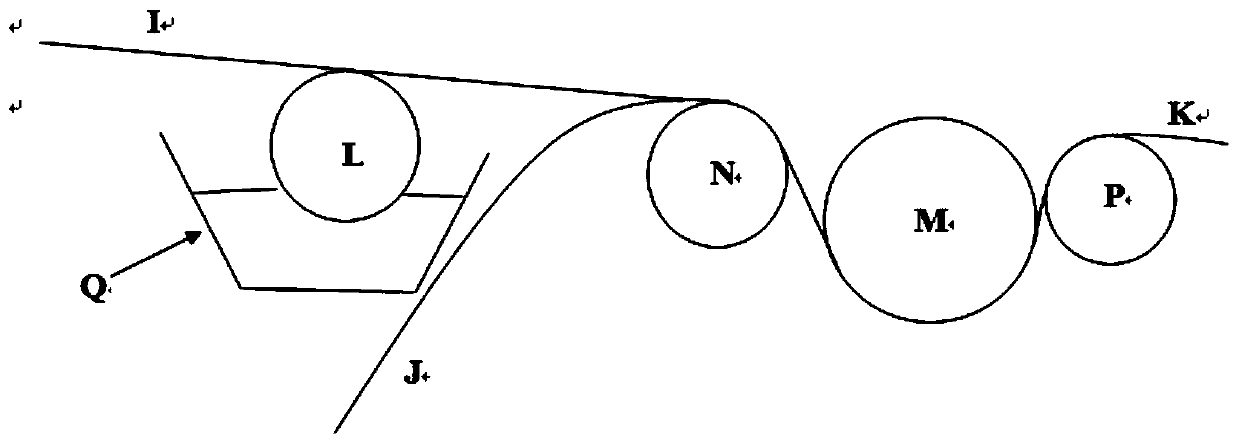

[0074] 3) on an inclined wire paper machine or a Fourdrinier paper machine with more than two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tightness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com