Building block and construction process thereof

A technology for building blocks and construction technology, which is applied to buildings, building components, building structures, etc., can solve problems such as low efficiency, and achieve the effects of simple construction technology, high work efficiency, and improved structural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

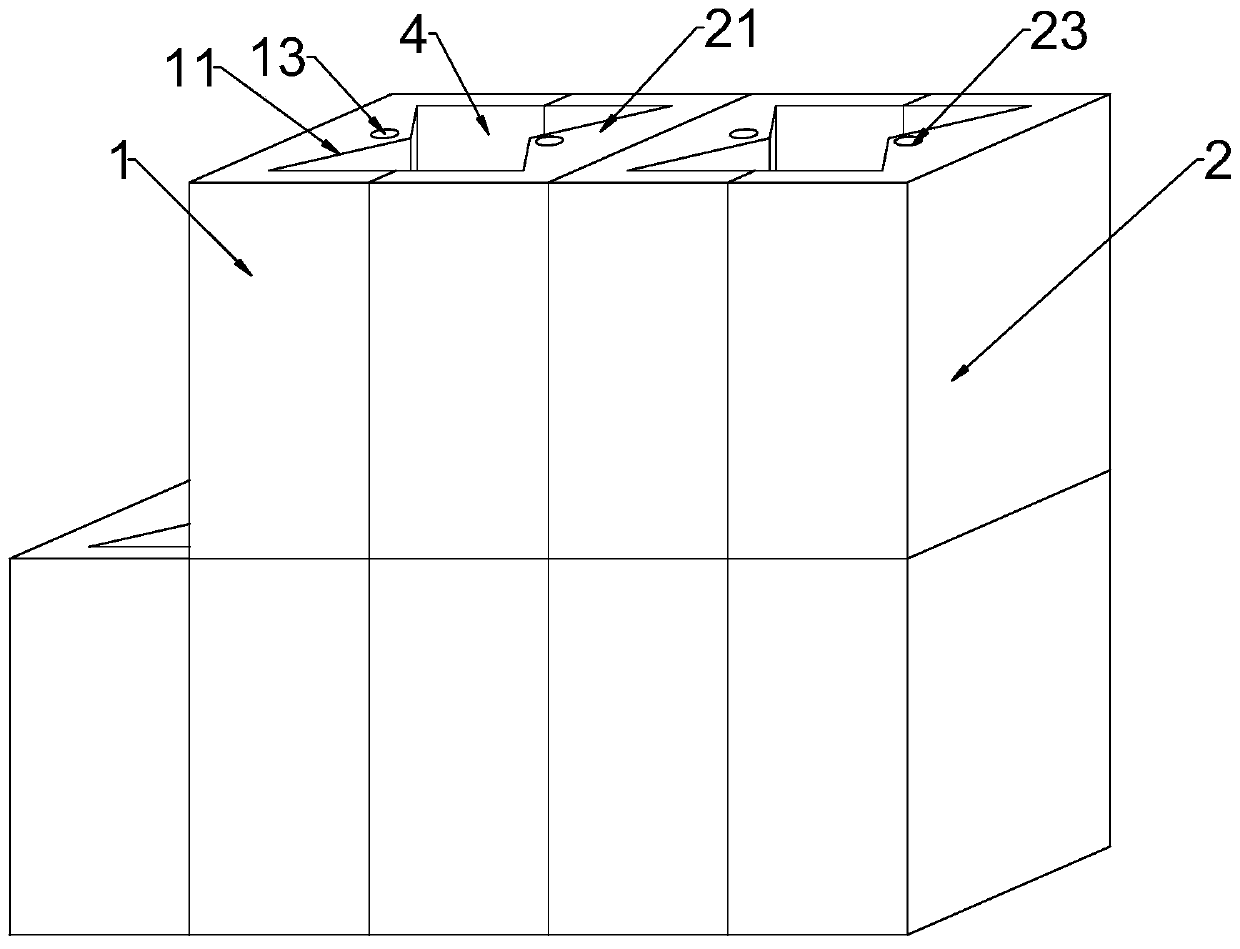

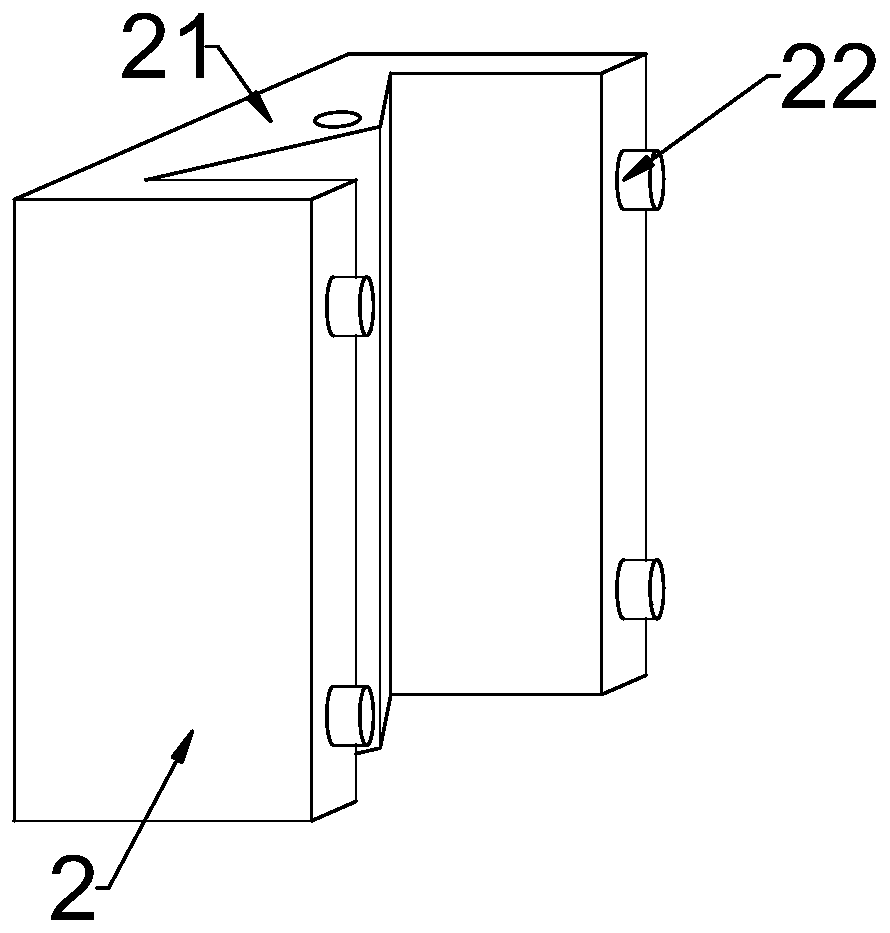

[0034] see Figure 1~3 , in an embodiment of the present invention, a building block, including multiple groups of block structures arranged in sequence in the horizontal direction and stacked in the vertical direction, the block structure is composed of symmetrically arranged first block 1 and second block structure The blocks 2 are movably assembled and connected. After the first block 1 and the second block 2 are assembled, a sound-insulating cavity 4 is formed in the middle, and the sound-insulating cavity 4 is respectively arranged on the first block 1 and the second block 2. The first rib 11 and the second rib 21 refract sound waves.

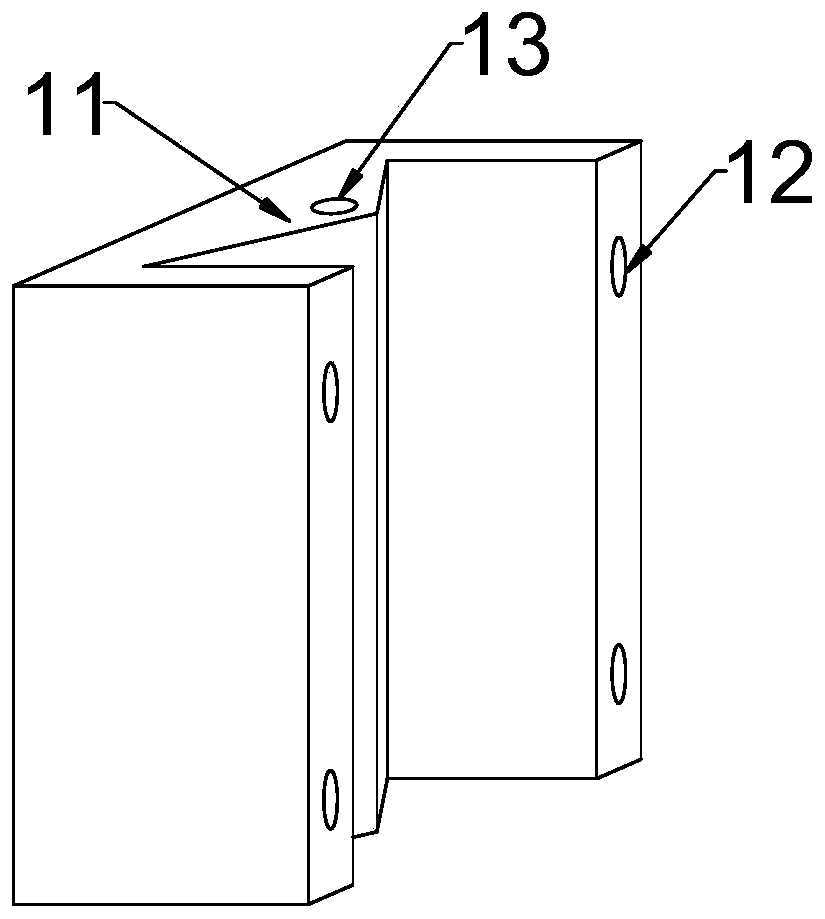

[0035] Both the first block 1 and the second block 2 are hollow cuboid concrete blocks of the same size, and the opposite sides of the first block 1 and the second block 2 are open.

[0036] The inside of the first block 1 is provided with a first reinforcing rib 11, the first reinforcing rib 11 is an integrally formed prismatic structure...

Embodiment 2

[0047] see Figure 4~5, in order to keep the level of the block structure on the first floor in the horizontal direction, it needs to be adjusted several times when each group of block structures is placed to ensure that the horizontal direction is flush, but this is inefficient, so on the basis of Example 1 Above, in the embodiment of the present invention, a building block, the outer surfaces of the first block 1 and the second block 2 are embedded with multiple sets of third limiting holes 3, and the third limiting holes 3 are respectively located at the corners of the four sides of the outer surface of the first block 1 and the second block 2; the third limiting hole 3 is movably connected with a connecting gasket 5, and the connecting gasket 5 is fitted and arranged on the On the surface of the third limiting hole 3, the two sides of the connecting gasket 5 are symmetrically fixedly connected with a limiting protrusion 51, and the limiting protrusion 51 is a semi-spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com