Temporary support system integrating automatic net laying, dust removal device, and forward detection functions

A technology of temporary support and dust removal device, which is applied in the direction of shaft equipment, mine roof support, mine/tunnel ventilation, etc., and can solve the problems of inability to realize automatic net laying and dust removal, inability to achieve zero empty head distance, and high dust concentration of working flour and other problems to achieve the effect of shortening the empty head distance, improving stability and reliability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

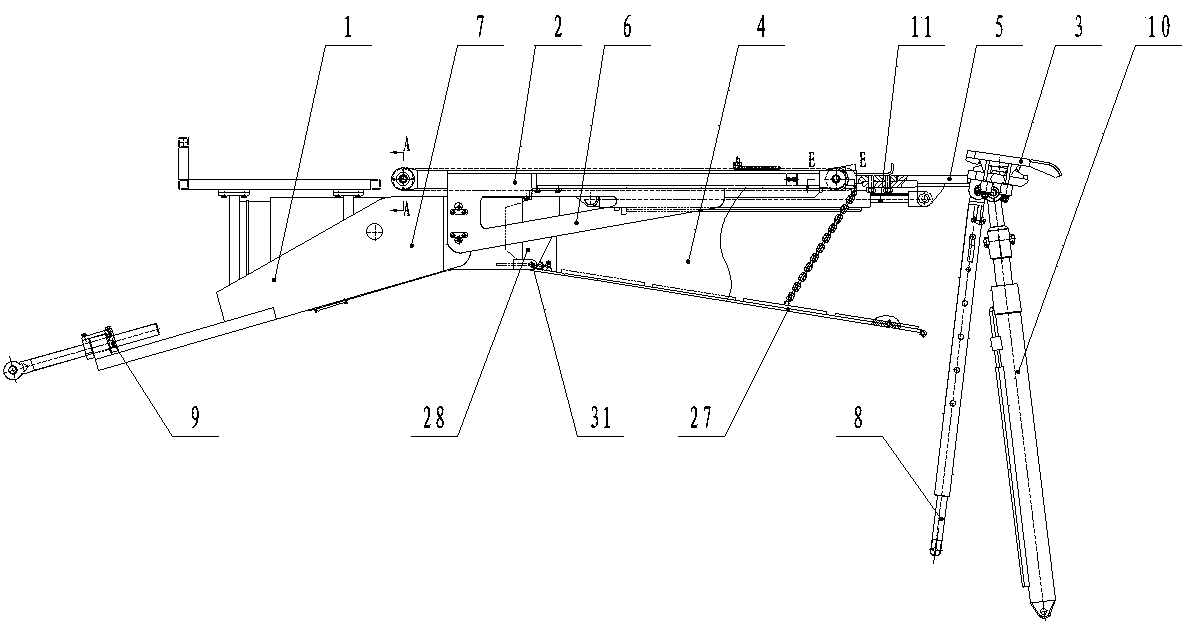

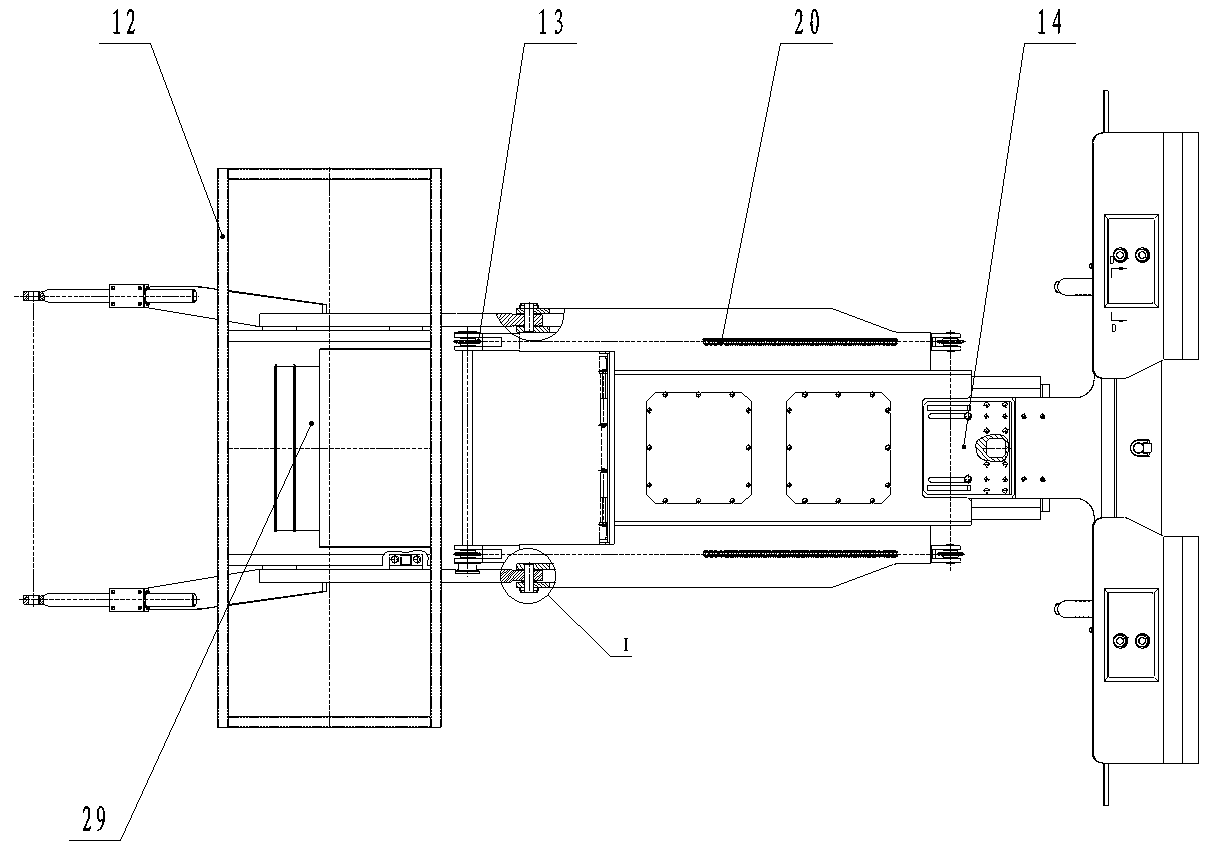

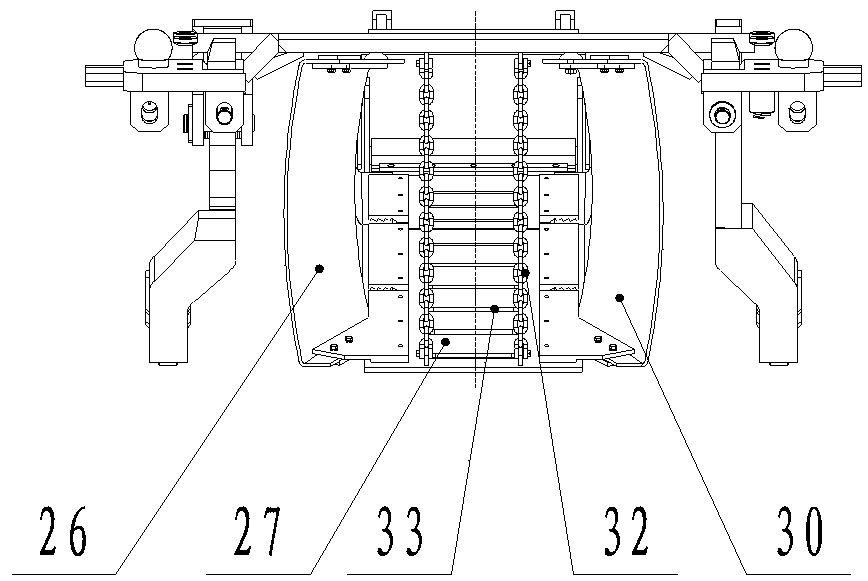

[0032] The specific implementation of the present invention will be further described in conjunction with the accompanying drawings, and the embodiments are used to illustrate the present invention, but not to limit the present invention in any way.

[0033] Such as figure 1 , 2 As shown, the present invention integrates the temporary support system of automatic net laying, dust removal device and forward detection function. The temporary support mechanism 1, the automatic net laying mechanism 2 used for anchor net storage, transportation and hang-up, are arranged The self-adaptive adjustment roof structure 3 supporting the front end is composed of a closed air guide channel 4 for the passage of dust flow on the working face. The temporary support system is generally integrated into the complete machine system of the bolter digging machine. The lower end of the strut mechanism 8 at the front end of the temporary support mechanism 1 is designed with a mounting hole, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com