Fixed point wavelength modulation gas concentration measurement device and measurement method based on wave number drift correction

A gas concentration measurement and drift correction technology, which is applied in the field of optical measurement, can solve the problems that the database cannot meet the measurement requirements, the wave number drift of the laser output center, and the impact on the accuracy of gas concentration measurement, etc., to achieve long-term stable monitoring and spectrum Narrow range, beneficial to the effect of multi-spectral coupling measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings, but the scope of protection claimed by the present invention is not limited thereto.

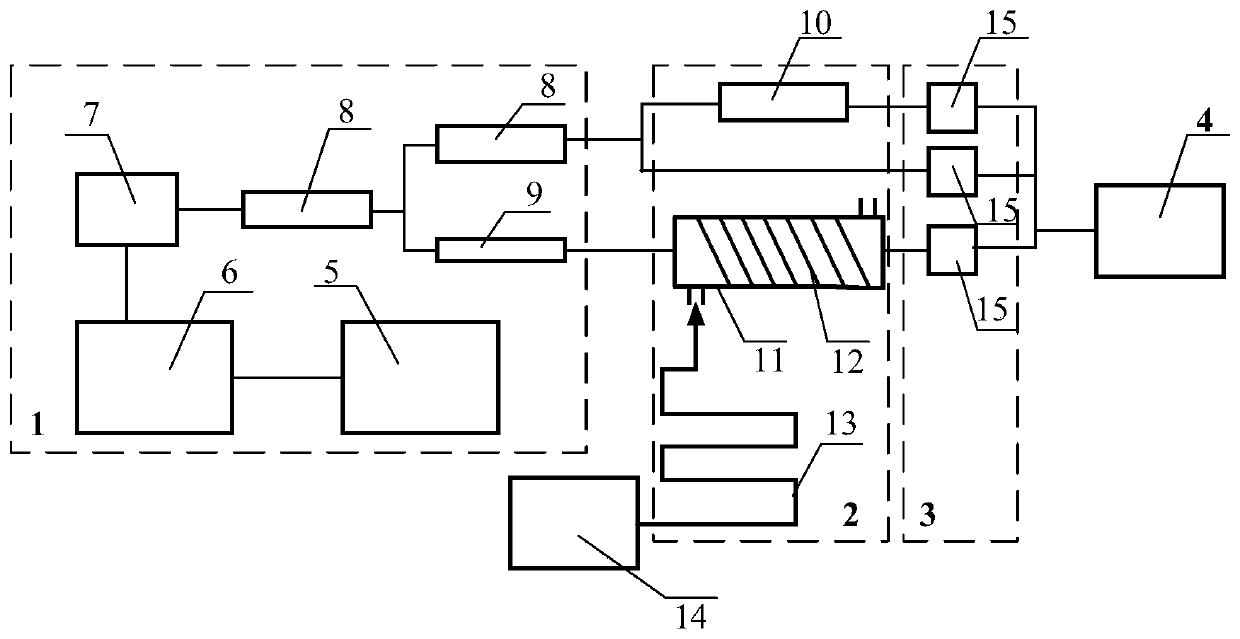

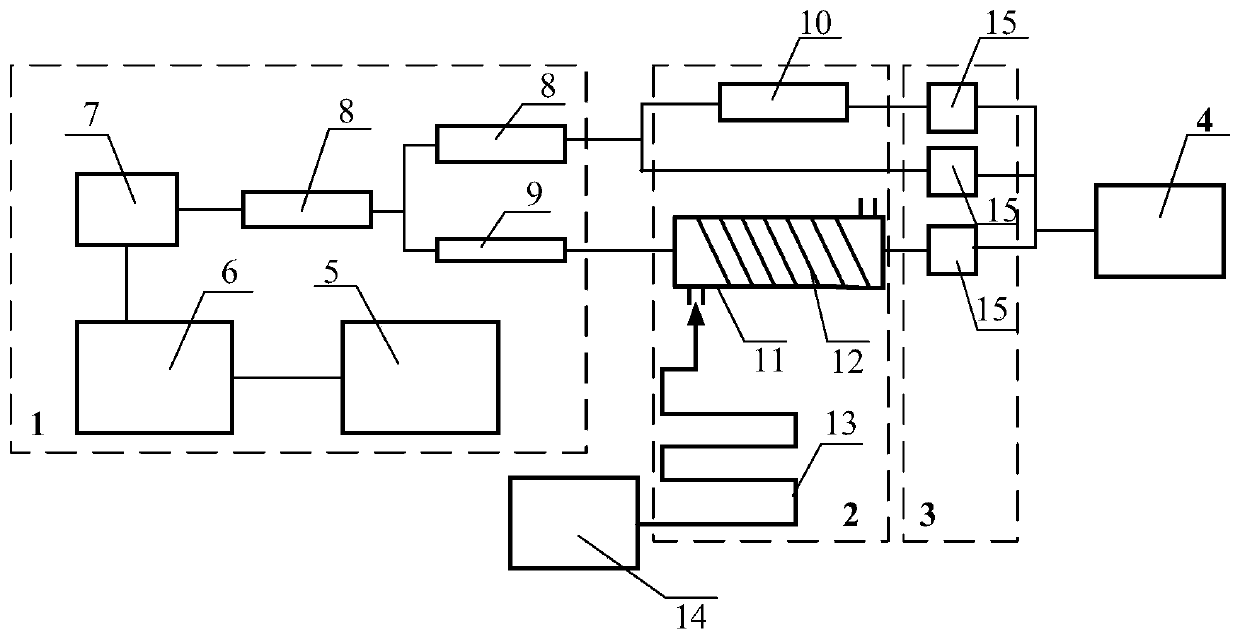

[0041] Such as figure 1 As shown, the fixed-point wavelength modulation gas concentration measurement device based on wave number drift correction of the present invention sequentially includes a signal generation module 1, a gas measurement module 2, a signal receiving module 3 and a signal processing module 4; the signal generation module 1 includes a function generator 5 , laser controller 6, distributed feedback laser (DFB) 7, fiber optic beam splitter 8 and fiber optic collimator 9; The heating module 12 outside 11; the signal receiving module 3 is composed of three photodetectors 15; the gas 14 to be measured enters the measuring pool 11 with gas after being preheated by the heating pipe belt 13, and the heating module 12 keeps the measuring pool 11 maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com