Capillary focusing microbeam X-ray diffractometer

An X-ray and capillary technology, applied in the fields of X-ray diffraction technology and energy dispersive X-ray fluorescence, can solve the problems of complex and expensive equipment, the inability to detect the chemical composition information of samples and the two-dimensional distribution of elements, and reduce power consumption and cost , the effect of increasing the resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

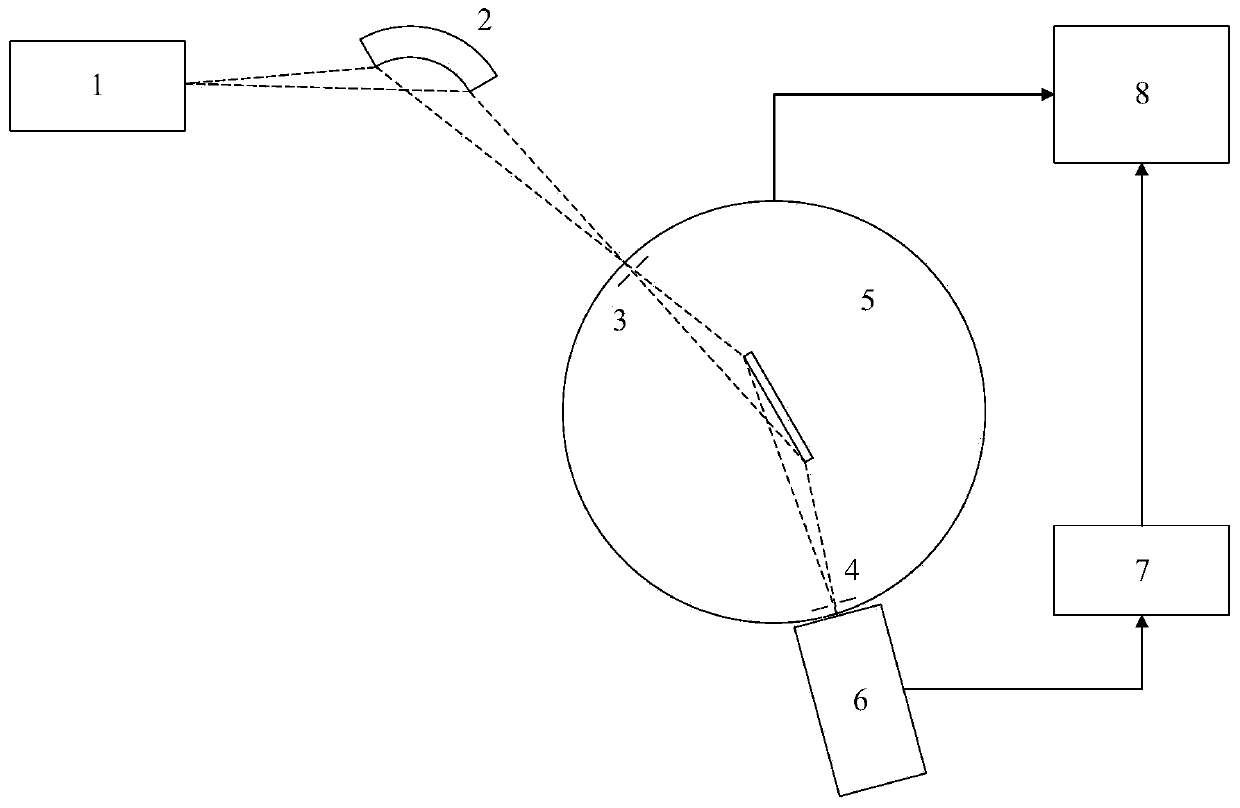

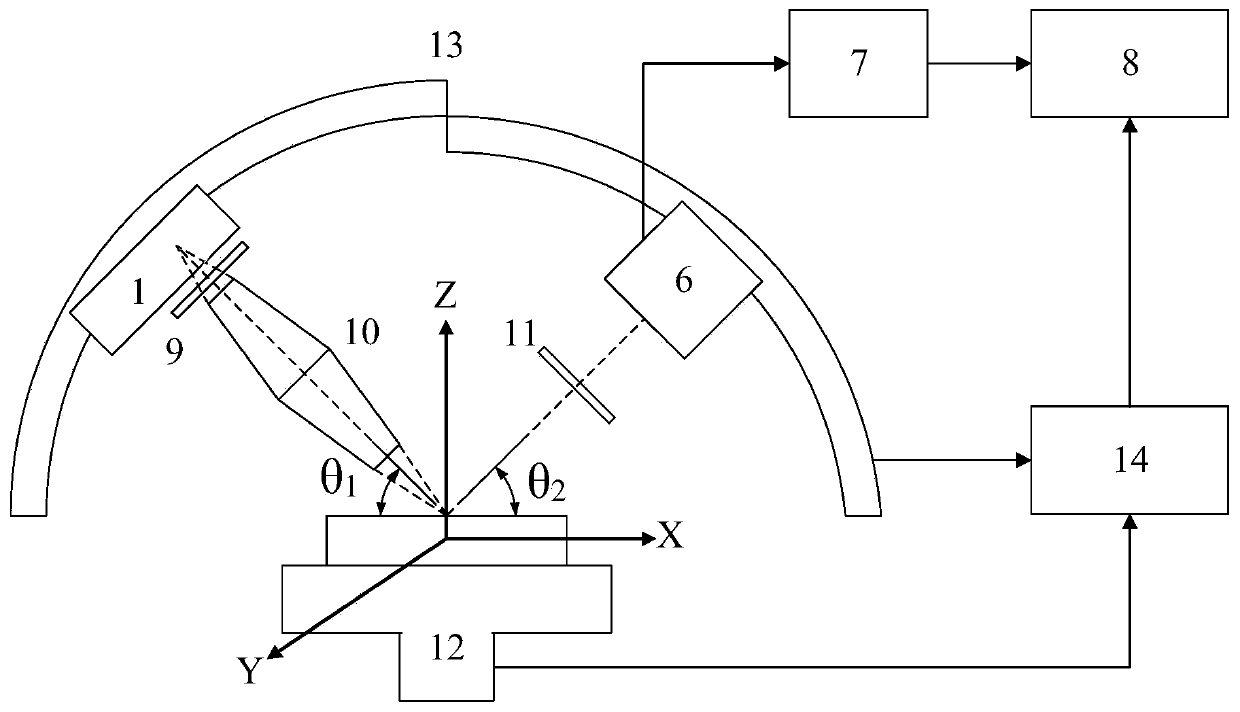

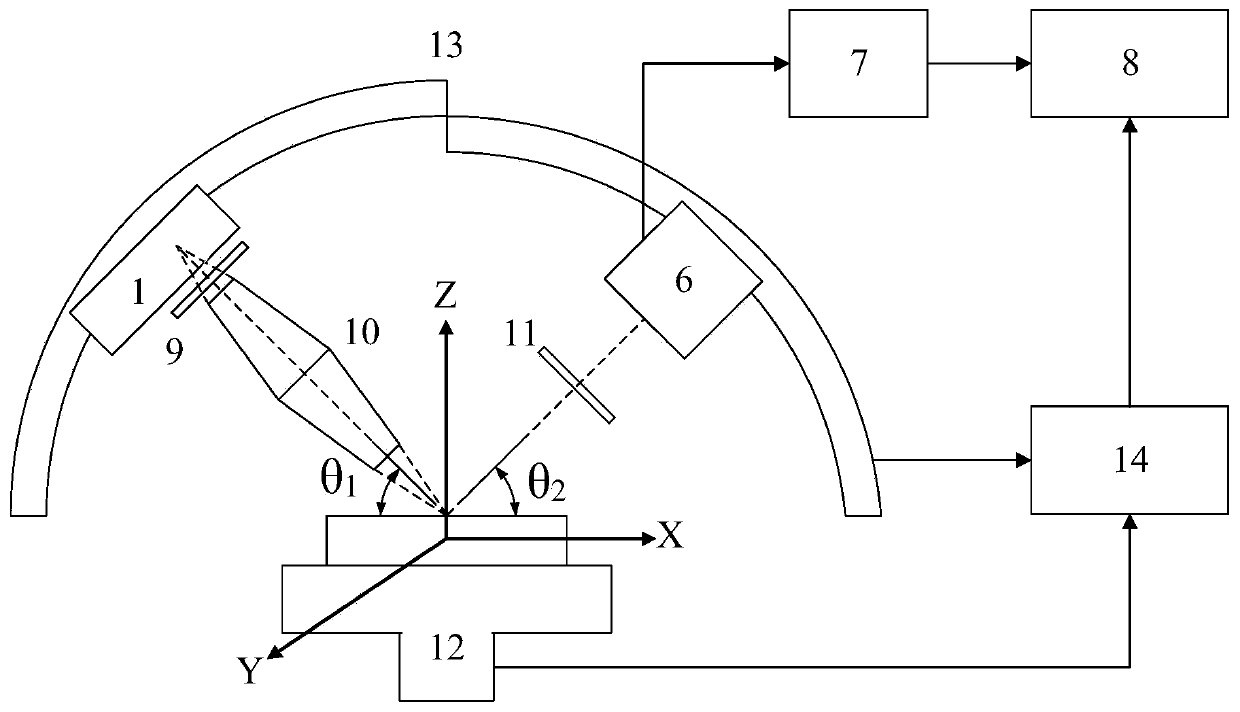

[0023] See attached figure 2 , the present invention provides a micro-beam X-ray diffractometer with capillary focusing, comprising an X-ray source system 1, an X-ray filter 9, a capillary converging X-ray lens 10, a receiving slit 11, a three-dimensional sample stage 12, and a goniometer 13. X-ray detector 6, electronics system 7, control system 14 and computer 8; wherein, X-ray source system 1 consists of Composed of a micro-focus spot X-ray tube of 50 microns and a maximum power of 30 watts, a temperature control device and a cooling fan; the diameter of the X-ray beam spot irradiated on the sample by the capillary converging X-ray lens 10 is 0.1mm, and the spot of the sample to be measured The distance to the capillary converging X-ray lens is 27.6 mm; the length of the receiving slit 11 is 20 mm, and the width is 0.1 mm; the distance from the sample point to be measured to the receiving slit 11 is 62.6 mm, and the receiving slit 11 is to the X-ray detector 6 The distan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com