V type positive plate

An anode plate and flat plate technology, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problem that the inlet and outlet speakers do not have the function of dust collection, and achieve the effects of high cost performance, simple structure and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

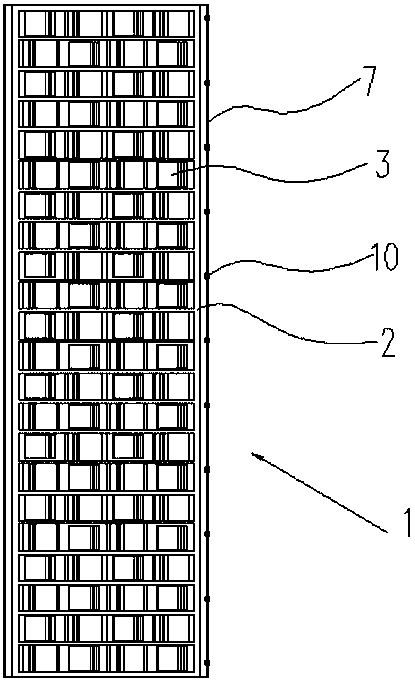

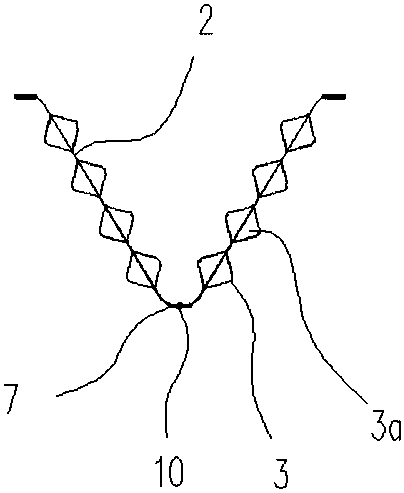

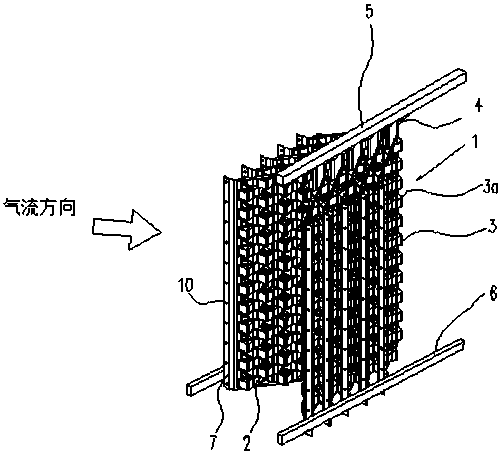

[0016] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a V-shaped anode plate provided by the present invention is characterized in that: it includes a V-shaped folded plate 1 formed by folding and pressing a flat plate, and each of the V-shaped folded plates 1 is provided with a reinforcement keel 7 at the trough and its periphery. It is a flat iron piece, and two flat iron pieces are cooperated and reinforced on the trough or the periphery of the V-shaped folding plate 1 by rivets 10 . The planar plate 2 on each side of the V-shaped folding plate 1 is evenly and densely covered with bulging convex hulls 3, and each convex hull 3 is provided with a through hole 3a, that is, the V-shaped folding plate 1 is a punched steel plate, and the opening The porosity is 30%~60%, the length of a single piece is 4m~12m, and it is processed into a "V" shape by special equipment, and the unfolded width is 0.5m~1.2m. The protrusions 3 of the through holes 3a on each side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com