Electric pole and tower formed by winding fibers and manufacturing method thereof

A power tower, winding forming technology, applied in the field of power towers, can solve problems such as construction and transportation difficulties, hidden safety hazards, heavy towers, etc., achieve simple structure, save production costs, and improve the effect of deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

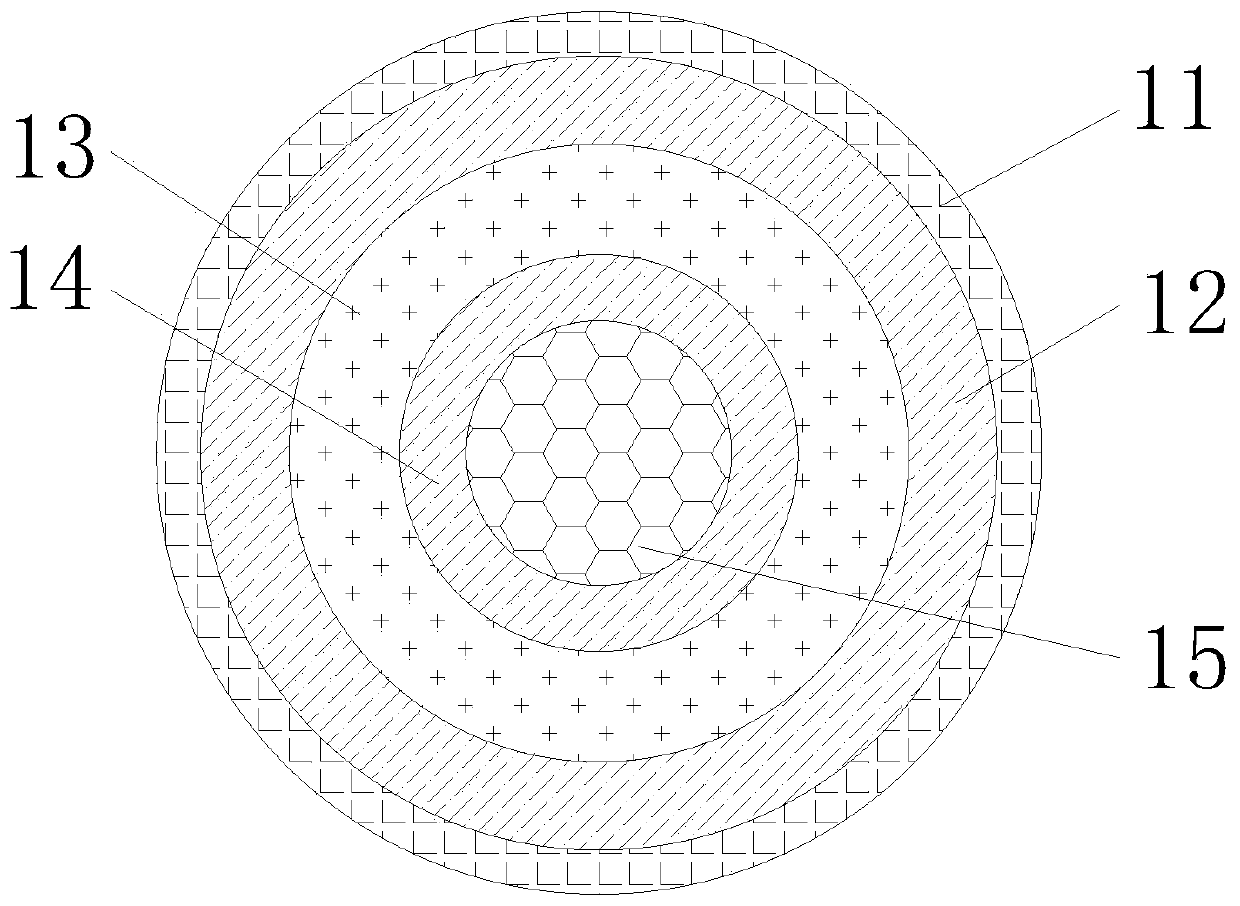

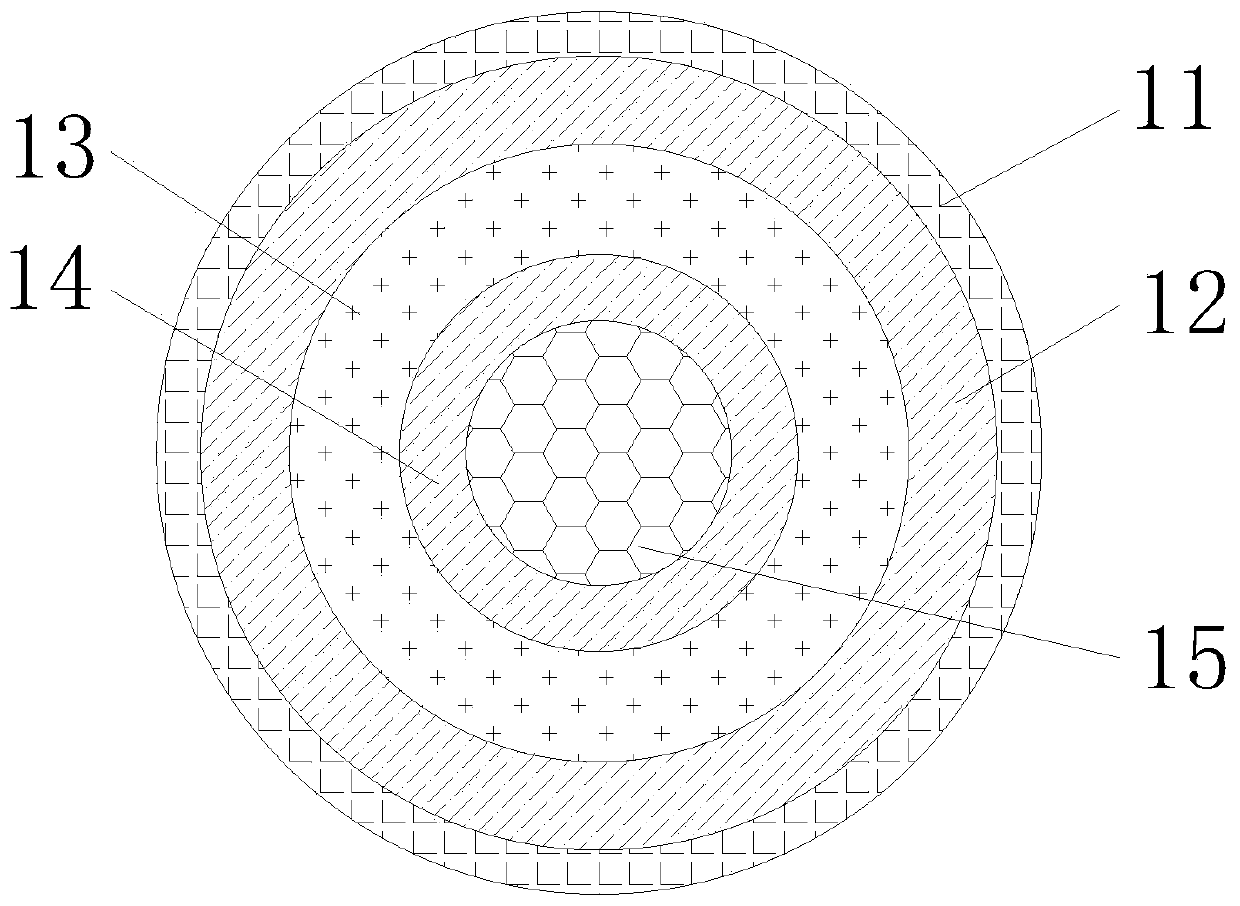

[0036] Such as Figure 1-2 As shown, a fiber-wound power pole tower includes a power pole main body, the power pole main body includes a multi-layer fiber winding layer, from the outside to the inside, it includes a surface functional layer 11, a first fiber winding layer 12, and a mixed material layer. 13 and the second fiber winding layer 14. The first fiber winding layer 12 is made of glass fiber material. The wound glass fiber is heated and solidified to form a fiber winding layer. Compared with the concrete material and the steel material power tower, In addition to its lighter weight, the fiber winding layer has strong toughness and meets the performance requirements of power transmission lines for power towers.

[0037] The mixed material layer 13 is disposed on the inner side of the first filament winding layer 12 and includes quartz sand and resin material, the ratio of the quartz sand to the resin material is 1-3:1, and the resin material is epoxy resin , Unsaturated p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com