Linear multi-station wine yeast pressing experiment table

A multi-station, test-bed technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems that the production line koji-making equipment cannot set and control multi-variable parameters, and no special experimental equipment, etc., to reduce the scrap rate and recovery rate, the effect of ensuring the quality of koji making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

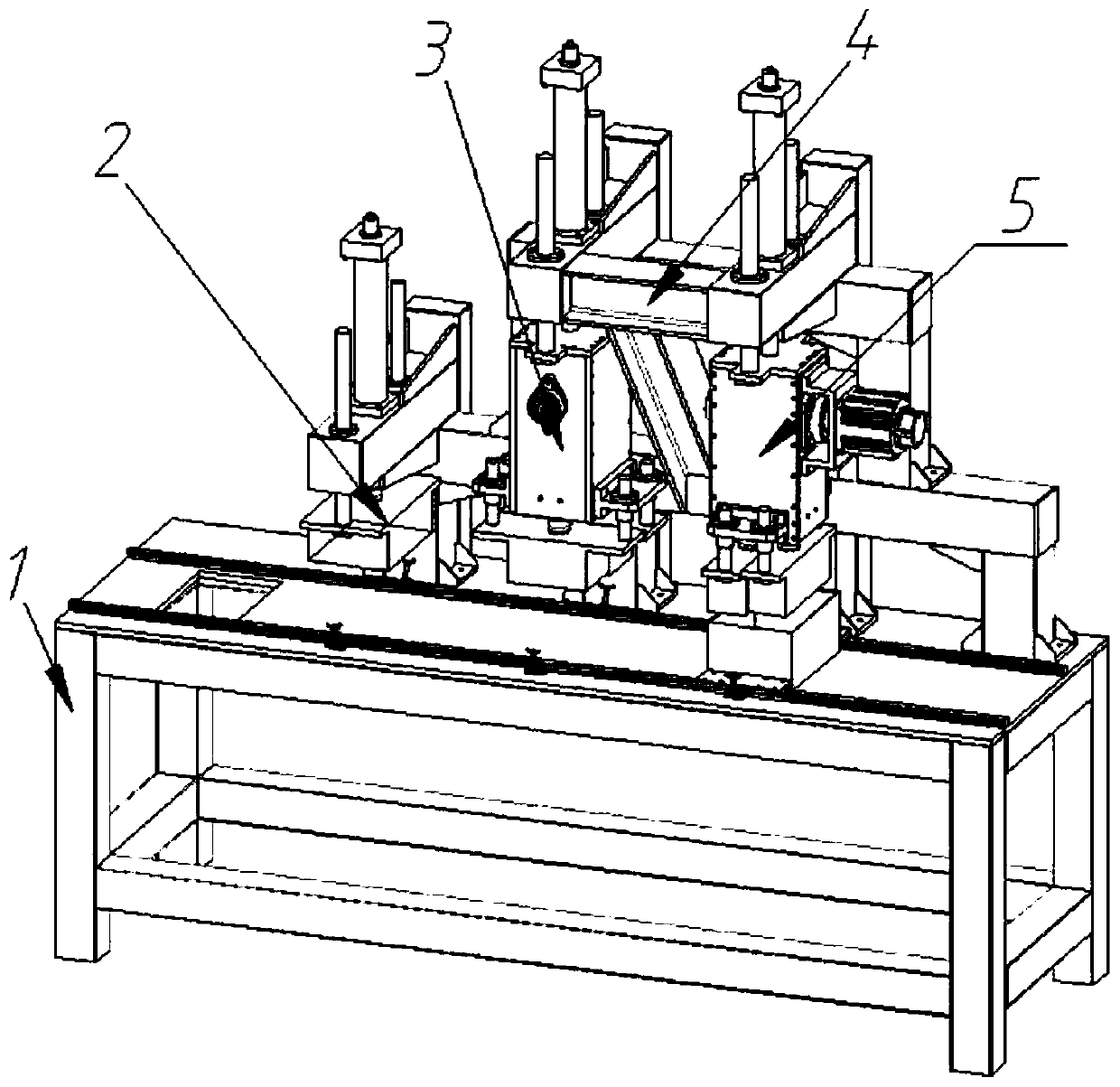

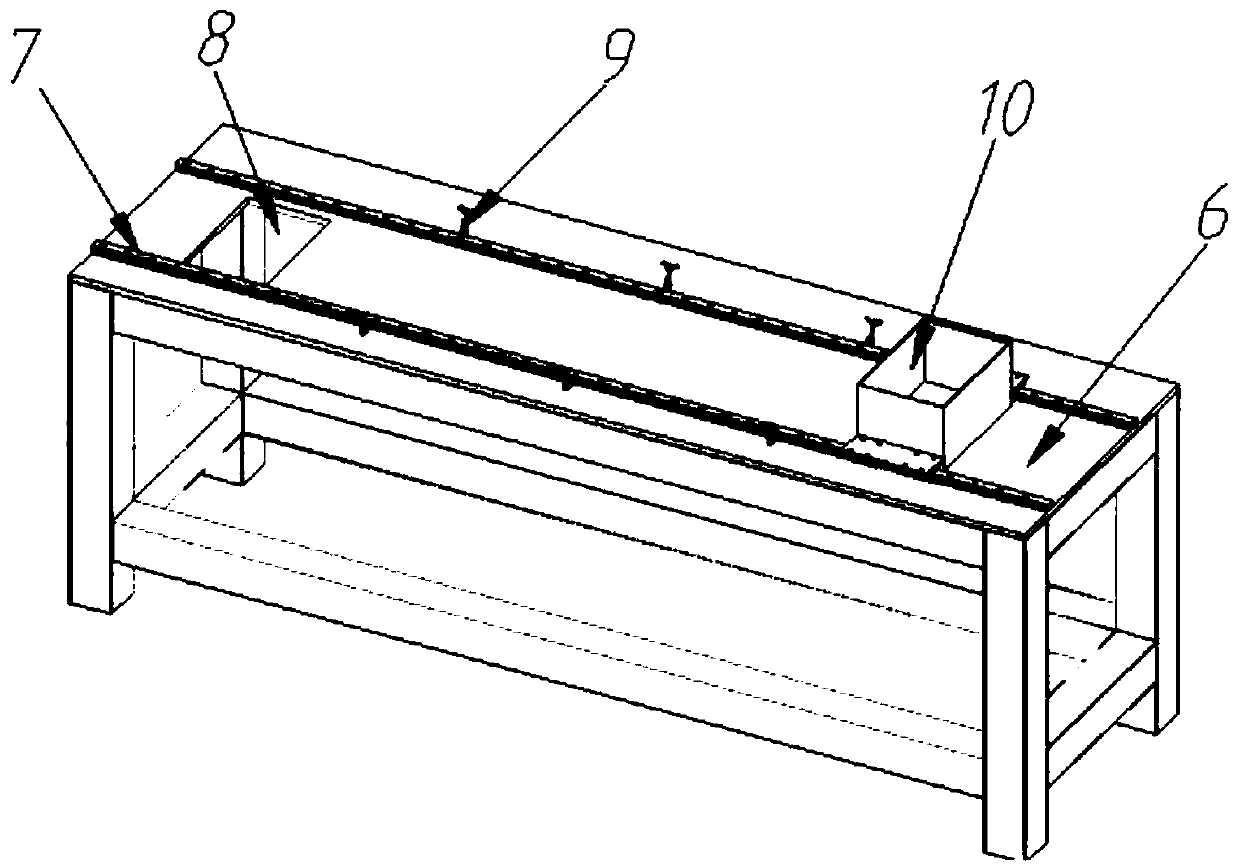

[0026] Such as figure 1 and figure 2 As shown, a linear multi-station buckling test bench includes a frame (1) with a track (7), a demoulding port (8) is provided on the frame table (6) and a set along the track Several positioning screw rods (9), the positioning screw rods are used to ensure the precise positioning of each station hammer head and mold box. A cantilever beam (4) is arranged on the rack table on one side of the track (7), on which a longitudinal beating mechanism (5), a transverse beating mechanism (3) and a forming mechanism are sequentially fixed along the direction of the track (2), the track (7) is provided with a curved block module box (10) capable of sliding along the track; the cantilever beam must have reinforcement ribs of sufficient strength to ensure that the cantilever beam has sufficient bending resistance.

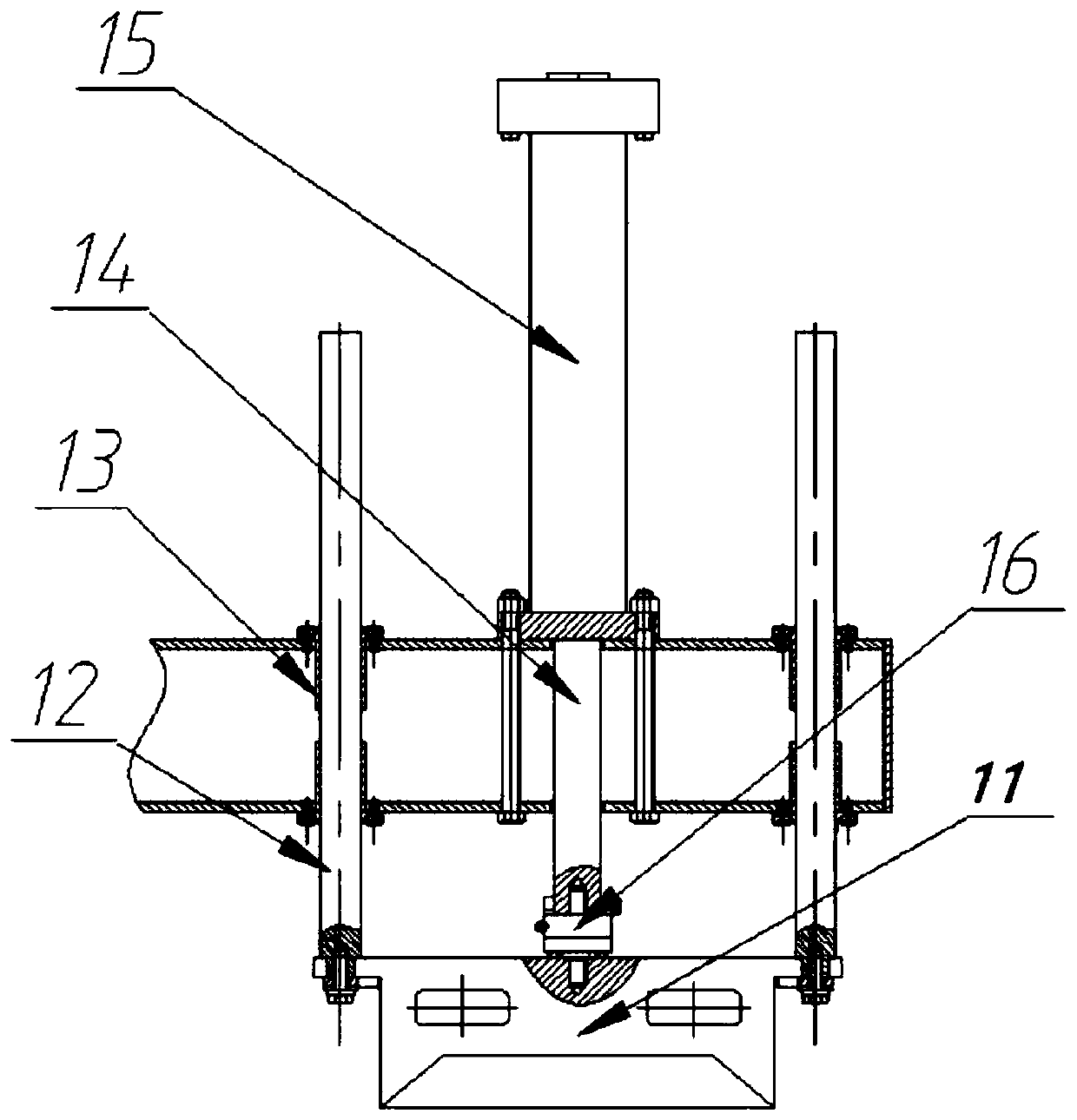

[0027] Such as image 3 and Figure 4 As shown, the forming mechanism (2) includes a No. 1 hydraulic cylinder (15) fixed on the cantile...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap