Method for synthesizing salicylonitrile by adopting microchannel reactor

A micro-channel reactor, o-hydroxybenzonitrile technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid nitrile, etc., can solve problems such as unseen o-hydroxybenzonitrile, and achieve continuous production mode Chemical, high quality, improved safety and environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

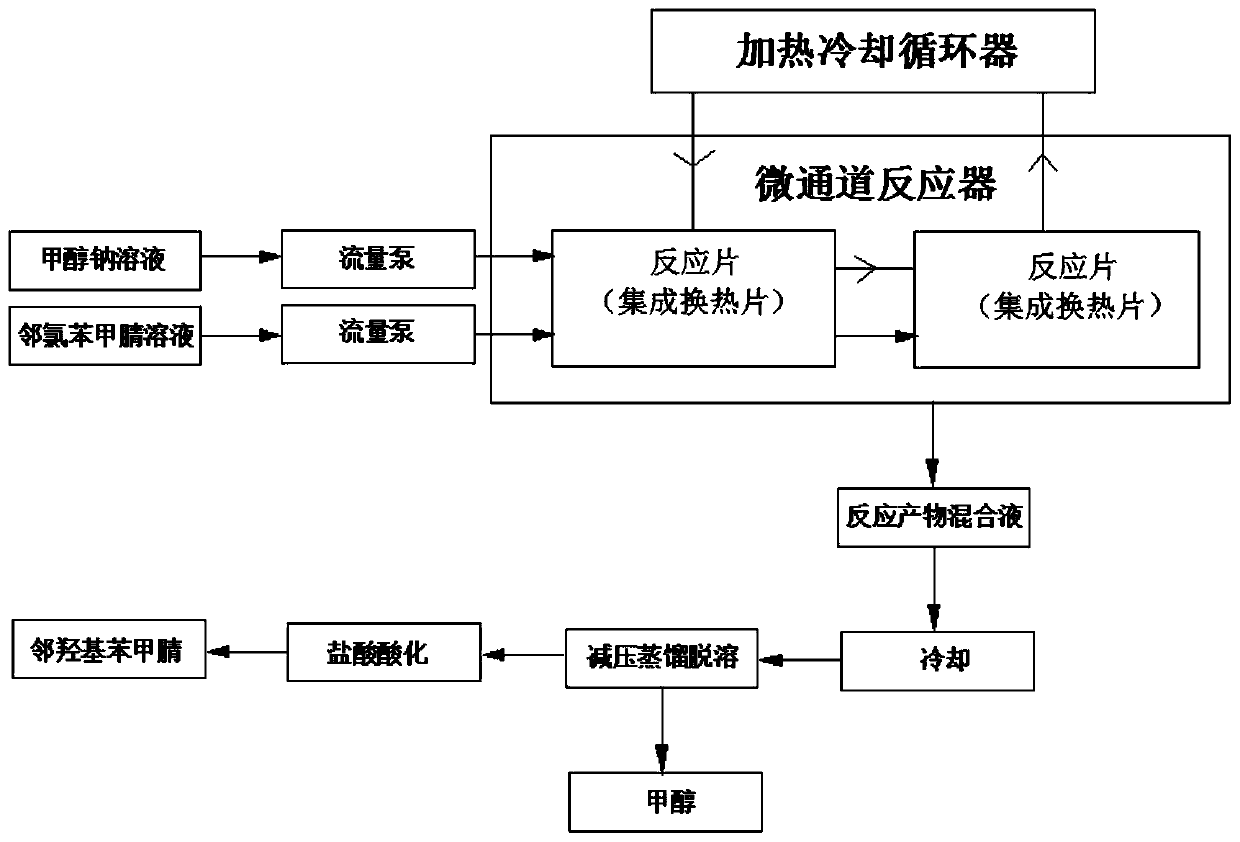

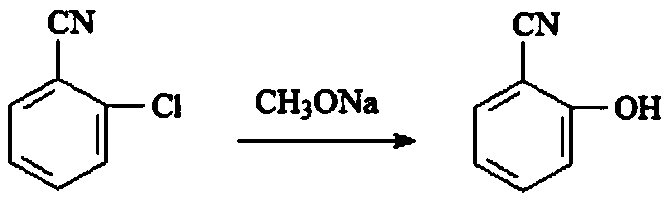

[0027] The method for synthesizing o-hydroxybenzonitrile using a microchannel reactor of the present invention is to synthesize o-hydroxybenzonitrile with sodium methylate and o-chlorobenzonitrile as reactant raw materials, comprising the following steps:

[0028] S1: Pretreatment of reactants, respectively dissolving 48g (0.88mol) of sodium methoxide and 60g (0.44mol) of o-chlorobenzonitrile in anhydrous methanol to form a sodium methoxide solution with a mass concentration of 40% and a mass concentration of 40% o-chlorobenzonitrile solution;

[0029] S2: The setting of the reaction conditions of the microchannel reactor, the heat exchange sheet integrated with the reaction sheet in the microchannel reactor is connected to the external heating and cooling circulator, and the heat exchange medium in the heat exchange sheet is heat transfer oil, through The heating and cooling circulator set the reaction temperature of the microchannel reactor to 110°C, and set the pressure of ...

Embodiment 2

[0033] The method for synthesizing o-hydroxybenzonitrile using a microchannel reactor of the present invention is to synthesize o-hydroxybenzonitrile with sodium methylate and o-chlorobenzonitrile as reactant raw materials, comprising the following steps:

[0034] S1: Pretreatment of reactants, respectively dissolving 120g (2.22mol) of sodium methoxide and 100g (0.73mol) of o-chlorobenzonitrile in anhydrous methanol to form a sodium methoxide solution with a mass concentration of 30% and a mass concentration of 50% o-chlorobenzonitrile solution;

[0035] S2: The setting of the reaction conditions of the microchannel reactor, the heat exchange sheet integrated with the reaction sheet in the microchannel reactor is connected to the external heating and cooling circulator, and the heat exchange medium in the heat exchange sheet is heat transfer oil, through The heating and cooling circulator sets the reaction temperature of the microchannel reactor to 140°C, and sets the pressure...

Embodiment 3

[0039] The method for synthesizing o-hydroxybenzonitrile using a microchannel reactor of the present invention is to synthesize o-hydroxybenzonitrile with sodium methylate and o-chlorobenzonitrile as reactant raw materials, comprising the following steps:

[0040] S1: Reactant pretreatment, respectively dissolving 40g (0.74mol) of sodium methoxide and 100g (0.73mol) of o-chlorobenzonitrile in anhydrous methanol to form a sodium methoxide solution with a mass concentration of 5% and a mass concentration of 20% o-chlorobenzonitrile solution;

[0041] S2: The setting of the reaction conditions of the microchannel reactor, the heat exchange sheet integrated with the reaction sheet in the microchannel reactor is connected to the external heating and cooling circulator, and the heat exchange medium in the heat exchange sheet is heat transfer oil, through The heating and cooling circulator sets the reaction temperature of the microchannel reactor to 200°C, and sets the pressure of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com