Co-doped nanometer zinc oxide powder body and preparation method thereof

A nano-zinc oxide powder and co-doping technology, which is applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the difficulty of achieving uniform mixing at the nanoscale, affecting the stability of sputtering glow, and uneven conductivity of the target In order to achieve the effects of easy large-scale industrial production, precise and controllable reaction conditions, and easy pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

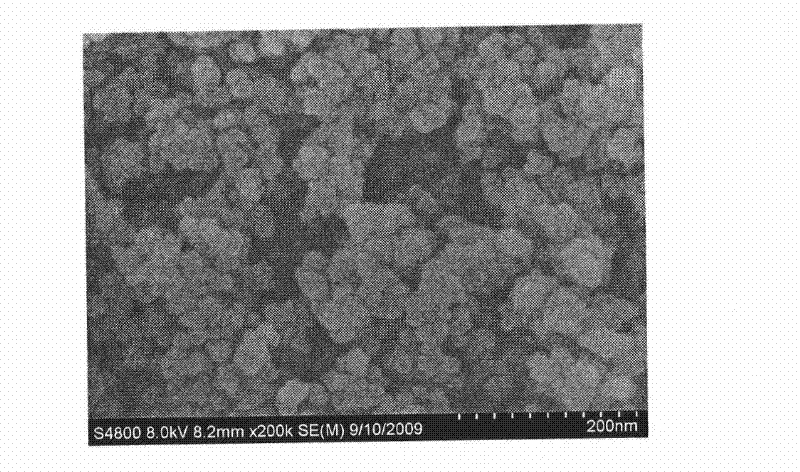

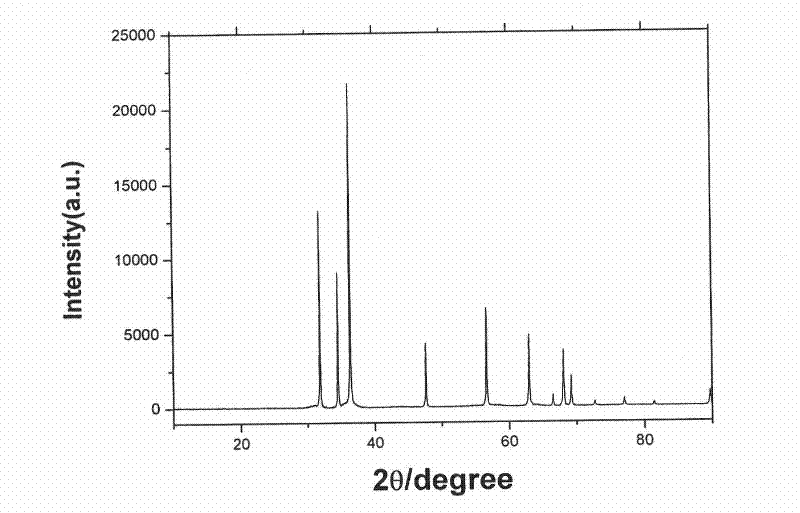

Embodiment 1

[0028] Add titanium tetrachloride dropwise to deionized water at 5°C to make a 1mol / L solution; dissolve zinc nitrate and aluminum nitrate in deionized water at room temperature to make a 1mol / L aqueous solution, wherein the molar ratio between aluminum ions and zinc ions The ratio is 9:73; the above two solutions are mixed and an appropriate amount of deionized water is added to form a salt solution with an ion concentration of 0.5mol / L, wherein the molar ratio between titanium ions, aluminum ions, and zinc ions is 18: 9: 73; under stirring at 400 rev / min, the above-mentioned salt solution was added dropwise to the reaction vessel pre-installed with deionized water through different dropping channels at a rate of 50mL / min and 1mol / L ammonia solution, During the dropping process, adjust the dropping rate of the ammonia solution so that the pH value of the solution in the reaction vessel is kept between 7.0 and 7.2, and the solution temperature is 25°C to obtain a co-precipitate...

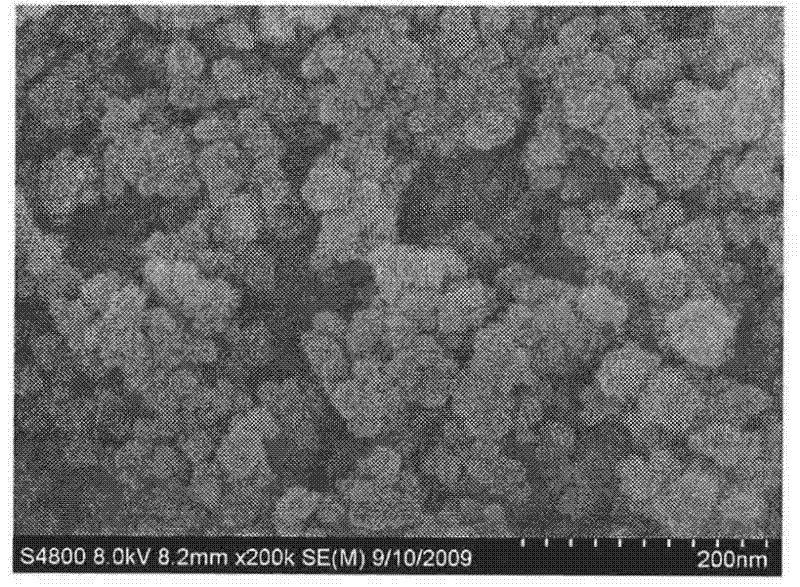

Embodiment 2

[0031]Add titanium tetrachloride dropwise to deionized water at 0°C to make a 3mol / L solution; dissolve zinc nitrate and aluminum nitrate in deionized water at room temperature to make a 3mol / L aqueous solution, in which the molar ratio between aluminum ions and zinc ions The ratio is 1:44; mix the above two solutions and add an appropriate amount of deionized water to form a salt solution with an ion concentration of 1mol / L, wherein the molar ratio between titanium ions, aluminum ions, and zinc ions is 10:2:88 ; Under stirring at 500 rpm, the above-mentioned salt solution is added dropwise to the reaction vessel pre-installed with deionized water at a rate of 30mL / min and the ammonia solution of 3mol / L through different dropping channels. Adjust the drop rate of the ammonia solution in the middle to keep the pH value of the solution in the reaction vessel between 8.0 and 8.2, and the solution temperature is 30°C to obtain the coprecipitated product; after aging the precipitate...

Embodiment 3

[0034] Add titanium tetrachloride dropwise to deionized water at 0°C to make a 5mol / L solution; dissolve zinc nitrate and aluminum nitrate in deionized water at room temperature to make a 6mol / L aqueous solution, in which the molar ratio between aluminum ions and zinc ions The ratio is 9:82; the above two solutions are mixed and an appropriate amount of deionized water is added to form a salt solution with an ion concentration of 2mol / L, wherein the molar ratio between titanium ions, aluminum ions, and zinc ions is 9:9 : 82; under the stirring of 600 revs / min, with the ammonia solution of above-mentioned salt solution with the speed of 40mL / min and 3mol / L through different drop-adding passages simultaneously dropwise in the reaction container that deionized water is housed in advance, drop During the addition process, adjust the dripping rate of the ammonia solution to keep the pH value of the solution in the reaction vessel between 7.5 and 7.7, and the solution temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com