Bismuth ferrite material with perovskite-like structure as well as preparation method and application of bismuth ferrite material

A perovskite structure, bismuth ferrite technology, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve problems such as difficult industrial production, low photoelectric conversion rate, and poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

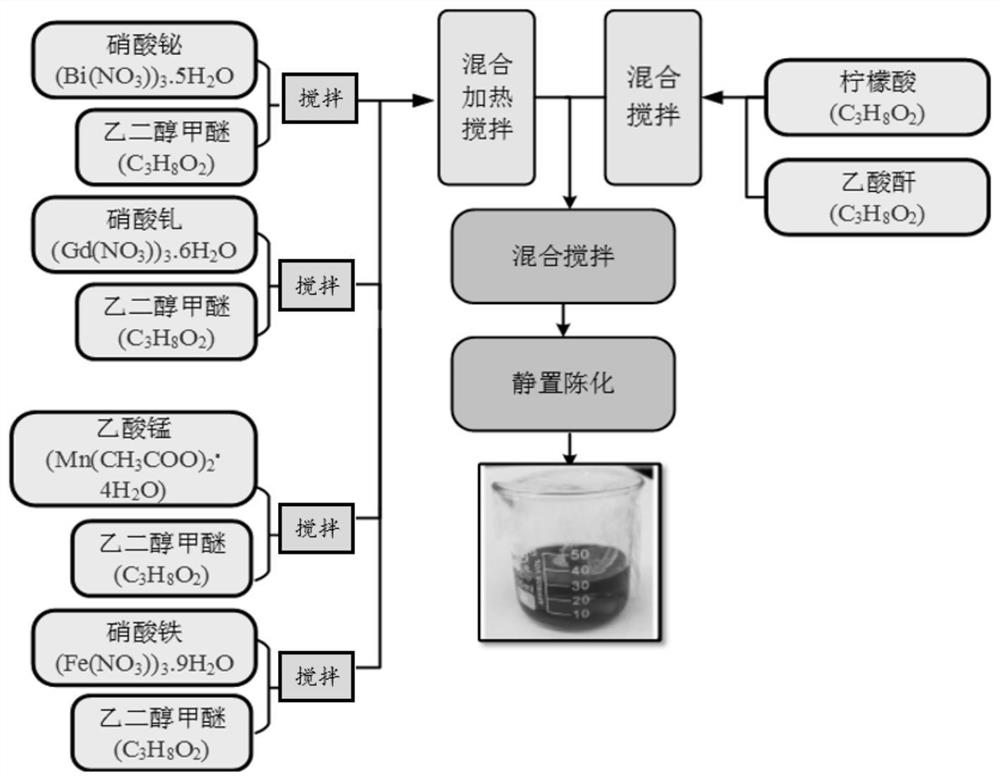

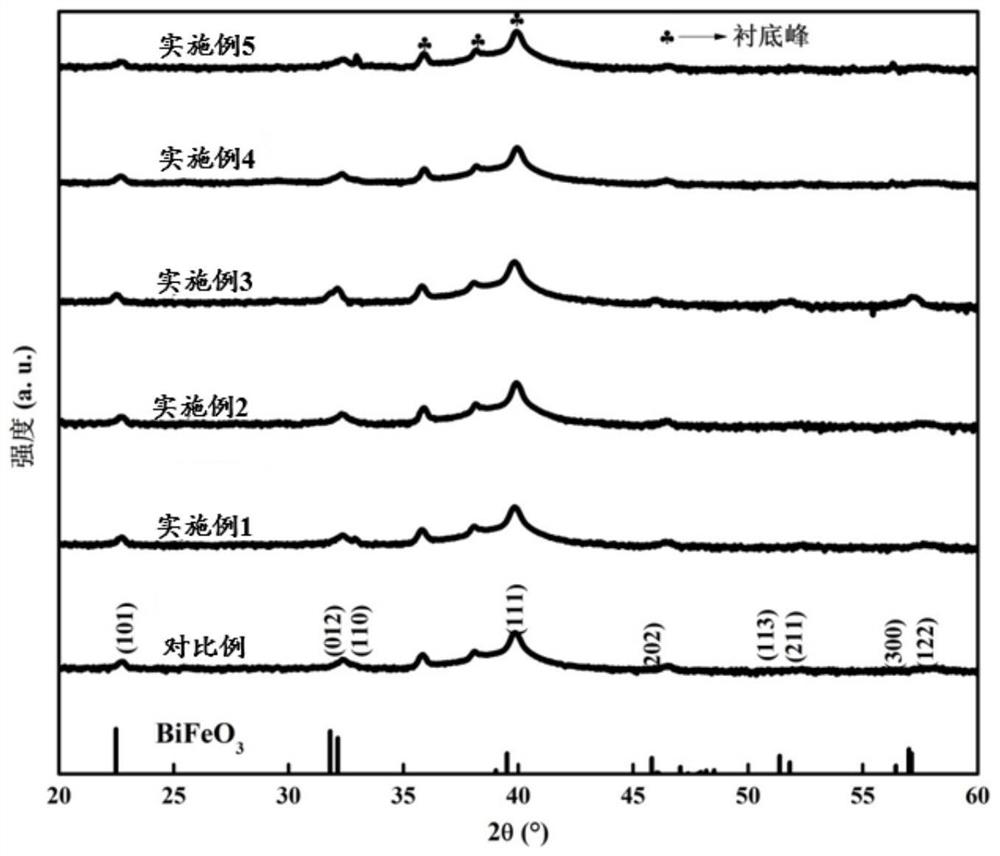

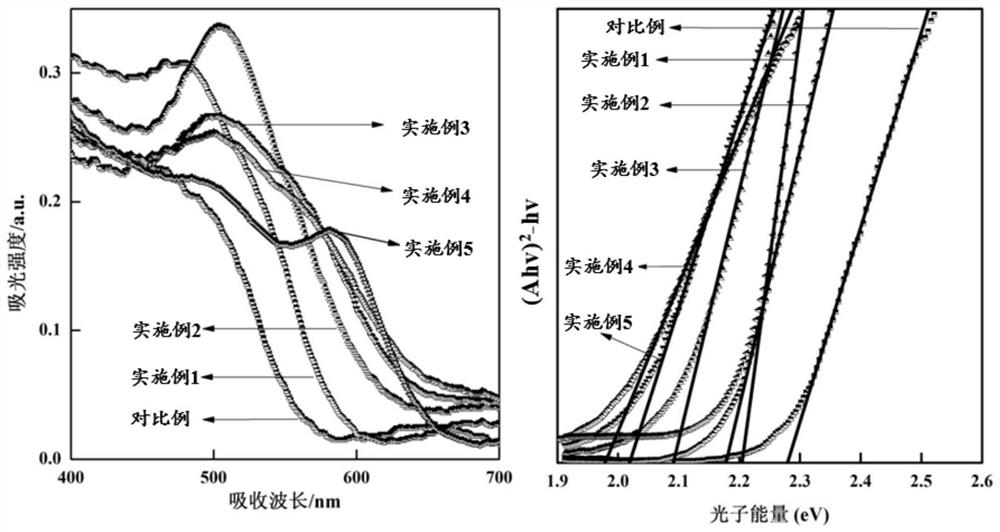

[0057] Embodiment 1 class perovskite structure bismuth ferrite material (Bi 1-x Gd x Fe 1-y mn y o 3 Preparation of x=0.15y=0)

[0058] (1) Precursor preparation: 8.55 mmol of analytically pure bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), 1.35mmol gadolinium nitrate (Gd(NO 3 ) 3 ·6H 2 O) were dissolved in 5mL ethylene glycol methyl ether (C 3 h 8 o 2 ), obtain the ethylene glycol methyl ether solution (1.71mol / L) of bismuth nitrate and the ethylene glycol methyl ether solution (0.27mol / L) of gadolinium nitrate, and the ethylene glycol methyl ether solution of bismuth nitrate and gadolinium nitrate The ethylene glycol methyl ether solution is mixed to obtain the ethylene glycol methyl ether mixed solution A (0.99mol / L). Then 9 mmol of ferric nitrate was dissolved in 5 mL of ethylene glycol methyl ether to obtain a solution B of ferric nitrate in ethylene glycol methyl ether (1.8 mol / L). Subsequently, the ethylene glycol methyl ether mixture A and the ethylene glycol me...

Embodiment 2

[0060] Embodiment 2 class perovskite structure bismuth ferrite material (Bi 1-x Gd x Fe 1-y mn y o 3 Preparation of x=0.15y=0.04)

[0061] (1) Precursor preparation: 8.55 mmol of analytically pure bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), 1.35mmol gadolinium nitrate (Gd(NO 3 ) 3 ·6H 2 O) were dissolved in 5mL ethylene glycol methyl ether (C 3 h 8 o 2), obtain the ethylene glycol methyl ether solution (1.71mol / L) of bismuth nitrate and the ethylene glycol methyl ether solution (0.27mol / L) of gadolinium nitrate, and the ethylene glycol methyl ether solution of bismuth nitrate and gadolinium nitrate The ethylene glycol methyl ether solution is mixed to obtain the ethylene glycol methyl ether mixed solution A (0.99mol / L). Then 8.64mmol of ferric nitrate and 0.36mmol of manganese acetate were dissolved in 5mL of ethylene glycol methyl ether to obtain a ethylene glycol methyl ether solution of ferric nitrate (1.728mol / L) and a ethylene glycol methyl ether solution of mang...

Embodiment 3

[0063] Embodiment 3 class perovskite structure bismuth ferrite material (Bi 1-x Gd x Fe 1-y mn y o 3 x=0.15y=0.08) preparation

[0064] (1) Precursor preparation: 8.55 mmol of analytically pure bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O), 1.35mmol gadolinium nitrate (Gd(NO 3 ) 3 ·6H 2 O) were dissolved in 5mL ethylene glycol methyl ether (C 3 h 8 o 2 ), obtain the ethylene glycol methyl ether solution (1.71mol / L) of bismuth nitrate and the ethylene glycol methyl ether solution (0.27mol / L) of gadolinium nitrate, and the ethylene glycol methyl ether solution of bismuth nitrate and gadolinium nitrate The ethylene glycol methyl ether solution is mixed to obtain the ethylene glycol methyl ether mixed solution A (0.99mol / L). Then 8.25mmol ferric nitrate and 0.7mmol manganese acetate were dissolved in 5mL of ethylene glycol methyl ether respectively to obtain a ethylene glycol methyl ether solution (1.65mol / L) of ferric nitrate and a ethylene glycol methyl ether solution of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com