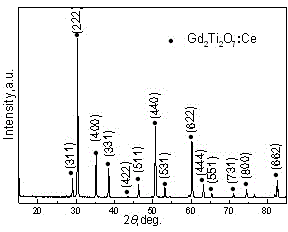

Method for preparing gd2ti2o7:ce nano-luminescent powder by reverse co-precipitation

A reverse co-precipitation, luminescent powder technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of uneven product particle size, complex preparation process, high cost, accurate and controllable reaction conditions, and wide application Prospect, the effect of short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The material selection of the present invention: experimental raw material is Gd 2 o 3 (99.99%), Ce(NO 3 ) 3 (99.9%), Ti(SO 4 ) 2 , ammonia, nitric acid, absolute ethanol and sodium dodecylbenzenesulfonate (SDBS) are all analytical reagents, and distilled water is secondary water. The above reagents were not purified.

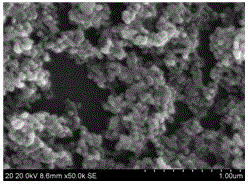

[0022] The preparation process of the present invention: weigh Gd according to the precise stoichiometric ratio 2 o 3 , Ti(SO 4 ) 2 and Ce(NO 3 ) 3 . Will Gd 2 o 3 Dissolved in excess dilute nitric acid solution to obtain Gd(NO 3 ) 3 solution; then Ti(SO 4 ) 2 Dissolve in water and then dissolve in the above solution to prepare a mother salt solution with a metal cation concentration of 0.08mol / L. Weigh 0.3% (mol fraction) of Ce(NO 3 ) 3 Dissolve in the mother salt solution and stir well until the mixture is uniform. Prepare 1mol / L ammonia water as the precipitant, weigh 1wt%~2wt% dispersant SDBS, dissolve it in the precipitant ammon...

Embodiment 2

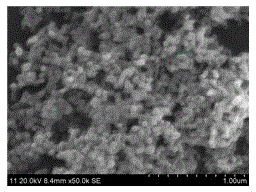

[0024] Mother salt concentration is 0.06mol / L, and other conditions are as embodiment 1, and the morphology of gained sample is as follows image 3 As shown in the middle SEM, the shape of the sample is basically spherical, the particle size is about 60nm, the dispersion of the sample is average, and there is agglomeration phenomenon.

Embodiment 3

[0026] Mother salt concentration is 0.10mol / L, and other conditions are as embodiment 1, and the morphology of gained sample is as follows Figure 4 As shown in the middle SEM, the shape of the sample is basically spherical, the particle size distribution is uneven, and the agglomeration phenomenon is obvious.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com