Deep tamping tube and construction method thereof

A technology of deep ramming and ramming pipes, which is applied in the direction of foundation structure engineering, soil protection, sheet pile walls, etc., can solve the problems of limited processing depth and high construction noise, and achieve the purpose of reducing noise impact, improving soil strength, and good compaction The effect of dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

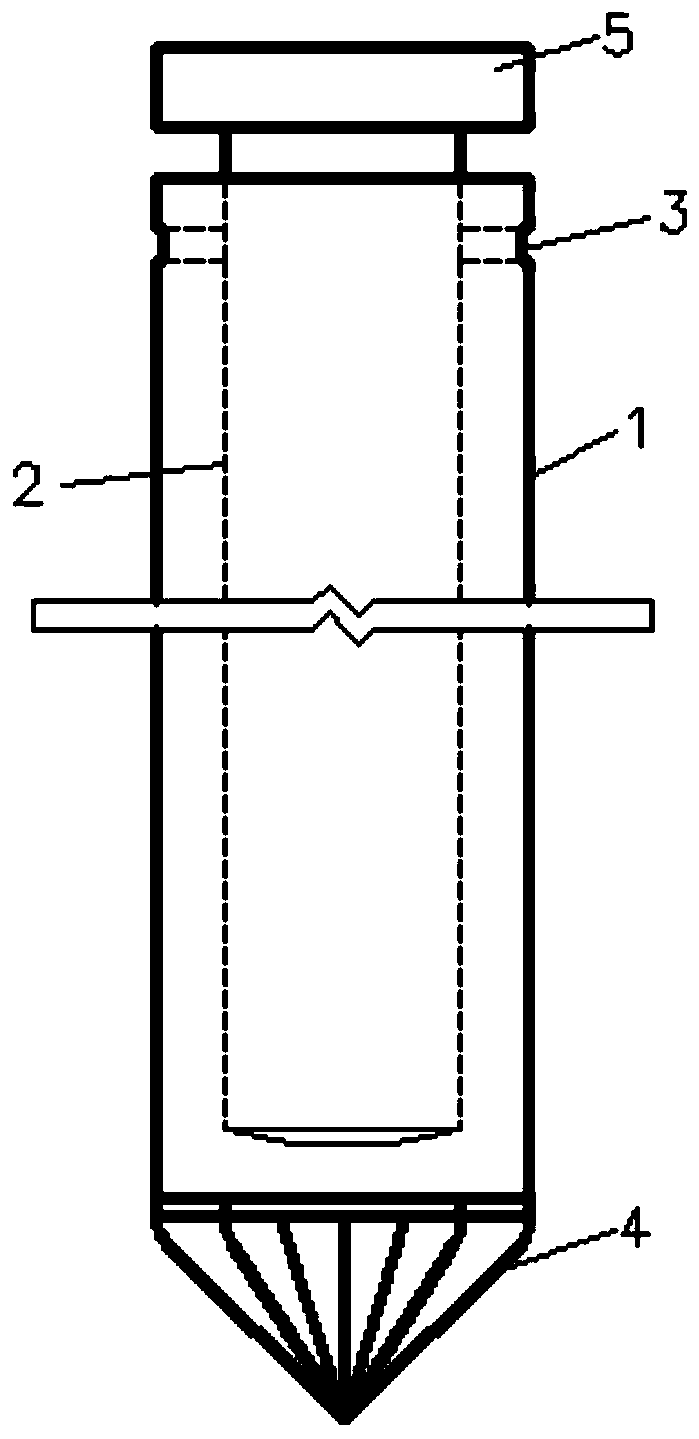

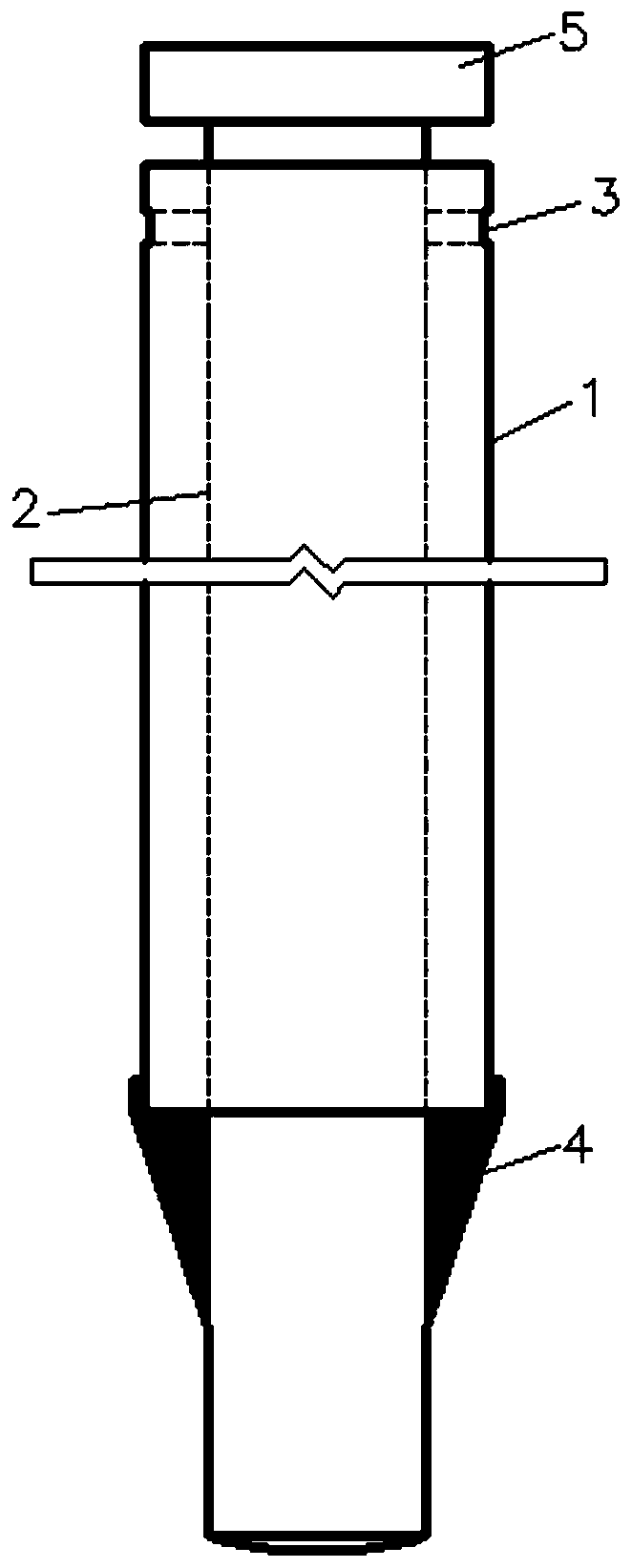

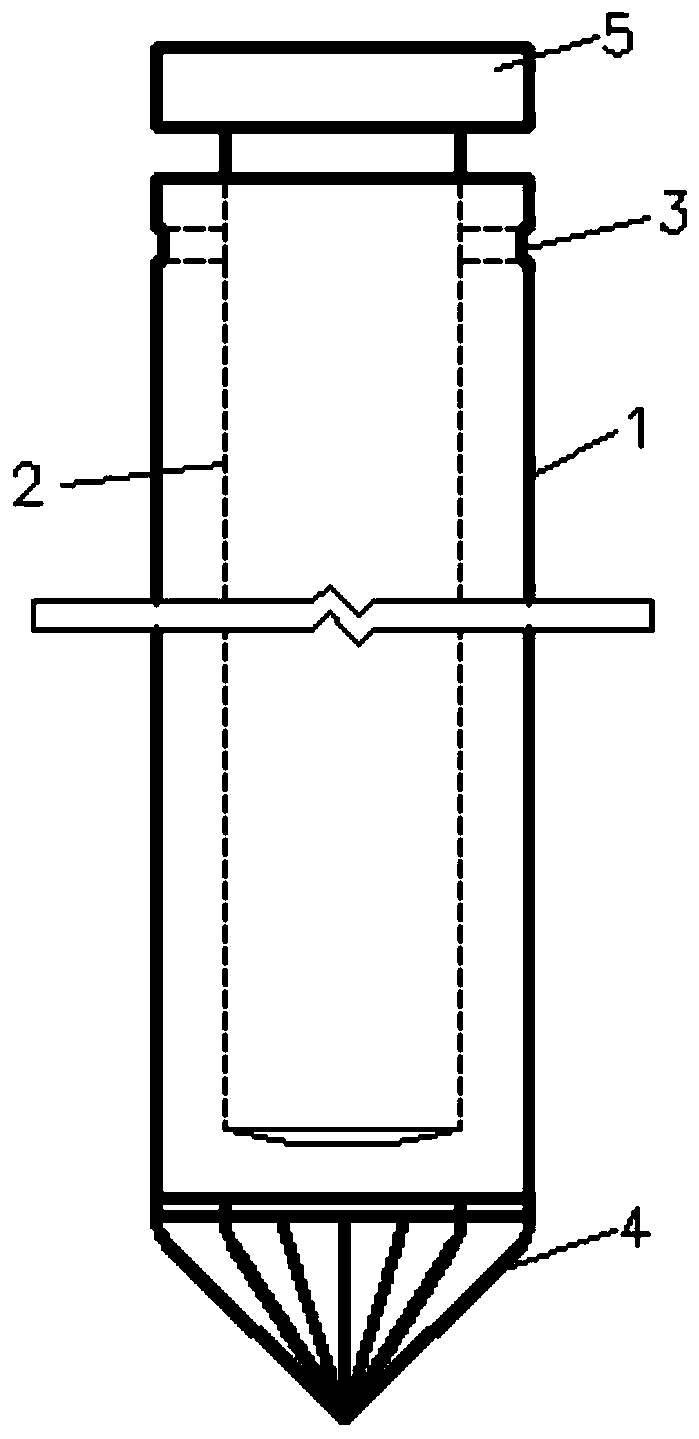

[0023] Such as figure 1 As shown, a deep rammed pipe includes an external protective casing 1 and several sections of rammed pipes 2 that can be built into the protective casing 1 and can be freely assembled. The square hole 3 where the hydraulic press is clamped, the lower end is connected to the valve spud shoe 4, the specific size and material can be referred to as follows: the outer diameter of the steel protective sleeve 1 is 0.4-1.2m, the height of the upper square hole 3 is 8-10cm, and the projection width is 12 ~ 15cm. In this way, the quick connection with the hydraulic press can be realized, and the working efficiency can be effectively improved. The length of each section of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com