Mechanized construction method of large underground spent fuel disposal repositories

A construction method and technology for spent fuel, applied in underground chambers, earthwork drilling, shaft equipment, etc., can solve the problems of low level of mechanized construction, long construction time, low utilization rate of underground space, etc., and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

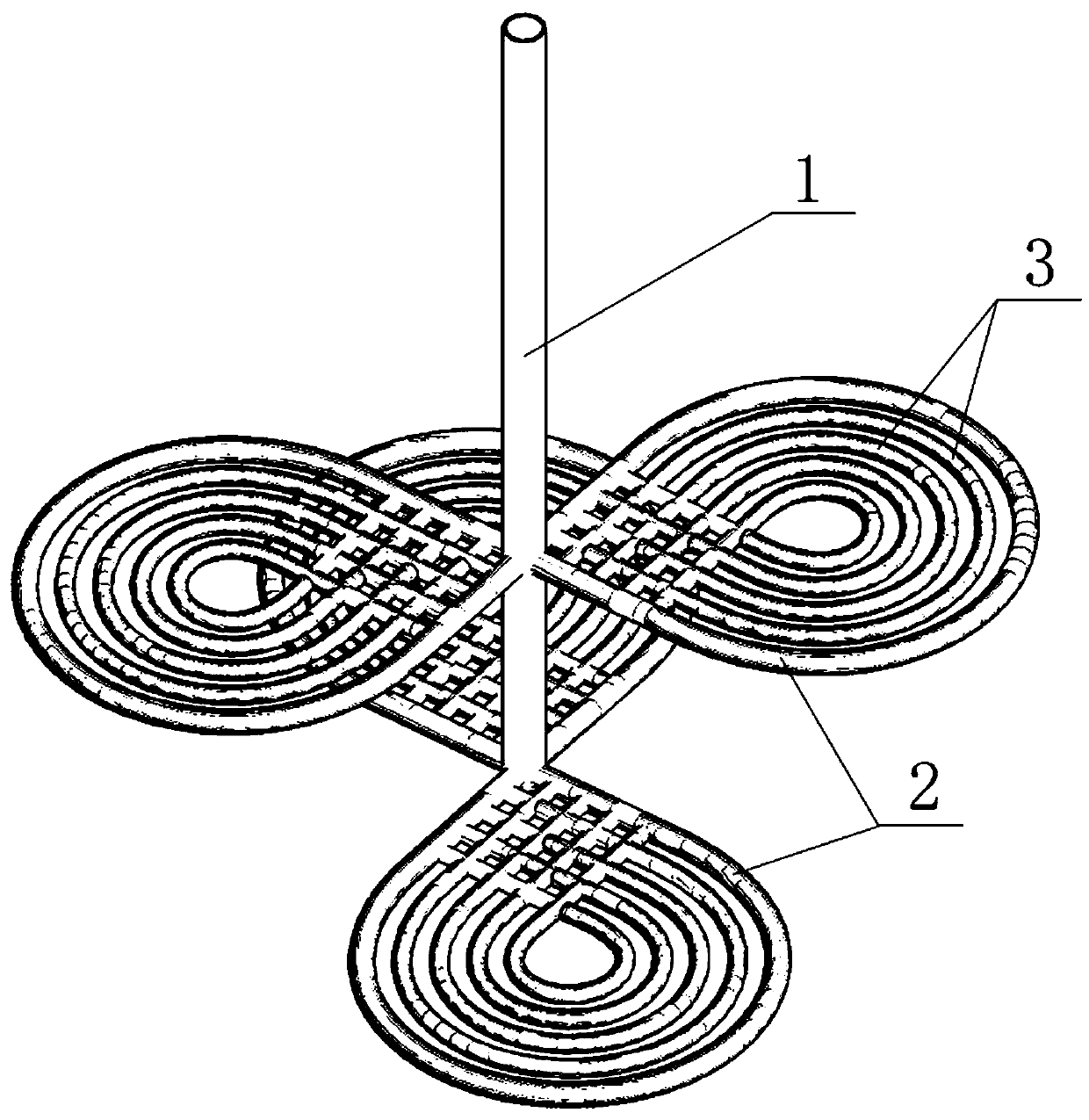

[0034] Embodiment 1: as figure 1 As shown, a large-scale underground spent fuel repository mechanized construction method includes the following steps:

[0035] S1, first carry out shaft 1 construction, and use shaft drilling rigs or mechanical + blasting excavation to construct the shaft until the design depth is reached. For the case where a multi-layer repository needs to be built, several holes are reserved around the shaft 1 on each floor;

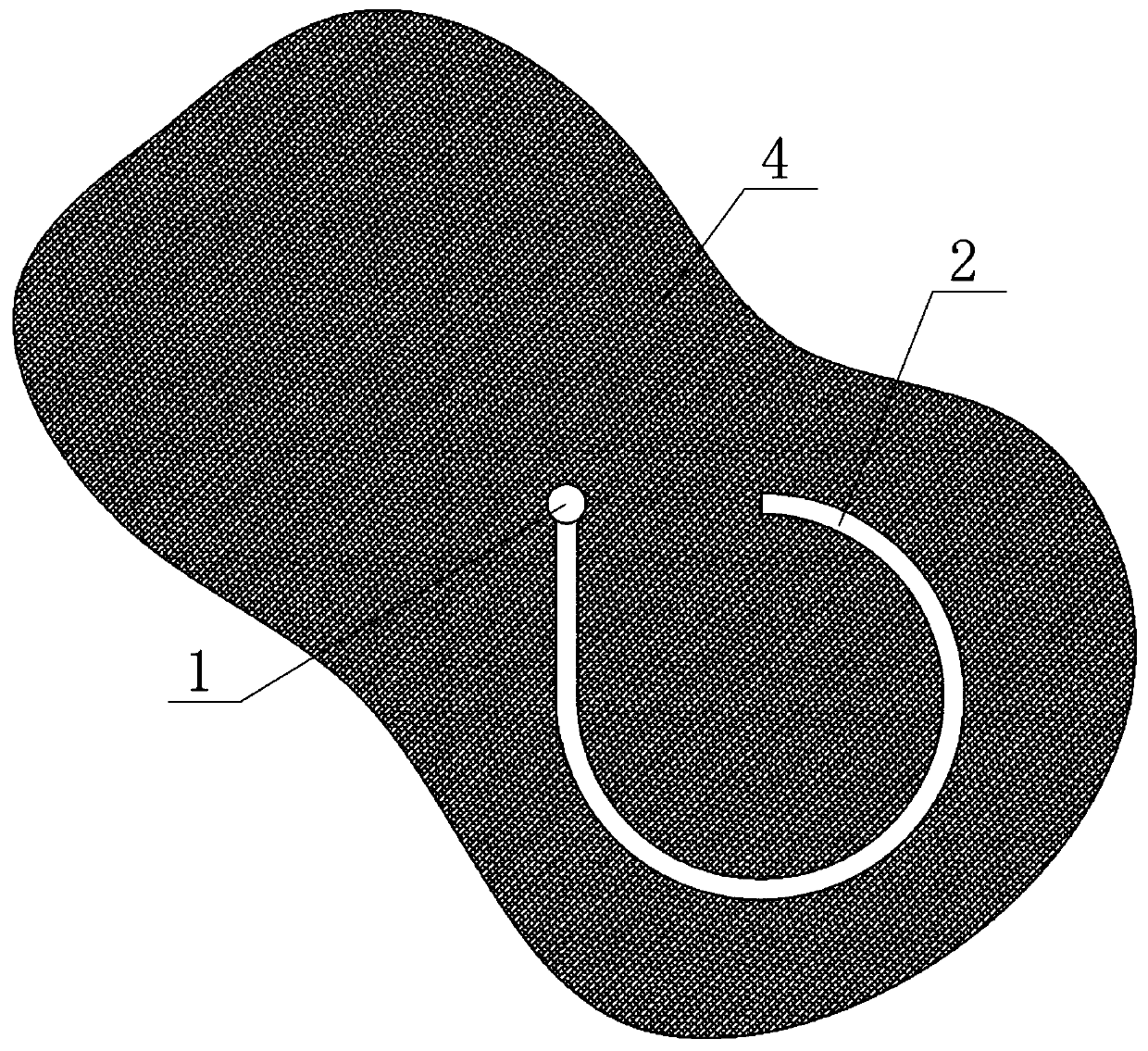

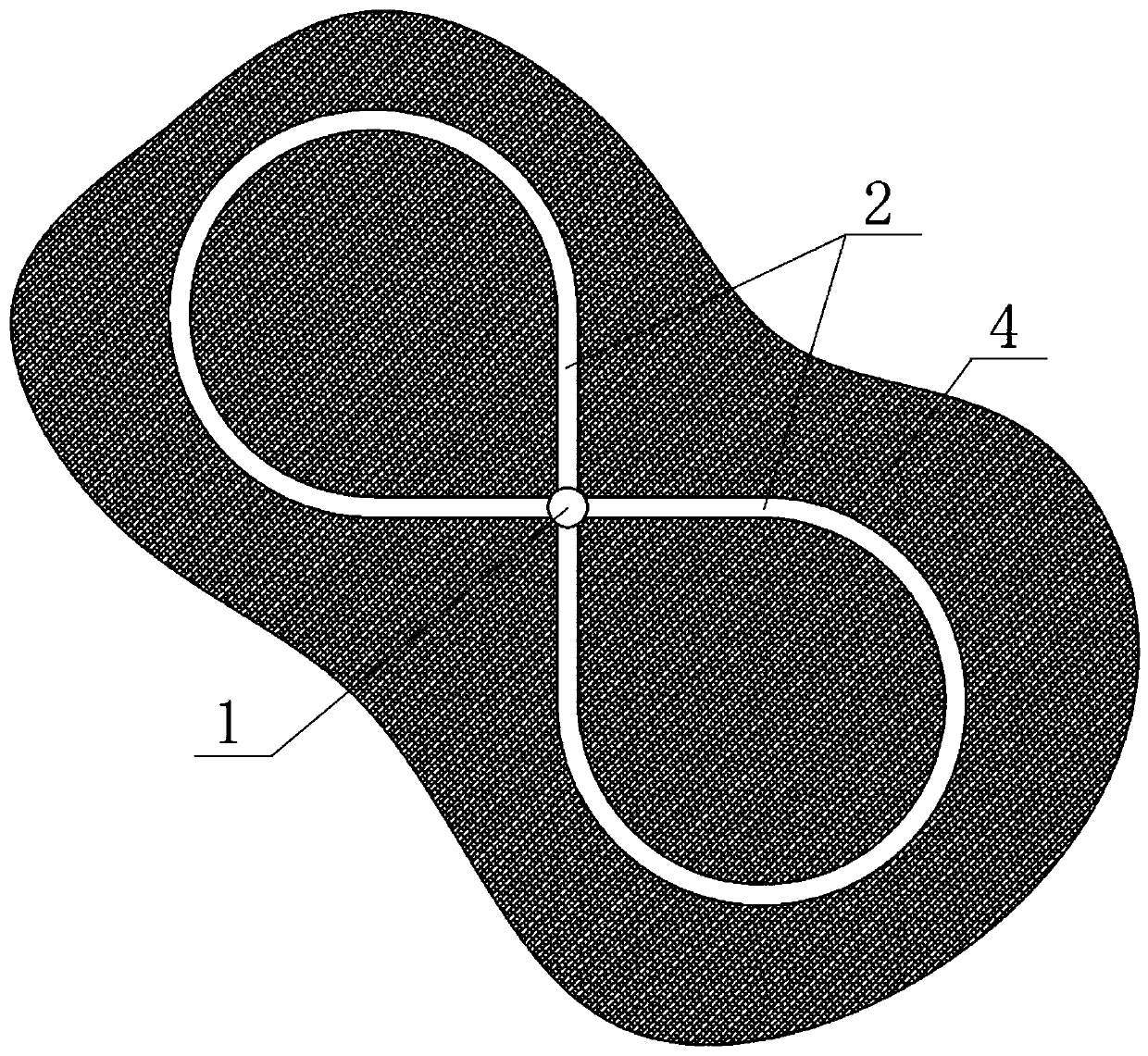

[0036] S2, such as figure 2 and image 3 As shown, the construction of the outer ring 2 is carried out subsequently, and a temporary platform is built on the holes reserved around the shaft 1. The starting end and the receiving end of the main shield machine are set in the shaft 1, and the starting end of the main shield machine The launching direction is perpendicular to the receiving direction of the receiving end of the main shield machine. Hoist the main shield machine from the ground to the temporary platform, adjust the posit...

Embodiment 2

[0043] Embodiment 2: A mechanized construction method for a large-scale underground spent fuel repository. The small shield machine is perpendicular to the starting straight section of the outer ring 2 and the receiving straight section of the outer ring 2, that is, the small shield machine has been specially designed, both It can meet the small radius turning, and can also meet the straight line section perpendicular to the outer ring starting line and the receiving line section of the outer ring. The starting and receiving of the small shield machine in a narrow space is convenient for the small shield machine to excavate the inner ring.

[0044] All the other structures and construction methods are the same as in Embodiment 1.

Embodiment 3

[0045] Embodiment 3: The mechanized construction method of a large-scale underground spent fuel repository. In the step S4, a small shield machine is hoisted into the outer ring 2 of the repository on both sides to excavate the inner ring 3, and the tunneling construction is carried out at the same time, which greatly improves Overall work efficiency and shorter construction period.

[0046] All the other structures and construction methods are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com