Automation krypton and xenon gas continuous bottle filling device

A bottle rinsing and gas technology, applied in gas/liquid distribution and storage, geometry/arrangement/size of container structure, fluid treatment, etc., can solve problems such as low bottle filling efficiency, potential safety hazards, and error-prone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

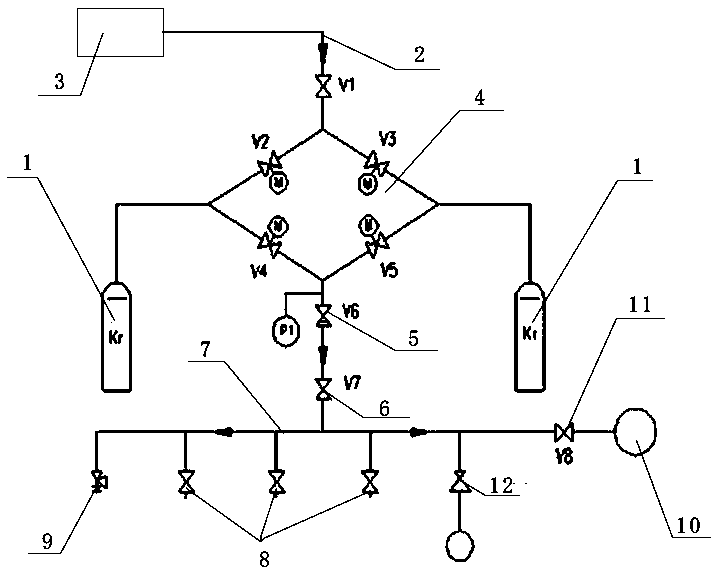

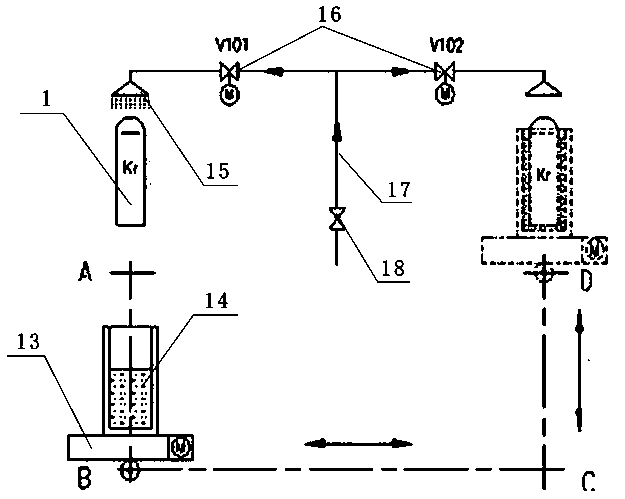

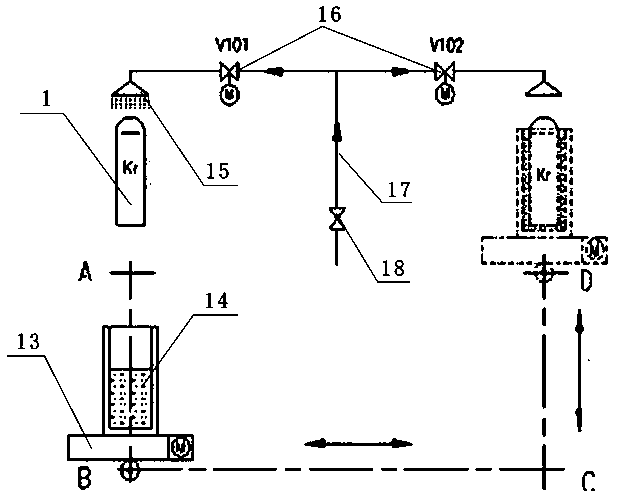

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: Figure 1-2 As shown, an automatic continuous rinsing device for krypton-xenon gas, which includes a storage device and a bottle rinsing device, is characterized in that the bottle rinsing device is composed of high-pressure gas cylinders 1 arranged on the left and right sides, and the high-pressure gas cylinders pass through pipelines 2 is connected to the cold box 3, and a diamond-shaped regulating valve 4 is arranged on the pipeline 2. The regulating valve 4 is connected to PLC control, and the bottom of the regulating valve 4 on the pipeline 2 is also provided with a check valve 5 and a cut-off valve in turn. The valve 6 is finally connected to the inflation pipeline 7 at the bottom, and the inflation pipeline 7 is provided with a bottle filling valve 8 and a safety valve 9, and is provided with an air extraction vacuum pump 10 on one side, and is provided between the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com