High-voltage electrode boiler

A high-voltage electrode and boiler technology, applied in the direction of electrode boilers, steam boilers, fluid heaters, etc., can solve the problems of arc discharge and easy breakdown medium, so as to reduce equipment damage, avoid arc discharge, and quickly adjust the load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

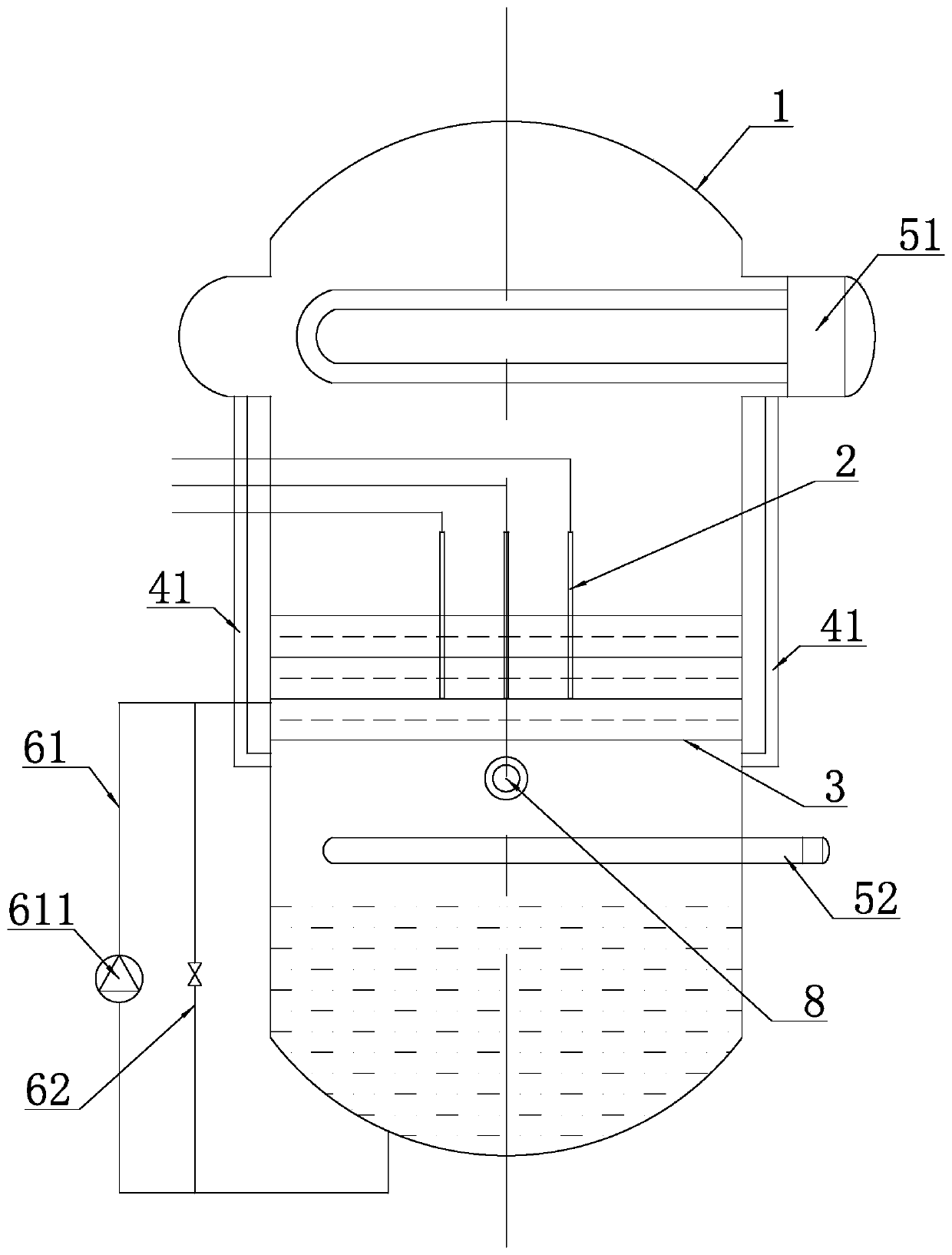

[0040] Such as figure 1 As shown, a high-voltage electrode boiler includes a vertical casing 1 filled with a certain amount of non-condensable gas. As a specific implementation, the non-condensable gas described in this embodiment is nitrogen. A partition 3 is arranged inside the housing 1, and the partition 3 divides the inner space of the housing 1 into an upper space and a lower space.

[0041] The first heat exchanger 51 and the electrode 2 are sequentially arranged in the upper space from top to bottom, and the first heat exchanger 51 and the electrode 2 are respectively fixedly connected to the casing 1 . Both the water inlet and the water outlet of the first heat exchanger 51 are located outside the casing 1 .

[0042] As a specific implementation, such as figure 1 As shown, in this embodiment, the casing of the first heat exchanger and the casing of the boiler are fixedly connected to form a unified cavity, and the heat exchange tubes of the heat exchanger extend in...

Embodiment 2

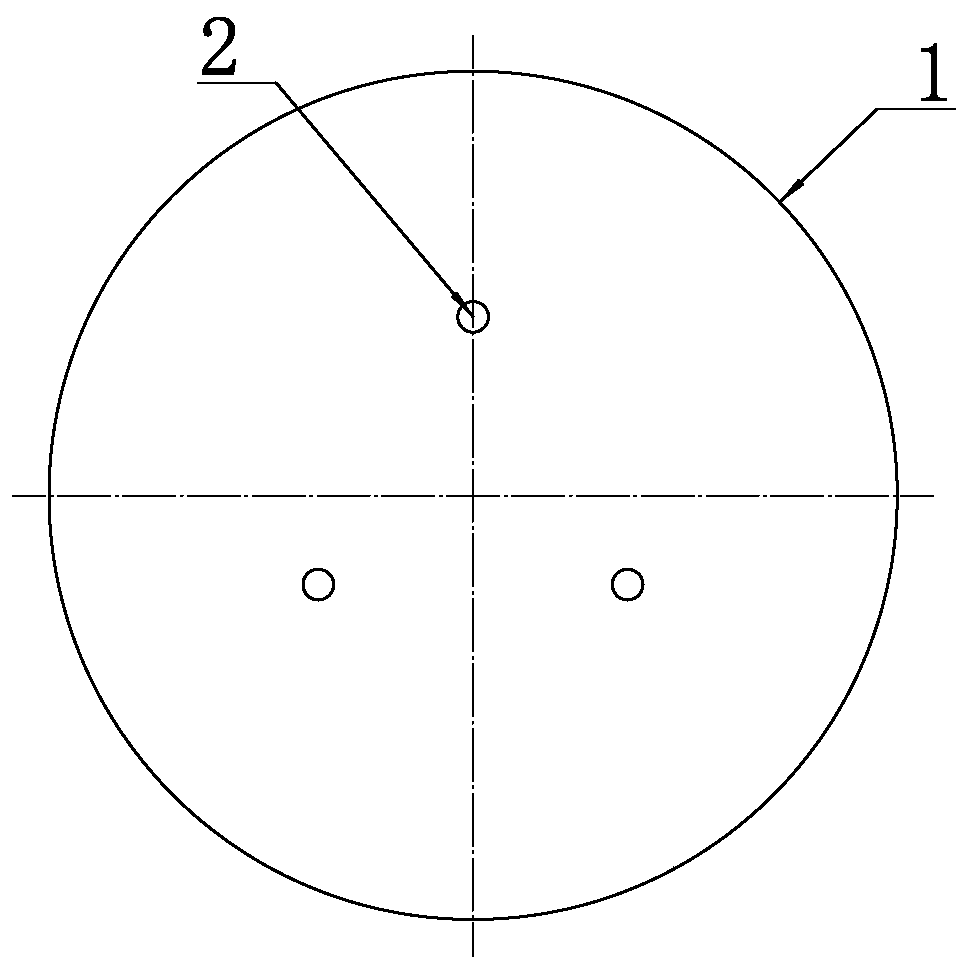

[0055] A zero electrode cylinder is arranged outside the electrodes in the upper space, and the electrodes are arranged symmetrically with respect to the center of the zero electrode cylinder in the horizontal plane, and the rest of the structure is the same as that of the first embodiment.

Embodiment 3

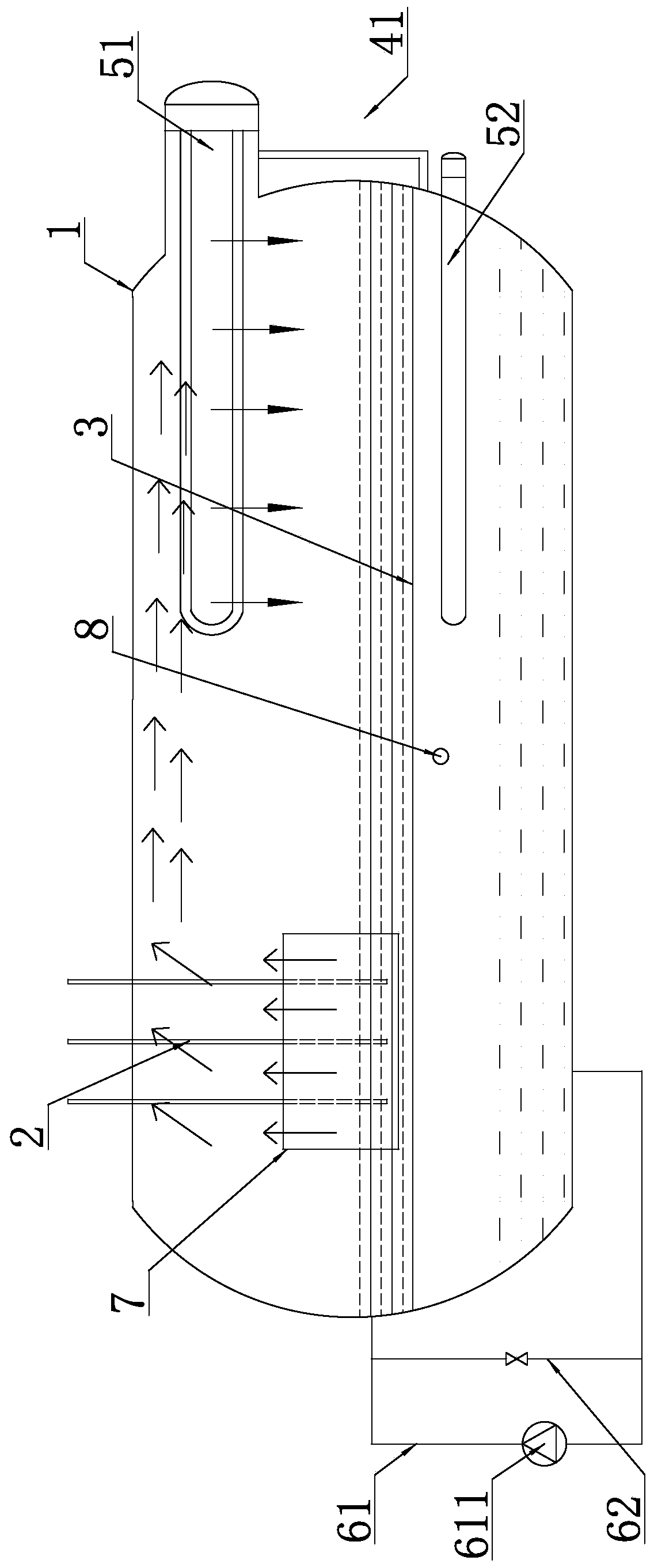

[0057] Such as image 3 As shown, a high-voltage electrode boiler includes a horizontal casing 1 filled with a certain amount of non-condensable gas. As a specific implementation, the non-condensable gas described in this embodiment contains nitrogen. A partition 3 is arranged inside the housing 1, and the partition 3 divides the inner space of the housing 1 into an upper space and a lower space.

[0058] The left end of the upper space is provided with a zero-electrode cylinder 7 with a circular cross-section, and an electrode 2 is disposed in the zero-electrode cylinder 7 . The zero electrode cylinder 7 and the electrode 2 are fixedly connected to the housing 1 respectively. The three electrodes 2 are arranged at the same height and are arranged symmetrically with respect to the center of the zero electrode cylinder 7 in the horizontal plane. That is, the projections of the electrodes 2 in the horizontal plane are sequentially connected to form an equilateral triangle, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com