Curved surface electrochromic transparent device with high efficiency and uniform color change and its preparation method

An electrochromic, electrochromic layer technology, applied in the direction of instruments, vacuum evaporation plating, coating, etc., can solve the problems of uneven film thickness, large potential drop, insufficient driving force of discoloration, etc., to achieve the realization of Uniformity, improve potential distribution, improve discoloration uniformity and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

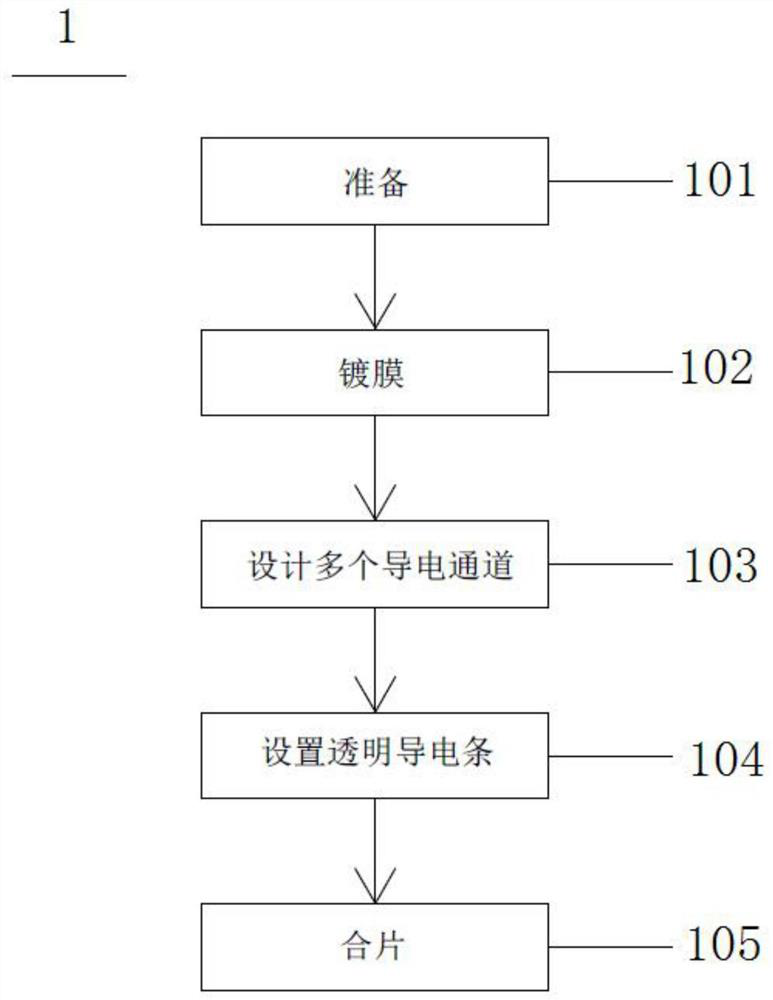

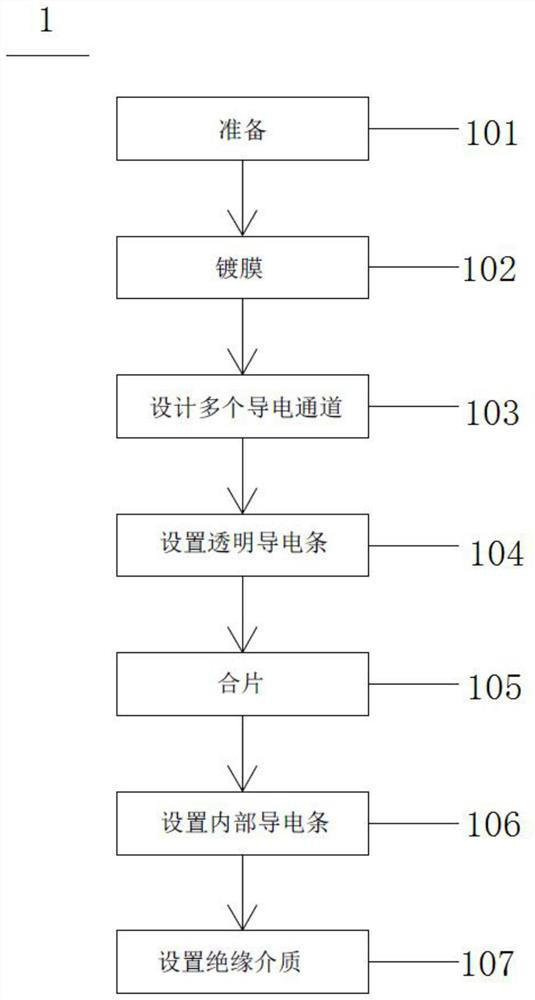

[0048] In an embodiment of the present invention, please refer to figure 1 , which shows a schematic flow chart of the steps of the manufacturing method 1 of the highly efficient and uniform color-changing curved surface electrochromic transparent device 2 according to an embodiment of the present invention. The preparation method 1 of the curved surface electrochromic transparent device 2 with high efficiency and uniform discoloration includes the following steps 101-105, wherein:

[0049] Step 101, prepare. The first substrate 21 and the second substrate 22 of the curved surface electrochromic transparent device 2 with high efficiency and uniform discoloration are pretreated and cleaned with deionized water.

[0050] Specifically, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com