Graded calendering molding method of prelithiation anode

A calendering and graded technology, applied in electrode rolling/calendering, electrode manufacturing, battery electrodes, etc., can solve the problems of expensive thin lithium foil, poor effect on lithium foil thickness and uniformity, and high cost, and achieve The thickness and uniformity are satisfied, the method is simple and easy, and the effect of reducing the thickness requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment the present invention is described in further detail:

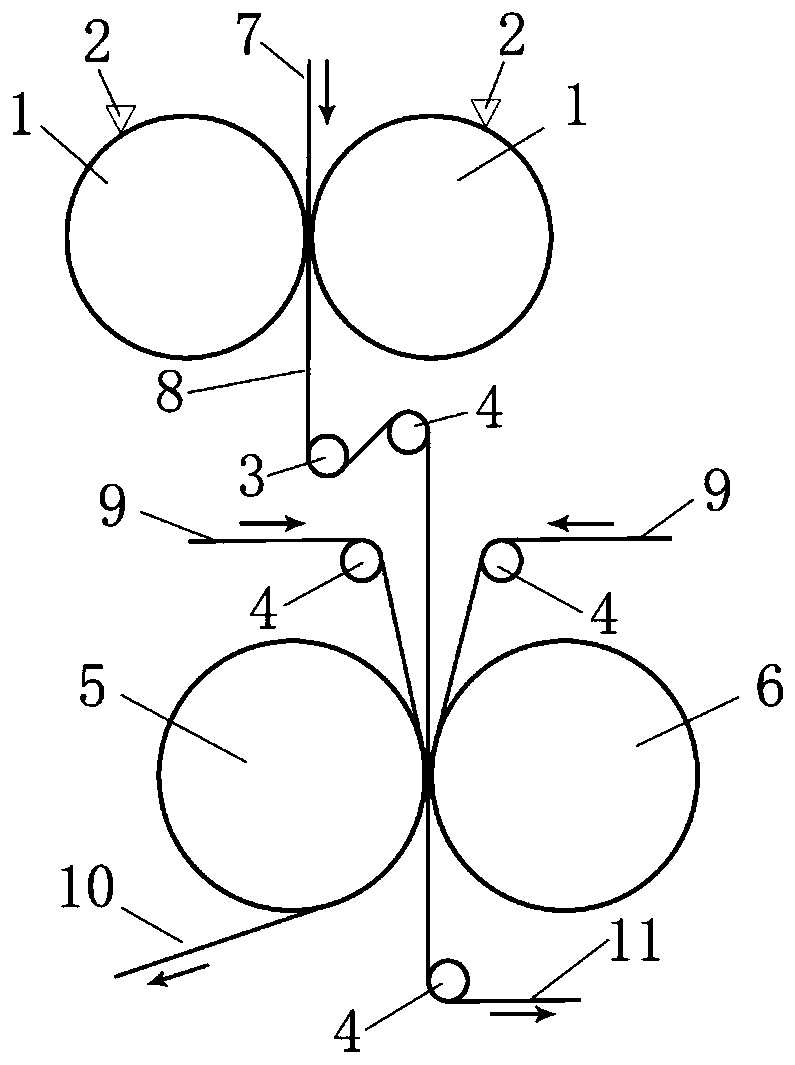

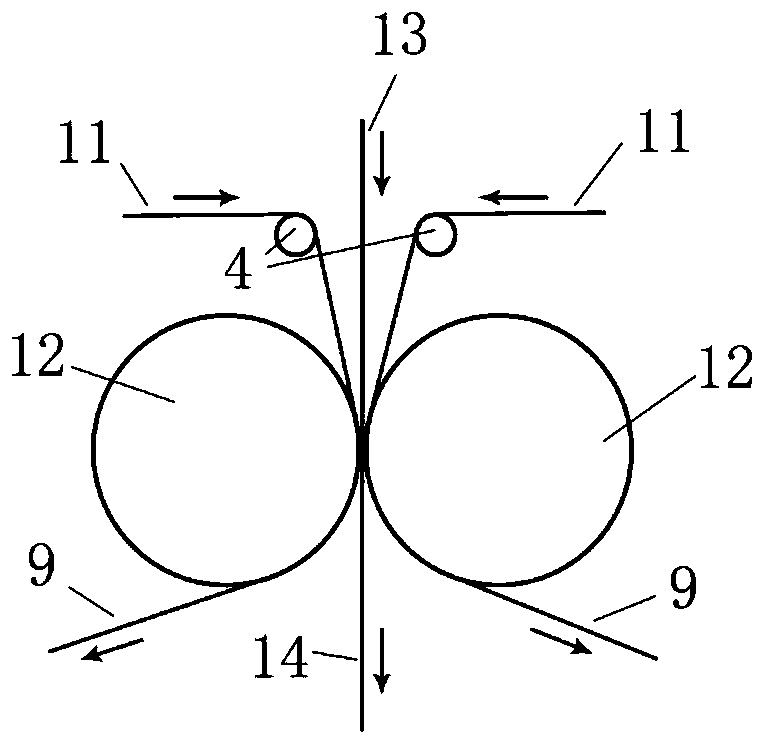

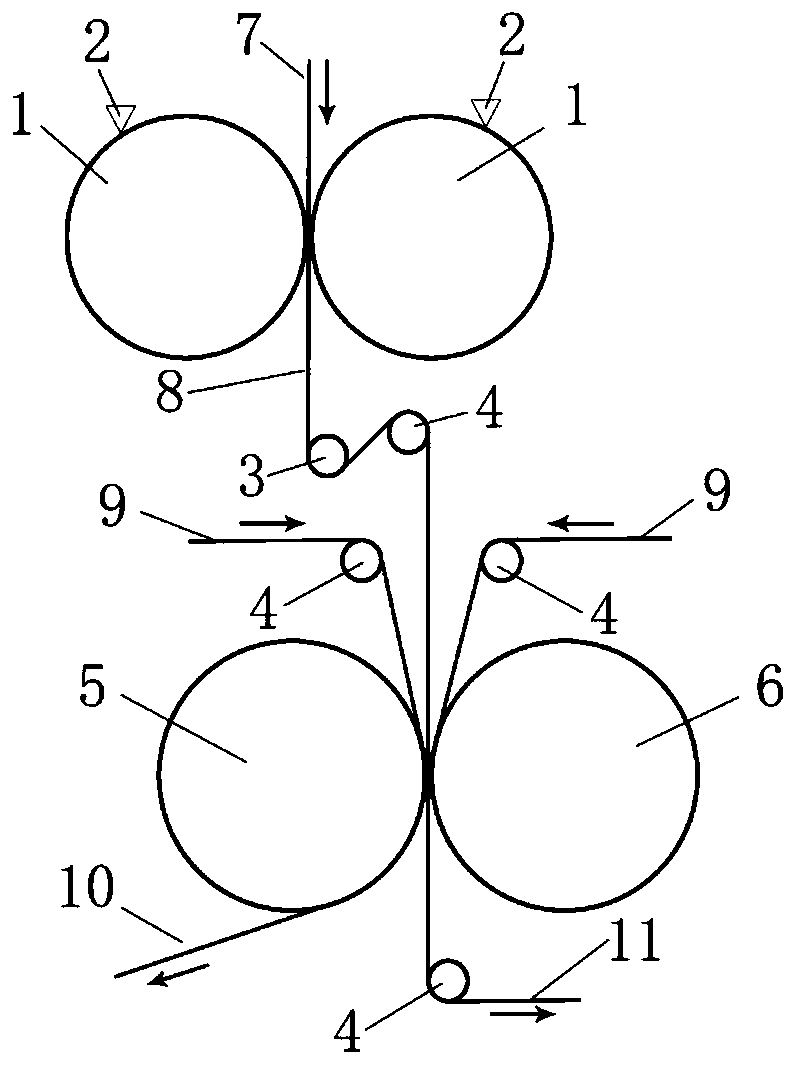

[0022] refer to figure 1 with figure 2 The shown stepwise calendering forming method of a pre-lithium negative electrode includes the following steps: a pair of pre-compression rolls 1, a pair of main press rolls and a pair of compound rolls 12 are arranged, and a pair of main press rolls includes slow rollers with different relative speeds. Roll 5 and fast roll 6, the rotational speed ratio of slow roll 5 and fast roll 6 is 0.01-1.

[0023] A silicone oil coating device 2 is provided on the adjacent side of the pre-compression roller 1 for coating a small amount of silicone oil on the roller surface to prevent the lithium belt 7 from sticking to the roller during pre-compression.

[0024] The specific coating method of the silicone oil coating device 2 can be extrusion coating, transfer coating or dip coating, and the viscosity of the silicone oil is 100-500cp.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com