Manufacturing process for thermal phase modified two-wheeled vehicle hub

A manufacturing process and modification technology, which is applied in the direction of wheel hubs, vehicle parts, transportation and packaging, etc., can solve problems such as uneven density and insufficient surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

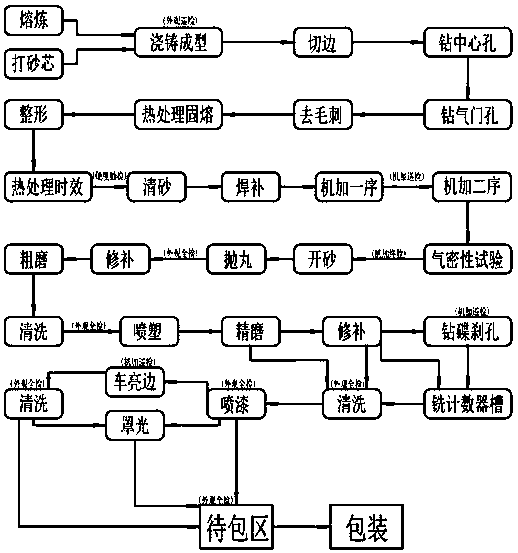

[0030] Below by embodiment, in conjunction with accompanying drawing, technical scheme of the present invention is done as preferred specific description:

[0031] Such as figure 1 As shown, a kind of manufacturing process of thermal phase modified two-wheeled wheel hub comprises the following steps:

[0032] 1. Step 1, making sand core: make a sand core mold, install the sand core mold into the sand core machine smoothly, and adjust the parallelism and verticality of the mold and the machine;

[0033] After installation, inject sand for test, the coated sand shall not be ejected from the parting surface;

[0034] Start the sand core machine to heat up, set the mold temperature of the sand core machine to 250±20°C, keep the temperature at 2°C per second and increase the temperature to 230~270°C, then keep the temperature beyond the range and immediately add the temperature to restore;

[0035] After the temperature reaches 230~255°C, add high-temperature lubricating oil to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com