Rotatable chisel plugging and unplugging device for wall body material production

A wall material, rotary drive technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of high cost of positioning mechanism, difficult maintenance, low production efficiency, etc. Space, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

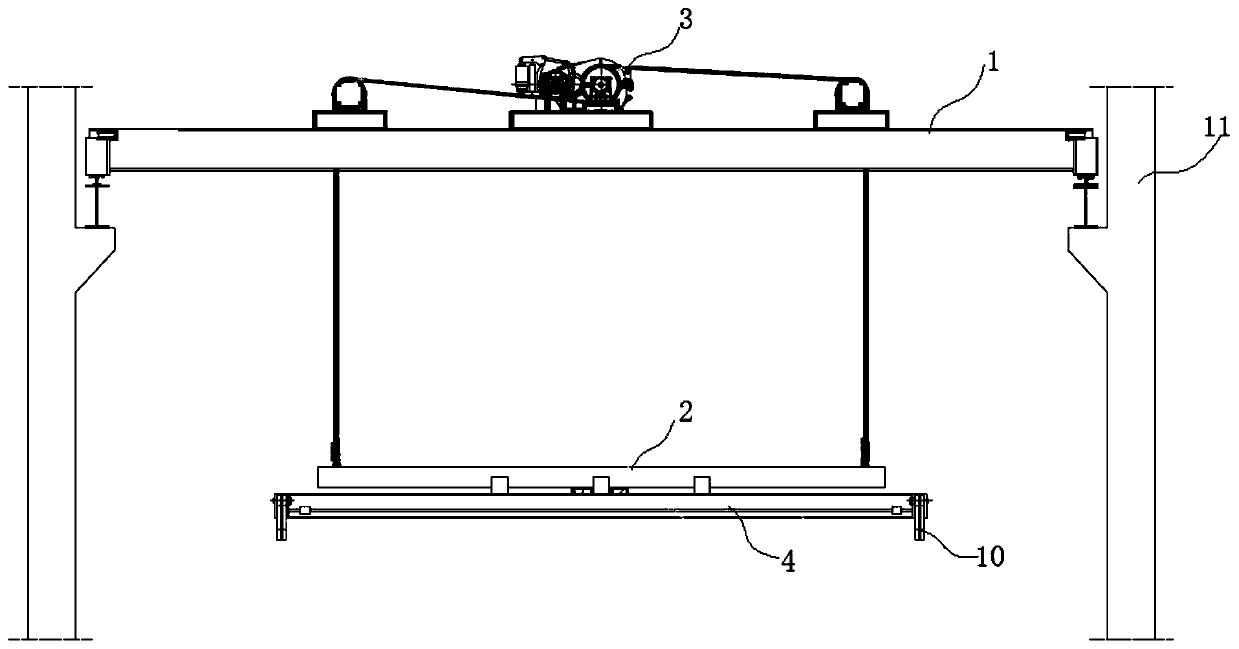

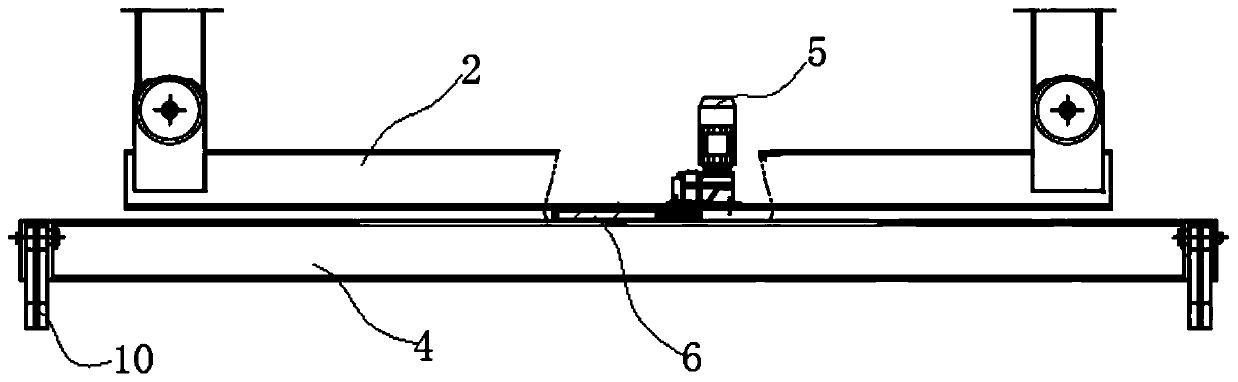

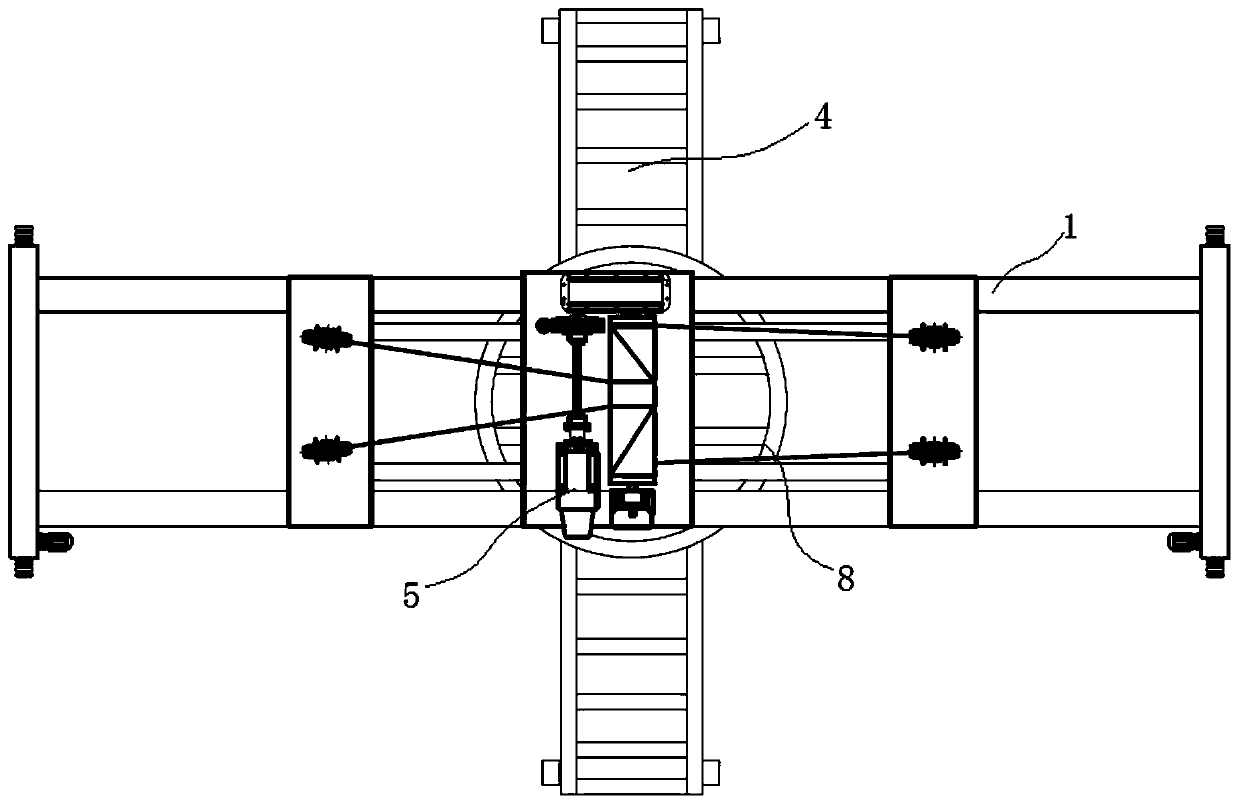

[0035] This embodiment provides a rotatable plug-in device for the production of wall materials, please refer to Figure 1-4 , the rotatable plug-in brazing device includes:

[0036] The horizontal walking vehicle frame 1 is used for reciprocating walking in the horizontal direction.

[0037] The vertical traveling frame 2 is arranged at the bottom of the horizontal traveling frame 1, and the vertical traveling frame 2 is connected with the horizontal traveling frame 1 through a lifting mechanism 3. In this embodiment, the lifting mechanism 3 It is a winch, which is used for vertically lifting the vertical traveling vehicle frame 2 to make the vertical traveling vehicle frame 2 reciprocate in the vertical direction.

[0038] The rotating saddle frame 4 is arranged at the bottom of the vertical walking support 2 and can rotate relative to the vertical walking support 2 . The two ends of the rotating saddle frame 4 are connected with clamps 10 for clamping materials.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com