polyacetal resin composition

A technology of polyacetal resin and composition, applied in the field of polyacetal resin composition, can solve the problems of use limitation, polyacetal resin does not meet the requirements, etc., and achieve the effect of less mold pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0188]

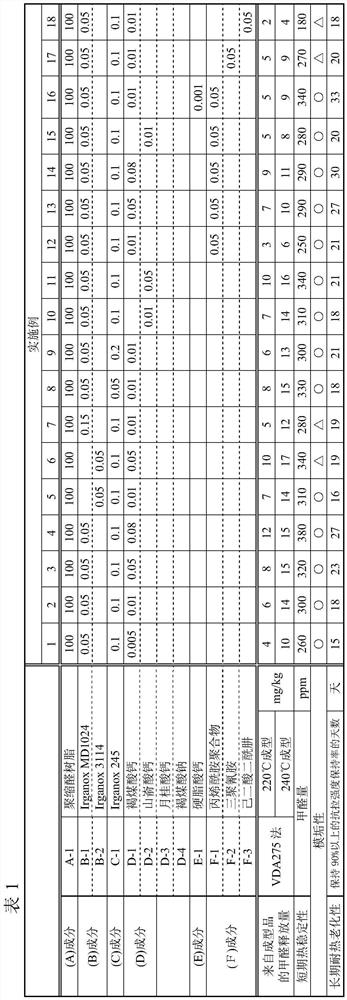

[0189] 0.05 parts by mass of the (B-1) component, 0.1 part by mass of the (C-1) component and 0.005 parts by mass and a mixture was obtained. The mixture is fed from the top feed inlet of a twin-screw extruder with a 30mm vent hole set at 200°C, under the conditions of 80rpm screw speed, exhaust decompression degree-0.09MPa, and discharge rate of 5kg / hour Melt-kneading was carried out at a temperature of 10° C. to form pellets, and then dried at a hot air temperature of 80° C. for 3 hours to prepare a pellet-like polyacetal resin composition (polyacetal resin pellets). Then, the above-mentioned measurement and evaluation were performed on the prepared polyacetal resin pellets. The results are shown in Table 1.

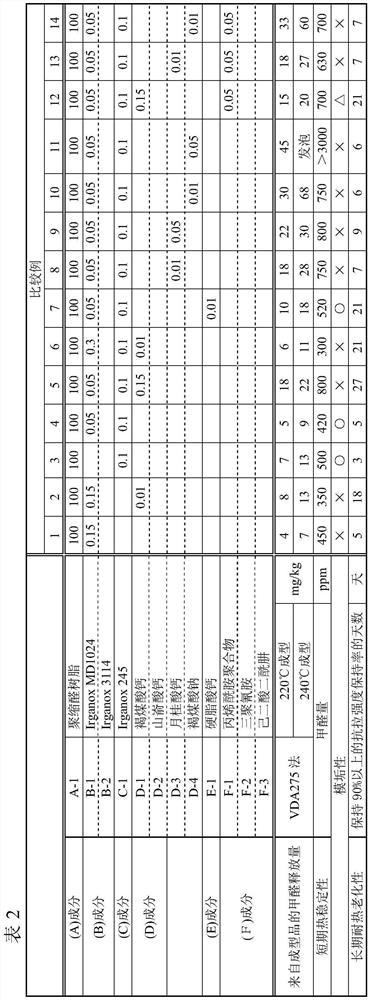

Embodiment 2~18、 comparative example 1~14

[0191] Except having set the composition as shown in Table 1 or Table 2, the same operation as Example 1 was performed, and the polyacetal resin pellet was produced. Then, the above-mentioned measurement and evaluation were performed on the prepared polyacetal resin pellets. The results are shown in Table 1 or Table 2.

[0192]

[0193]

[0194] As can be seen from Table 1 and Table 2, in Examples 1 to 18, the thermal decomposition of the polyacetal resin in a high-temperature environment is small, and the amount of formaldehyde generated from the molded article containing the polyacetal resin composition is small, and the mold contamination is also small. few. Moreover, about long-term heat aging resistance, Examples 1-18 were more favorable than the example (for example, comparative example 4) to which the fatty acid metal salt was not added. It should be noted that, from Comparative Examples 10, 11, etc., when a sodium salt is used instead of a calcium salt, at leas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com