High temperature resistant shear strength improving agent for water-based drilling fluid and preparation method thereof

A technology of water-based drilling fluid and cutting agent, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of excessive viscosity increasing effect and low temperature resistance, and increase the probability of effective interaction , low apparent viscosity, rich variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

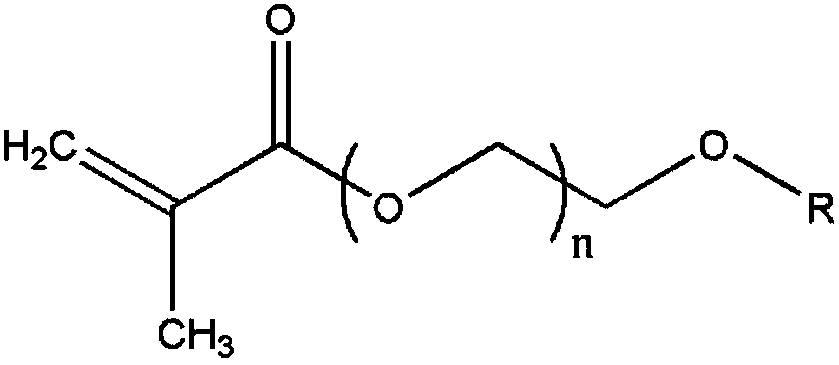

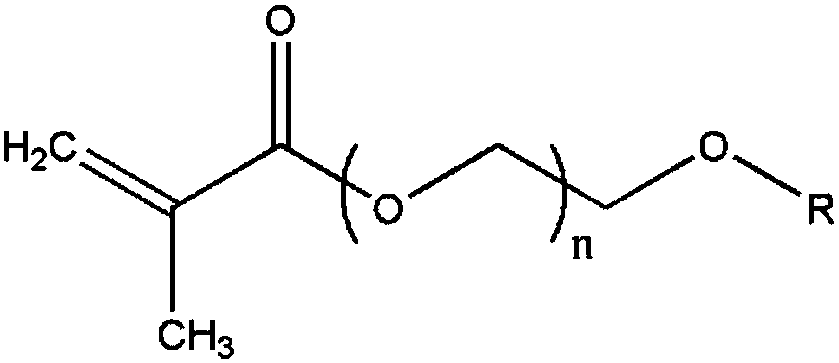

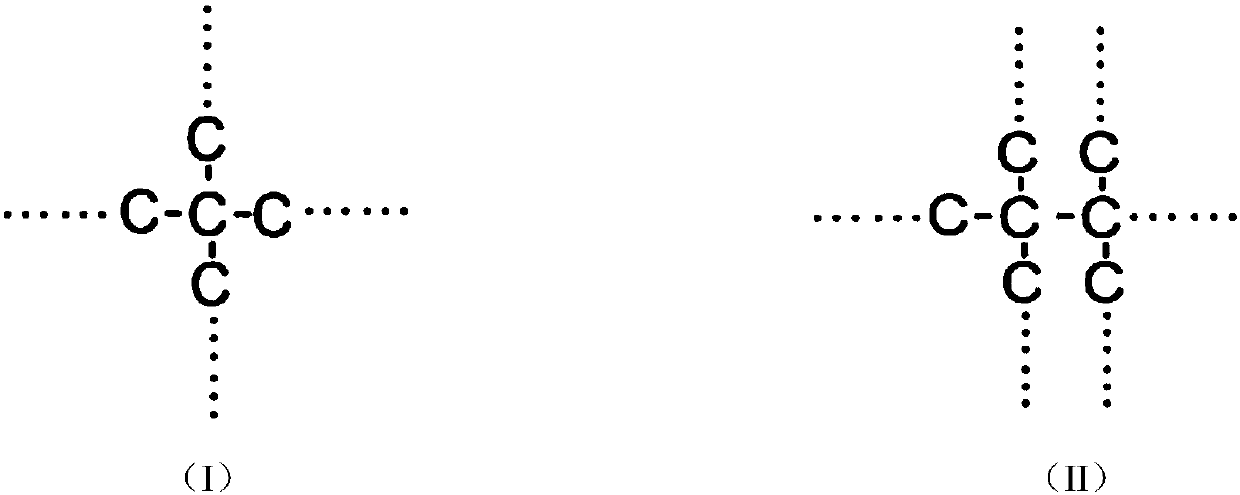

[0049] Add 800 parts of deionized water to the reaction kettle equipped with stirrer, temperature controller, air duct and reflux condenser, add 110 parts of acrylamide (monomer A), 30 parts of N-vinylpyrrolidone (monomer B), 30 parts of C18PEGMA macromer, produced by Evonik Industrial Group (monomer D) and 30 parts of methacryloyloxyethyltrimethylammonium chloride (monomer C), stirred with 30% hydrogen The sodium oxide solution adjusted the pH value of the monomer solution to 9, and finally added 2 parts of pentaerythritol and stirred until the pentaerythritol was completely dissolved.

[0050] Start the temperature control device, control the temperature of the monomer solution to 50°C, and at the same time, pass nitrogen gas under stirring for 40 minutes, then add 7 parts of ammonium persulfate, and react for 5 hours. After the reaction is finished, cool to room temperature, discharge, cut, dry, and pulverize, and the obtained powder product is the temperature-resistant wat...

Embodiment 2

[0052] Add 800 parts of deionized water to the reaction kettle equipped with stirrer, temperature controller, air duct and reflux condenser, add 110 parts of acrylamide (monomer A), 30 parts of N-vinylpyrrolidone (monomer B), 30 parts of C18PEGMA macromer (monomer D) and 30 parts of methacryloxyethyltrimethylammonium chloride (monomer C), after stirring evenly, adjust the monomer with 30% sodium hydroxide solution The pH value of the solution was 9, and finally 2 parts of dipentaerythritol was added and stirred until the dipentaerythritol was completely dissolved.

[0053] Start the temperature control device, control the temperature of the monomer solution to 50°C, at the same time, pass nitrogen gas under stirring for 40 minutes, then add 8 parts of ammonium persulfate, and react for 5 hours. After the reaction is finished, cool to room temperature, discharge, cut, dry, and pulverize, and the obtained powder product is the temperature-resistant water-based drilling fluid cut...

Embodiment 3

[0055] Add 800 parts of deionized water to the reaction kettle equipped with stirrer, temperature controller, air duct and reflux condenser, add 160 parts of acrylamide (monomer A), 20 parts of N-vinylpyrrolidone (monomer B), 10 parts of C18PEGMA macromer (monomer D) and 10 parts of methacryloyloxyethyltrimethylammonium chloride (monomer C), after stirring evenly, adjust the monomer with 30% sodium hydroxide solution The pH value of the solution was 9, and finally 2 parts of pentaerythritol was added and stirred until the pentaerythritol was completely dissolved.

[0056] Start the temperature control device, control the temperature of the monomer solution to 50°C, and at the same time, pass nitrogen gas under stirring for 40 minutes, then add 7 parts of ammonium persulfate, and react for 5 hours. After the reaction is finished, cool to room temperature, discharge, cut, dry, and pulverize, and the obtained powder product is the temperature-resistant water-based drilling fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com