Intelligent whole-process spinning system with function of sorting and circularly recovering lap waste

An intelligent spinning and intelligent technology, which is applied in the field of the whole process intelligent spinning system, can solve the problems that affect the collection, payment, transportation, collection and packaging of the return flowers, blockage of the return return transportation pipeline, and the need for manual work, etc., to achieve smooth and continuous return return collection Effects of transportation, reduction of raw material cost, and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

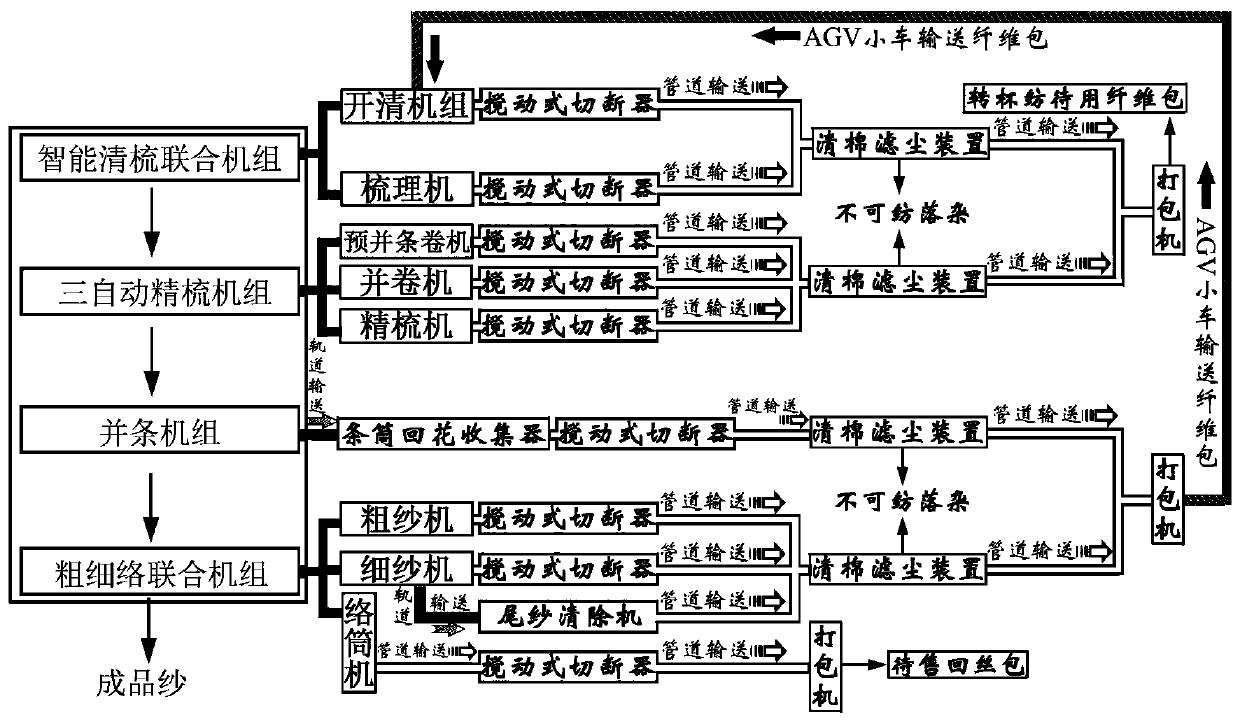

[0019] Example 1: A full-process intelligent cashback collection and payment system for a 100,000-spindle intelligent spinning mill

[0020] In Wuhan Yudahua Textile Co., Ltd., a subsidiary of Wuhan Yudahua Textile and Garment Group Co., Ltd., the 60,000-spindle traditional ring spinning workshop on the second floor of the original factory building was retained and transformed, and 4 newly developed Jingwei spinning machines were introduced. Rotor spinning long car; a 100,000-spindle intelligent spinning factory was built on the first floor of the original factory building. The intelligent spinning system in the factory all adopts the intelligent cleaning and carding unit, three automatic combing units, The drawing frame unit, the thick and fine linking unit, and the intelligent logistics and transportation system between the units, the SFU150G type return baler of Jiangyin Zhengming Textile Machinery Co., Ltd. Four JYDL-36-L multi-cage cotton cleaning dust filter devices prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com