A method for improving peat soil foundation by microbial technology

A microbial technology and soil foundation technology, which is applied in the field of peat soil foundation improvement by microbial technology, can solve problems such as large vibration and noise, poor drainage and consolidation effect, and impact on buildings and the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

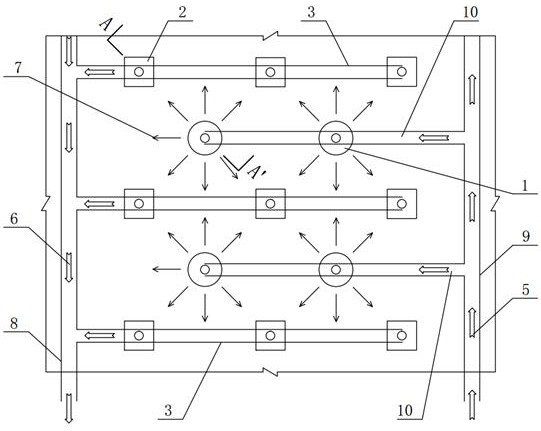

[0022] Embodiment 1: as Figure 1~2 As shown, a method for improving peat soil foundation by microbial technology, the specific steps are as follows:

[0023] (1) Level the site, and then lay out 9 pumping wells 2 and 4 water injection wells 1 in the peat soil foundation to be treated. The 9 pumping wells 2 are divided into three rows and arranged in a rectangular shape, with 3 pumping wells in each row. For water wells, four water injection wells 1 are arranged in two rows, and each row of water injection wells 1 is respectively located in the center of two adjacent rows of pumping wells 2;

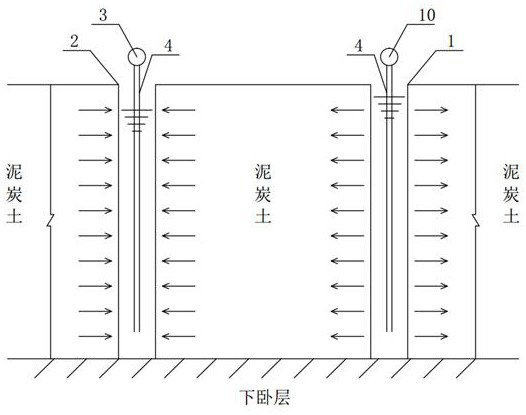

[0024] (2) Each row of pumping wells 2 is connected to the PVC main pipe Ⅰ3 through the PVC branch pipe 4, and the PVC main pipe Ⅰ3 in each row is connected to the PVC main pipe Ⅱ8 to form an independent pumping system. The water injection well 1 in each row is connected to the PVC main pipe 4 through the PVC branch pipe 4. The PVC main pipe Ⅲ10 is connected, and the PVC main pipe Ⅲ10 o...

Embodiment 2

[0039]Embodiment 2: This embodiment is the same as Embodiment 2, the difference is that the amplified bacteria liquid 5 is preferably amplified from the foundation soil by native microorganisms, injected from the water injection system, extracted by the pumping system, and injected into the water injection well 1 There is a water head difference between the pumping well 2, so that the amplified bacterial solution 5 forms seepage in the peat soil to be treated, flows evenly through the peat soil layer to be treated, the bacteria are adsorbed in the soil, and the nutrient solution is injected through the water injection well 1 to maintain the soil. The number and activity of microorganisms in the In addition, soil samples are taken regularly to detect the number of bacteria in the soil, and if necessary, the number of bacteria in the soil can be supplemented by injecting a high-concentration bacterial solution.

Embodiment 3

[0040] Embodiment 3: This embodiment is the same as Embodiment 2, the difference is that the amplified bacteria liquid 5 is amplified by the introduction of foreign microorganisms, injected from the water injection system, extracted by the pumping system, and injected into the water injection well 1 and the pumping system. A water head difference is formed between the two wells, so that the amplified bacterial liquid 5 forms seepage in the peat soil to be treated, flows evenly through the peat soil layer to be treated, the bacteria are adsorbed in the soil, and the nutrient solution is injected through the water injection well 1 to maintain the microorganisms in the soil. In addition, soil samples are taken regularly to detect the number of bacteria in the soil, and if necessary, the number of bacteria in the soil can be supplemented by injecting a high-concentration bacterial solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com