Method for realizing pressure P-displacement characteristic of bellows vacuum capsule

A technology of vacuum bellows and bellows, applied in the direction of elastic deformation gauge type fluid pressure measurement, etc., can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

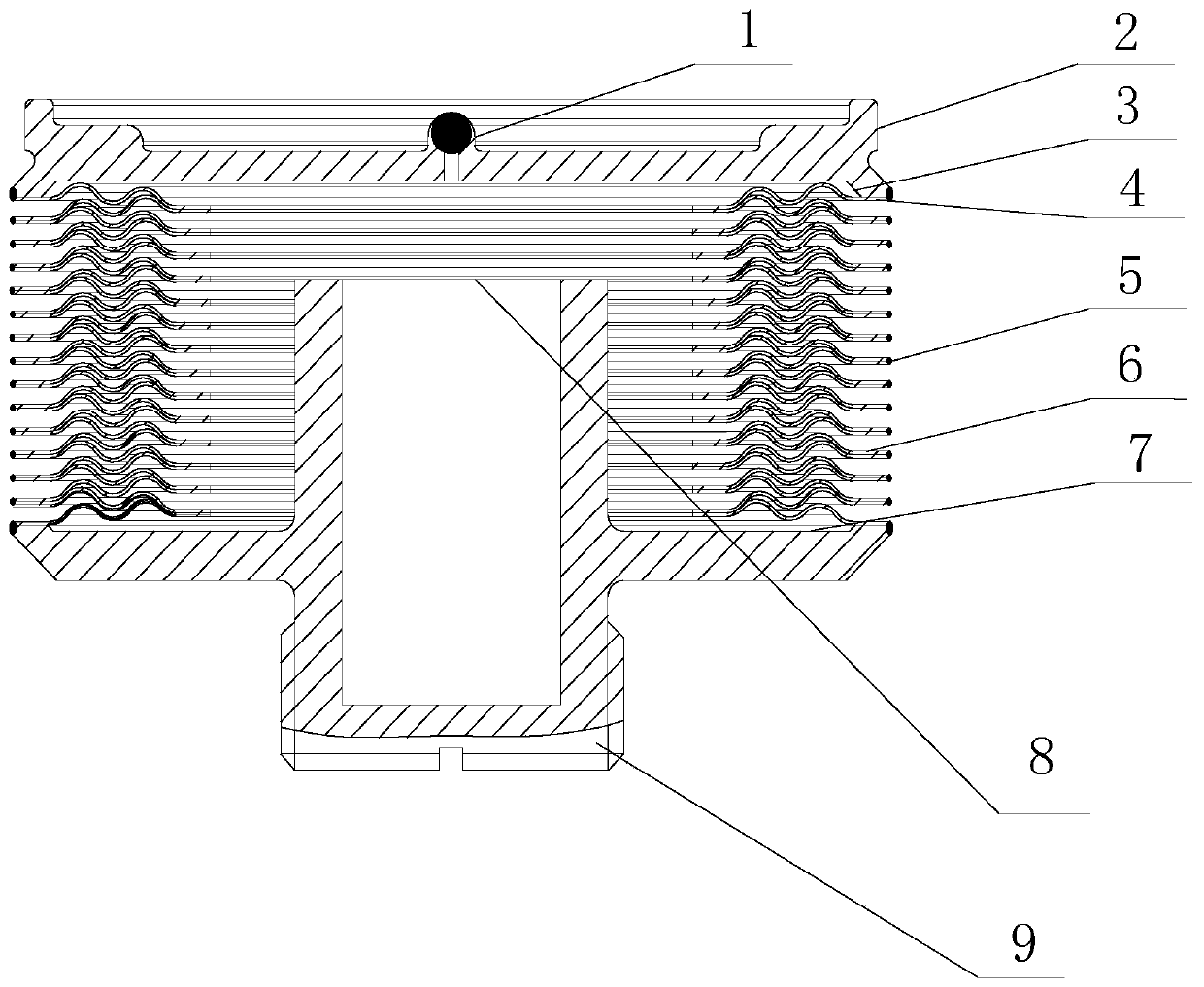

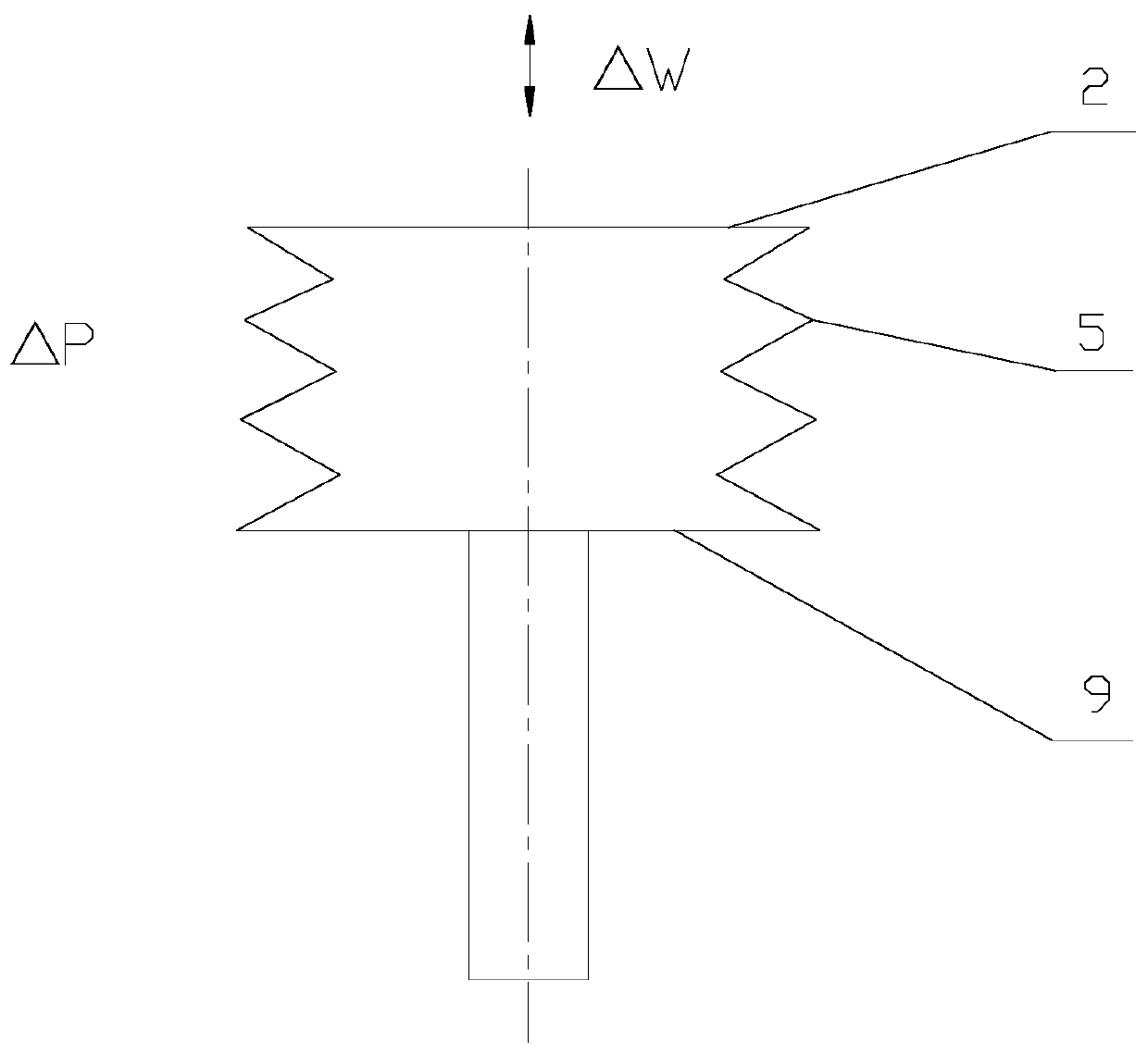

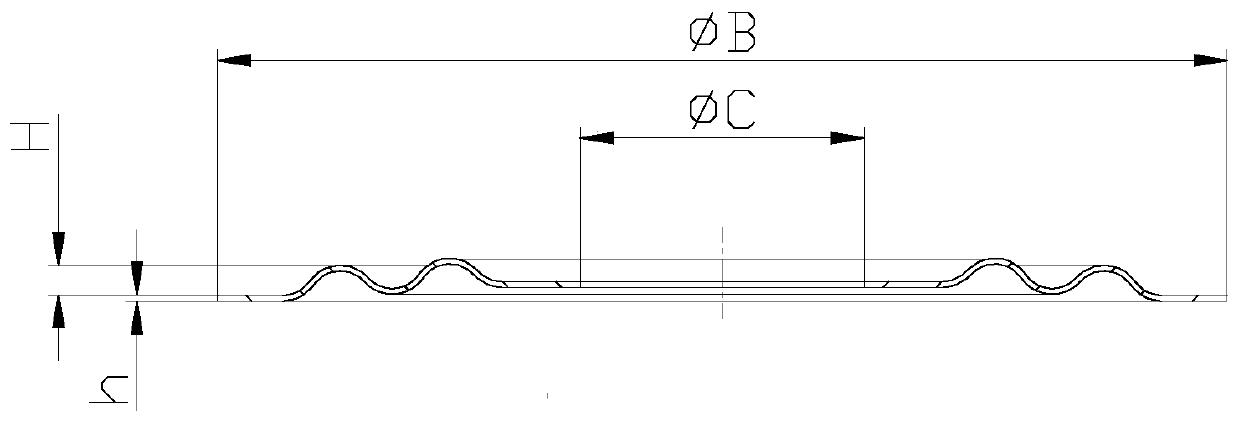

[0023] refer to figure 1 , figure 2 . According to the present invention, with a single welded bellows as the elastic sensitive element, through K` P =P / W, convert the pressure P-displacement W characteristic required by the vacuum bellows into the uniform force stiffness K` of the vacuum bellows P , determine the material and elastic modulus E, and according to the external dimensions that the vacuum bellows needs to meet, design the outer circle radius R of the wave plate and the radius r of the inner hole of the wave plate, and preliminarily give and try to calculate the thickness h of the wave plate and the wave number Value n, wave height value H, determine wave depth coefficient k by k=R / r, by k 1 =H / h determines the wave height coefficient k 1 , check and other arc-shaped bellows f 0 , Graph to obtain dimensionless stiffness Dimensionless effective area f 0 ,Depend on Calculation of the effective area A of the welded bellows vacuum bellows 0 , by K f = π...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circle radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com