Program-controlled oil quantity and oil temperature simulation device

A simulation device and technology of program-controlled fuel volume, which is applied in the field of oil temperature signal simulation and aircraft fuel volume, can solve the problems of large measurement error, inconvenience, cumbersome operation, etc., and achieve high work efficiency, avoid measurement error, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

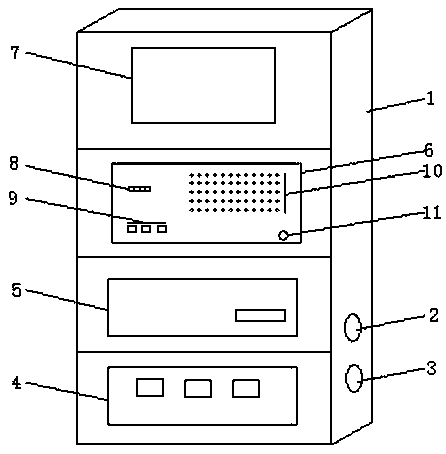

[0029] The present invention is realized through the following technical solutions, as Figure 1-5 As shown in the figure, a program-controlled oil quantity and temperature simulation device is electrically connected to the fuel signal conversion box, including a standard cabinet 1, and also includes a test cable interface 2 integrated in the standard cabinet 1, an equipment power interface 3, and a regulated DC power supply. 4. Industrial computer 5, program-controlled capacitor box 6, display 7; the test cable interface 2 and the equipment power interface 3 are arranged outside the standard cabinet 1, and the equipment power interface 3 is connected to the regulated DC power supply 4; the regulated voltage The DC power supply 4 is connected to the industrial computer 5, the program-controlled capacitor box 6, and the display 7;

[0030] It should be noted that, through the above improvements, the present invention proposes a program-controlled oil volume and oil temperature ...

Embodiment 2

[0034] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the program-controlled capacitor box 6 is provided with an operation panel, and the operation panel includes a dial switch 8, a key switch 9, a light emitting diode 10, and a power switch 11; the key switch 9 includes a check switch, a self-check switch , Reset switch.

[0035] It should be noted that, through the above improvements, the operation panel of the program-controlled capacitor box 6 is provided with a dial switch 8, which is used to output the capacitance and resistance of the corresponding gear when the program-controlled capacitor box 6 is checked, and the dial switch 8 There are four combinations, namely 0001, 0010, 0100, 1000. The key switch 9 is used for the verification, self-inspection and reset functions of the program-controlled capacitor box 6, including a verification switch, a self-inspection switch, and a reset switch. The light emitting diod...

Embodiment 3

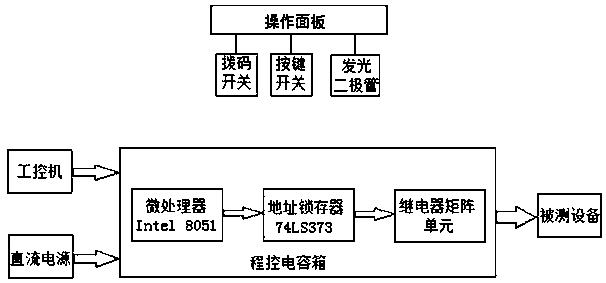

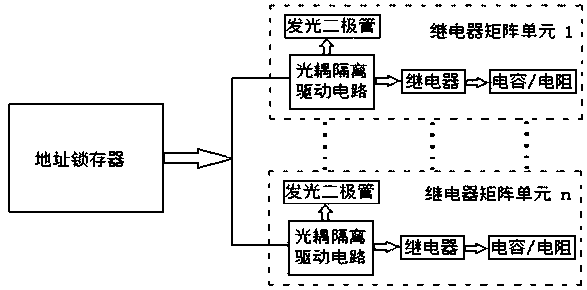

[0038] This embodiment is further optimized on the basis of the above embodiments, such as Figure 2-3As shown, the program-controlled capacitor box 6 includes a microprocessor, an address latch, and a relay matrix unit connected in sequence, the microprocessor is connected to the industrial computer 5, and the relay matrix unit is connected to the fuel signal through the test cable interface 2 Switching box is electrically connected; the microprocessor adopts 8051 single-chip microcomputer; the model of the address latch is 74LS373, and the address latch is connected with the 8051 single-chip microcomputer; the quantity of the relay matrix unit is multiple, and all with The address latch is connected; each relay matrix unit includes an optocoupler isolation drive circuit, a relay, and a standard capacitor connected in sequence.

[0039] It should be noted that, through the above improvements, the verification process of the simulation device: after the simulation device is po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com