Nano-imprinting device capable of preparing complex microstructure

A nano-imprint and micro-structure technology, which is applied in the direction of photomechanical equipment, pattern surface photolithography, optics, etc., to reduce costs, improve production efficiency, and reduce alignment and loading and unloading errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

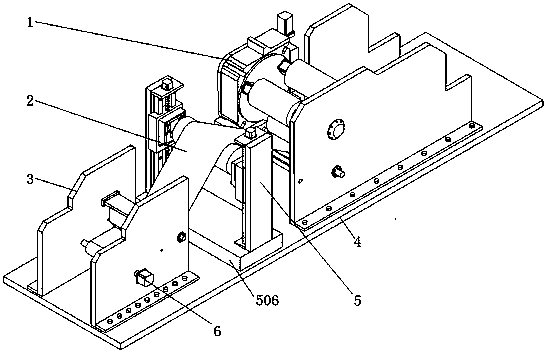

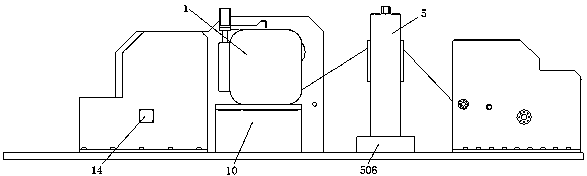

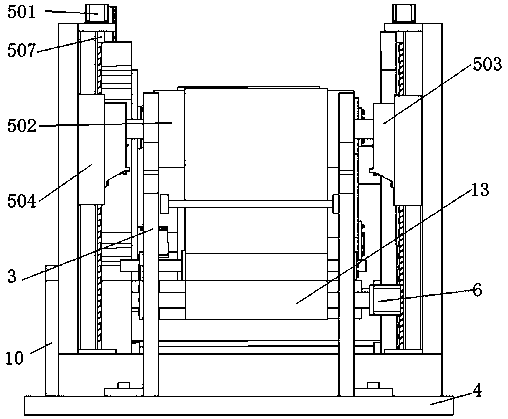

[0032] Such as figure 1 , figure 2 , image 3 , Figure 8As shown, the nanoimprinting device capable of preparing complex microstructures includes an imprinting device 1, a substrate 2, a frame 3, a bottom plate 4, an adjustment device 5, a servo motor 6, a winding roller 7, an engraved Erosion device 8, heating roller 9, loading block one 10, support roller 11, gluing device 12, unwinding roller 13, servo motor two 14. The frame 3 is connected to the bottom plate 4 by screws, the winding roller 7, the heating roller 9, the support roller 11, and the unwinding roller 13 are all fitted on the frame 3 through bearings, and the gluing box 1201 is fixed by screws On the frame 3, the servo motor 1 6 is connected with the unwinding roller 13, the servo motor 2 14 is connected with the winding roller 7, and the winding roller 7 and the unwinding roller 13 rotate synchronously, so that the substrate 2 advances smoothly, and the servo motor The first 6 and the servo motor two 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com