Method for improving mechanical processability of titanium alloy

A processing performance, titanium alloy technology, applied in the field of improving the mechanical processing performance of titanium alloys, can solve problems such as material failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The method for utilizing hydrogen to improve the mechanical processing properties of titanium alloy comprises the following steps:

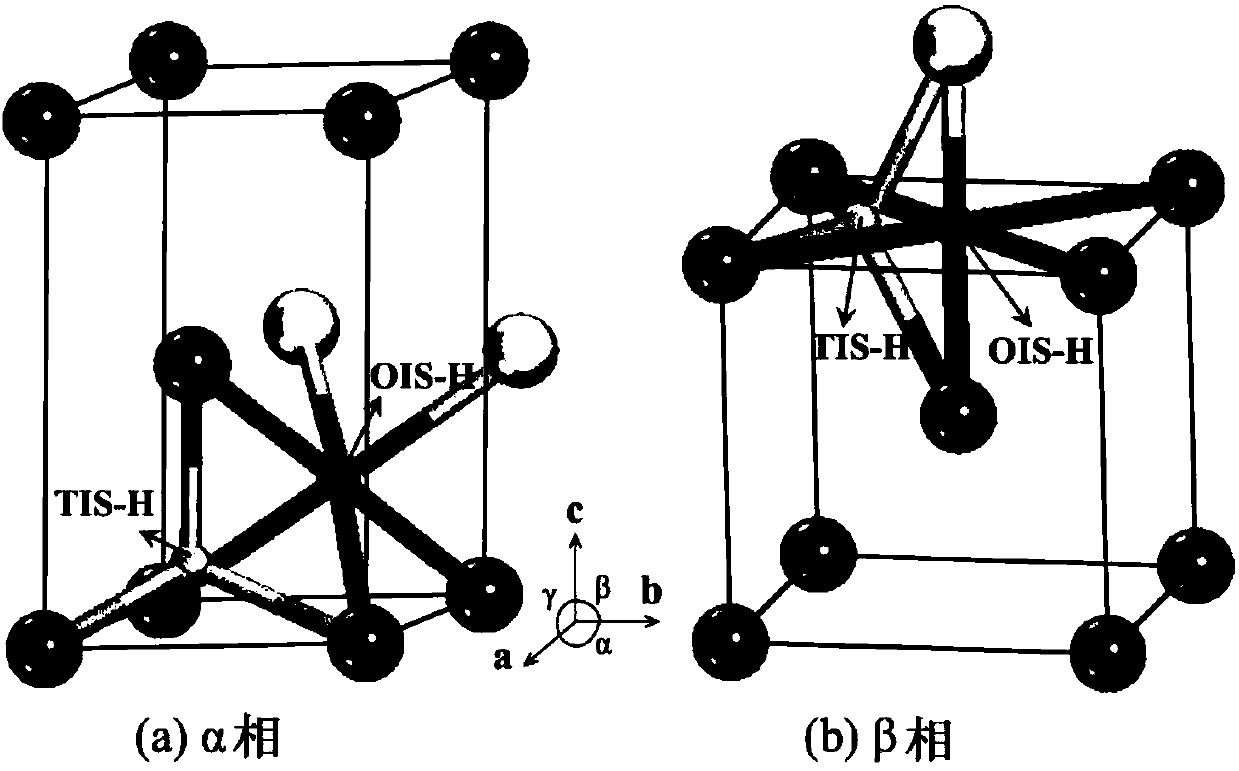

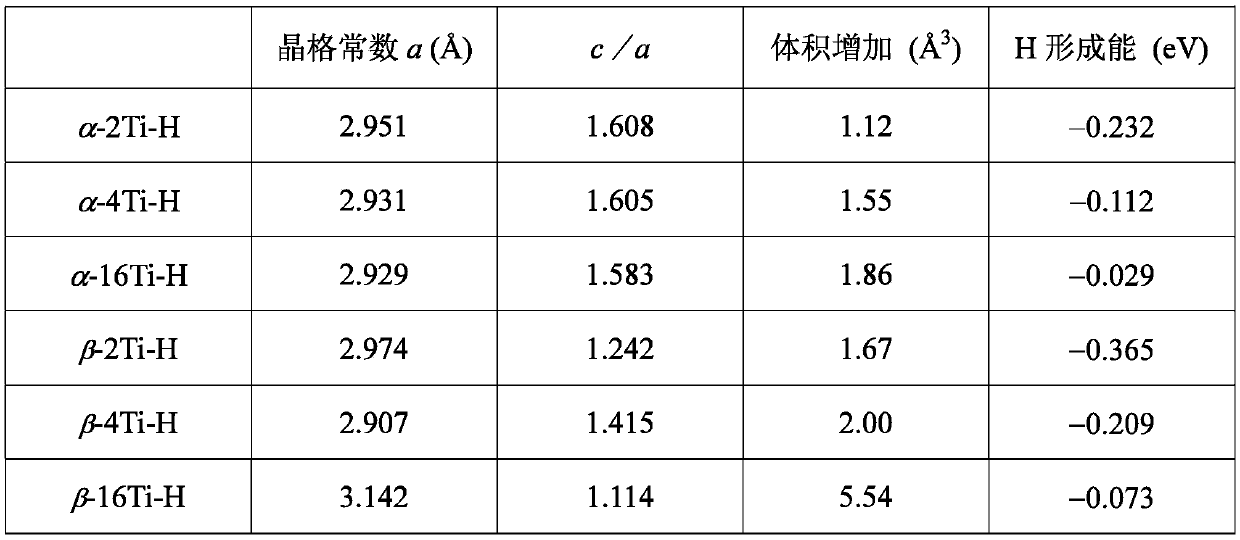

[0019] 1. Obtain the thermodynamic stability of hydrogen in titanium: the atomic structures of α-phase titanium and β-phase titanium are close-packed cubic structure and body-centered cubic structure respectively. First, in order to determine the thermodynamic stable position of hydrogen, H is placed in figure 1 The two gap positions in , calculate the thermodynamic formation energy of H, and judge the stable position of H. Further, in order to simulate and calculate different H concentrations, a supercell containing different Ti atoms is established by extending the original cell containing 2 Ti atoms for different periods in the three directions of x, y, and z. For example, Ti 16 The supercell is made of (2×2×2) Ti 2 Primary cell composition, Ti 8 Supercell (2×1×2) Ti 2 primitive cells, and so on. Put one H atom into the above unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com