Pneumatic method for separating mineral raw materials

A technology for mineral raw materials and raw materials, which is applied in solid separation, chemical instruments and methods, and separation of solids from solids by air flow. The effect of improving selectivity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

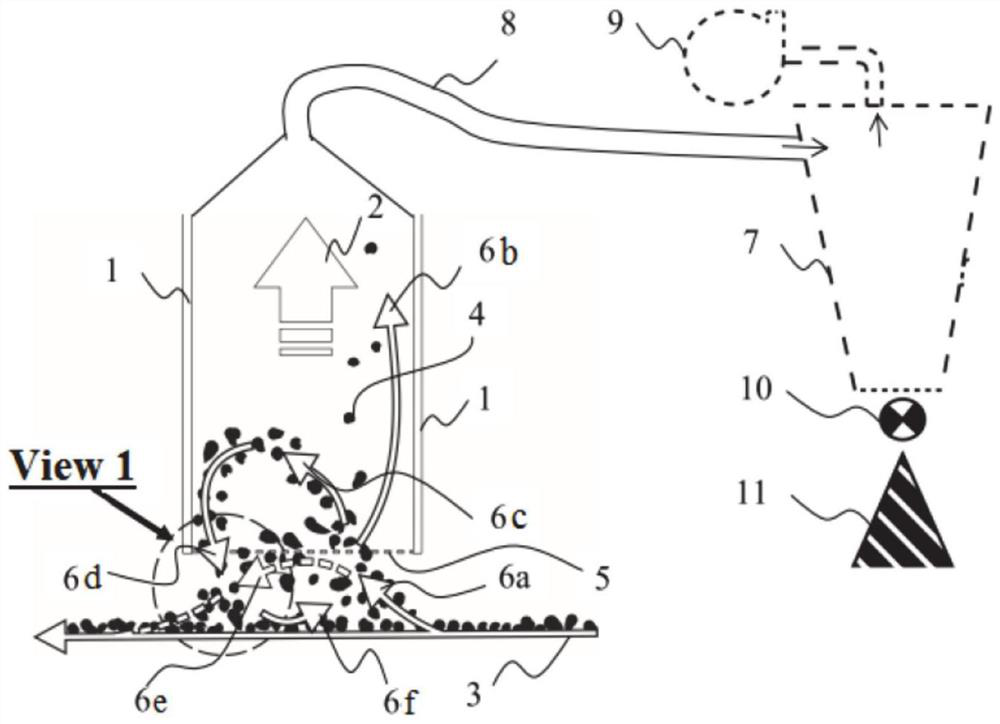

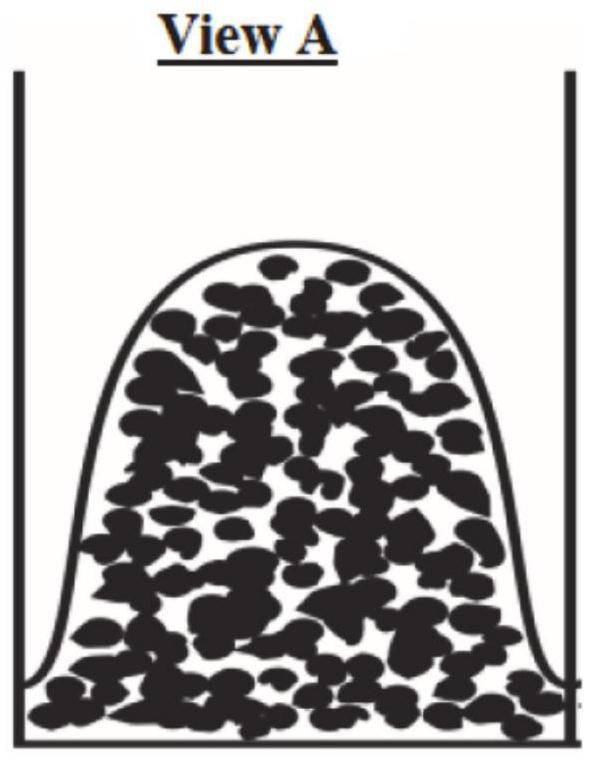

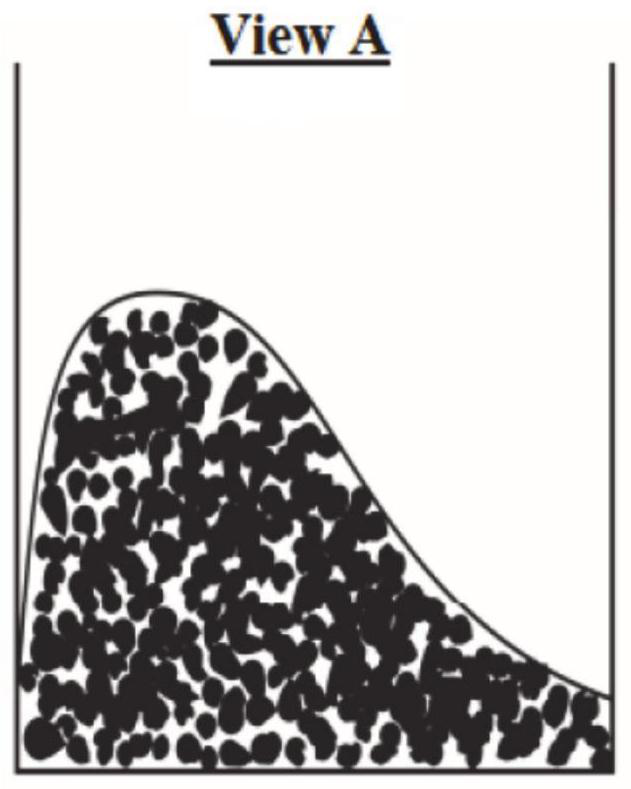

[0033] In order to understand the claimed method, first, let us consider the processes that take place in a split vertical chamber, as figure 1 As shown, the particles 4 of the raw material are separated and moved within the air-permeable belt conveyor 3 . The smallest fraction of particles is filtered by conveyor 3 and removed from the particle separation area (the process of filtering and conditionally removing spilled particles by conveyor 3 is not shown schematically). Next, the particles 4 moving on the conveyor 3 reach the entry area of the separating vertical chamber, defined by the wall 1 , where the particles 4 and the air flow 2 are sucked through its open bottom opening 5 . Thus, in the area adjacent to the open bottom 5 of the separating vertical chamber, a vortex of moving particles 6a-6e occurs, formed by the simultaneous impact of the particles 4 by horizontal energy, which is in line with their movement on the belt conveyor 3 and The vertical lift force cre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com